jvb

Member

- Joined

- Nov 28, 2018

- Messages

- 8

- Reaction score

- 0

Hi Folks.

I'm new to this site. I started brewing a couple of years ago and had some pretty good batches. All of my beers have used malt extracts, some grain additions, and dry yeasts. Unfortunately, I had two batches that were undrinkable, which kind of dampened my enthusiasm. I think my problem with the bad batches had to do with recipes that were a little vague and failure on my part to use correct procedures (one was a lager, which I think went south during fermentation).

Long story short - I pushed the reset button and ordered a couple of Midwest Brewing Supplies "Beer, Simply Beer" kits (no specialty grains). Before starting, I wanted to get some feedback on some basic questions:

Thanks,

Jim

I'm new to this site. I started brewing a couple of years ago and had some pretty good batches. All of my beers have used malt extracts, some grain additions, and dry yeasts. Unfortunately, I had two batches that were undrinkable, which kind of dampened my enthusiasm. I think my problem with the bad batches had to do with recipes that were a little vague and failure on my part to use correct procedures (one was a lager, which I think went south during fermentation).

Long story short - I pushed the reset button and ordered a couple of Midwest Brewing Supplies "Beer, Simply Beer" kits (no specialty grains). Before starting, I wanted to get some feedback on some basic questions:

- Should I boil the wort covered or uncovered? It seems like I lose a lot of wort volume if the pot is uncovered due to boil-off.

- Should I add hop pellets directly into the wort or should I put them in a muslin bag? If I don't put the hops in a bag, do I need to strain the wort prior to fermentation?

- Should I always strain the wort prior to fermentation or are the instances where I wouldn't want to?

- Do I need to hydrate dry yeast before adding to the wort? If so, what procedure should I use?

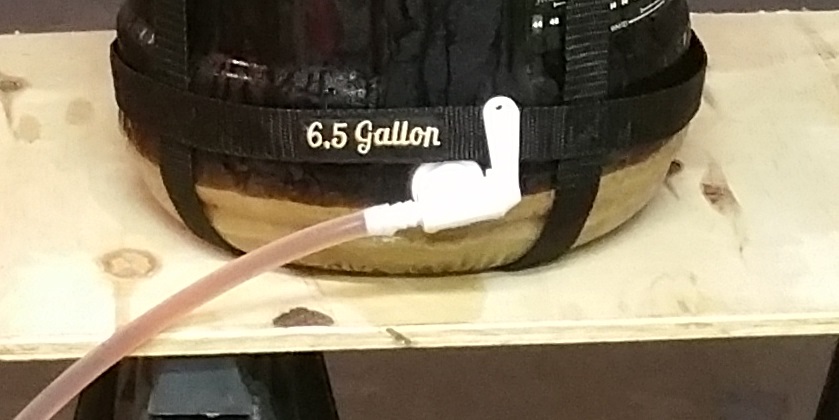

- I've been using a glass carboy for fermentation and have never used secondary fermentation although it seems like a lot of recipes call for it. I picked up a 6.5 gallon bucket fermenter and I was going to add a spigot to the bottom of the bucket to aid in transfer to the secondary fermenter. If I do this, how far off the bottom of the bucket should I place the spigot? When transferring the beer from primary to secondary, should the transfer hose be close to the bottom of the secondary fermenter or would it be ok to terminate the hose at the top of the secondary fermenter?

Thanks,

Jim