Good day fellow brewers! I want to share my recently completed electric brewery build with you guys and gals as all of the build threads I have read here on homebrewtalk.com have really inspired me and helped me along the way. I really look forward to following these threads.

I am a retired electronic systems engineer and started brewing after I took an early retirement in February 2014. I've always been curious about how brewing beer works but never had the time to invest in it. I started with extract kits and soon realized that all-grain was the way to go.

I started planning the brewery in September 2014 and began acquiring parts soon after that. Construction started in January 2015 and is pretty much complete as of June 2015. I am fortunate to have a very supportive SWMBO and the time and resources to devote to this project. I did all the work myself except for help with the ceramic tile which my son does for a living.

Thanks to everyone on these forums for all the terrific ideas, answers and solutions to problems you all have. I've learned so much following you all. Special thanks for some really good ideas and products goes out to the following folks as I used your products, ideas and inspiration...

Vendors:

http://www.auberins.com

http://www.brewershardware.com

http://www.brewhardware.com

http://www.ebrewsupply.com

http://www.stainlessbrewing.com

http://www.stilldragon.com

http://www.theelectricbrewery.com

http://www.zchillers.com

Forum Member Builds:

@azwillnj

@CptMidway

@Docbruw

@highland_brewer

@hunter306

@MrSaLTy

@RocketBrewer

I am splitting this into four posts:

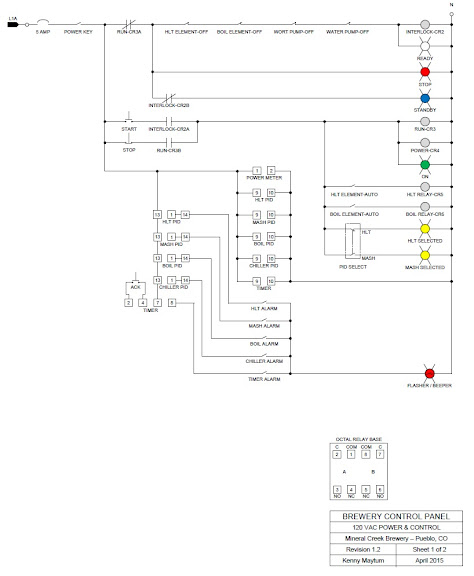

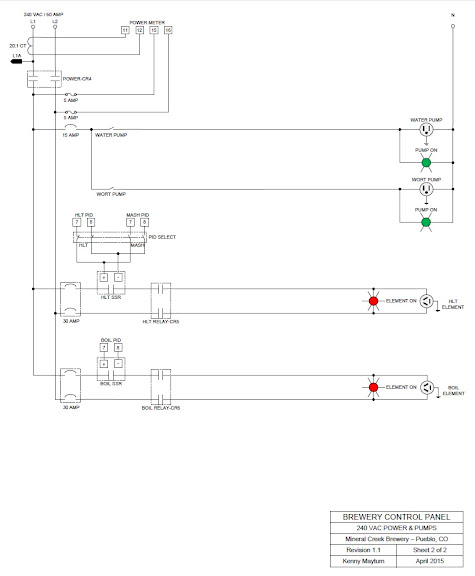

Post 1 - Introduction

Post 2 - Brewery room build

Post 3 - Equipment build and installation

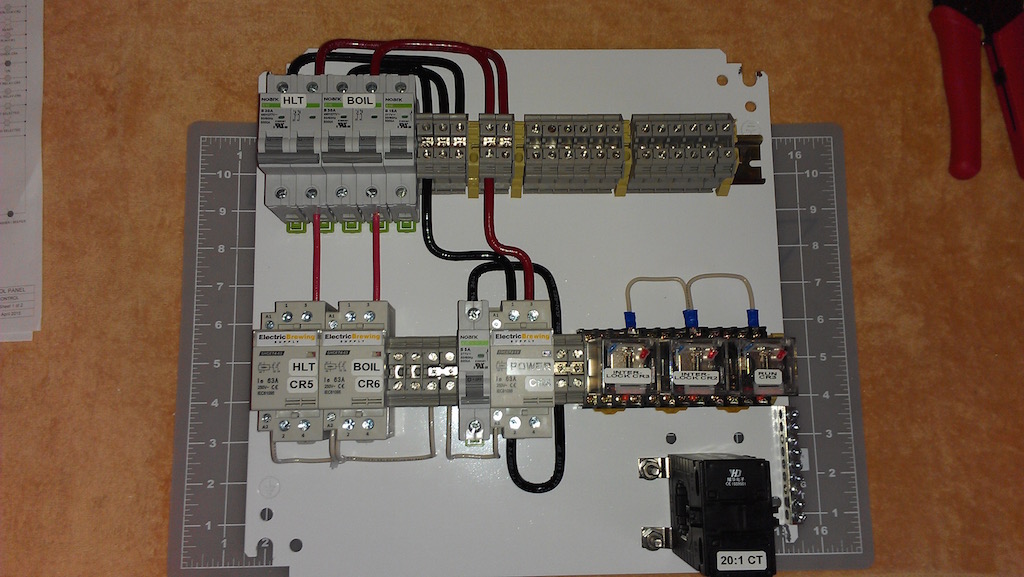

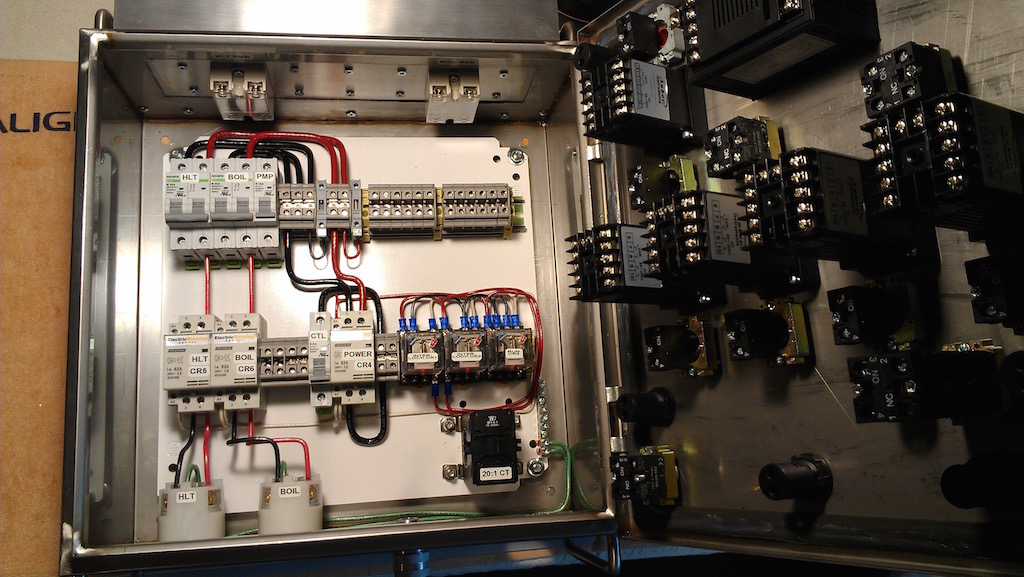

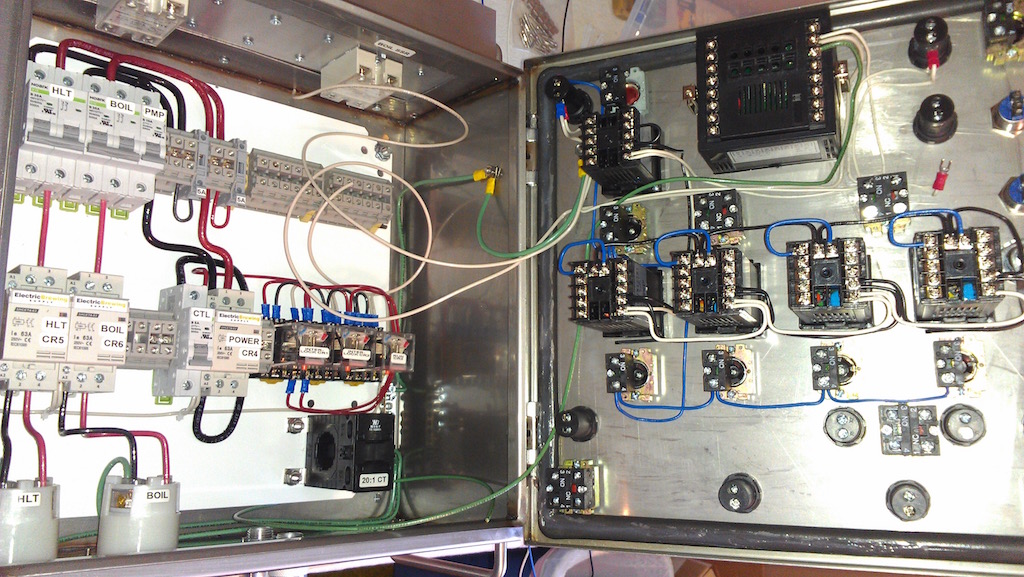

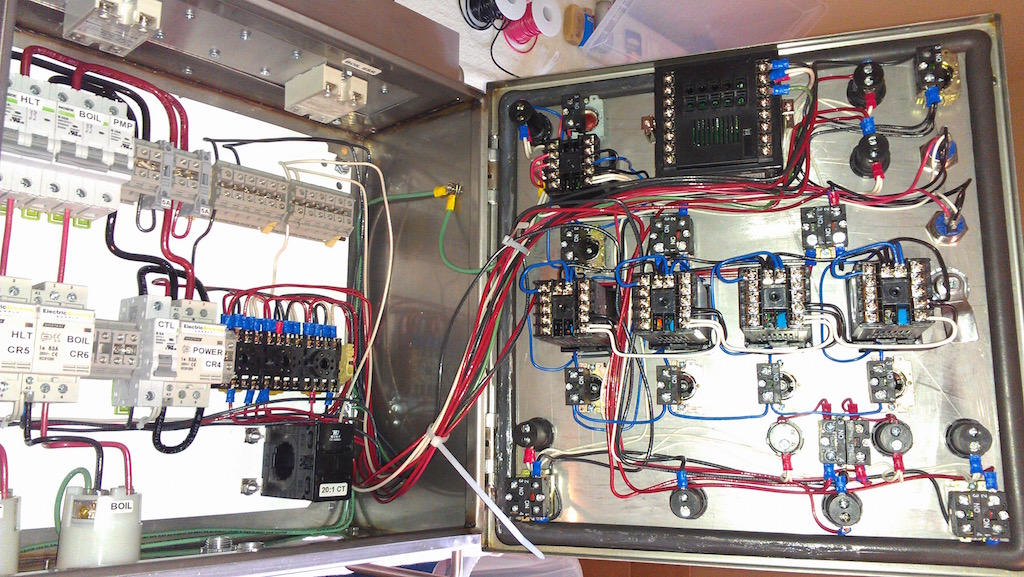

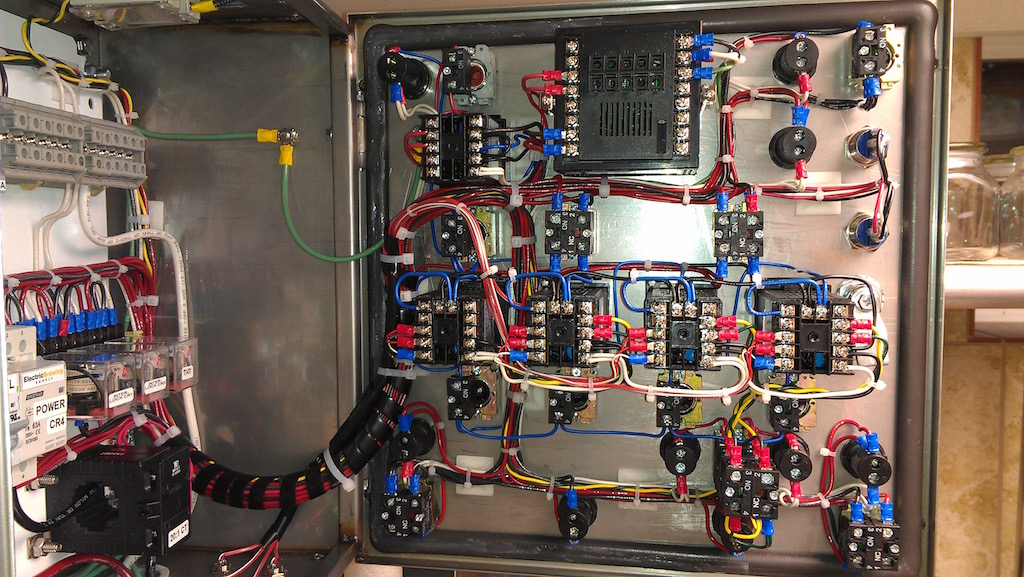

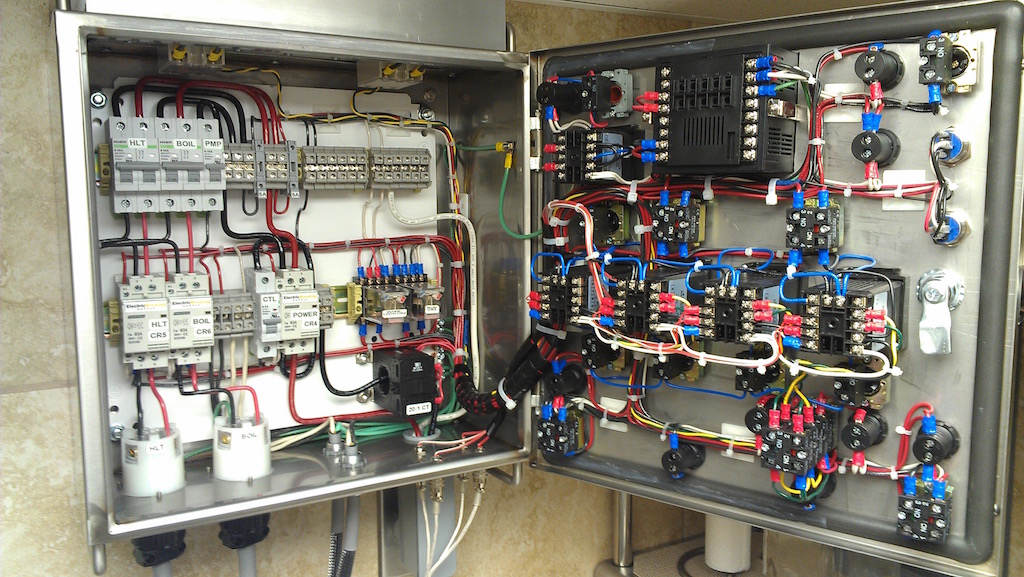

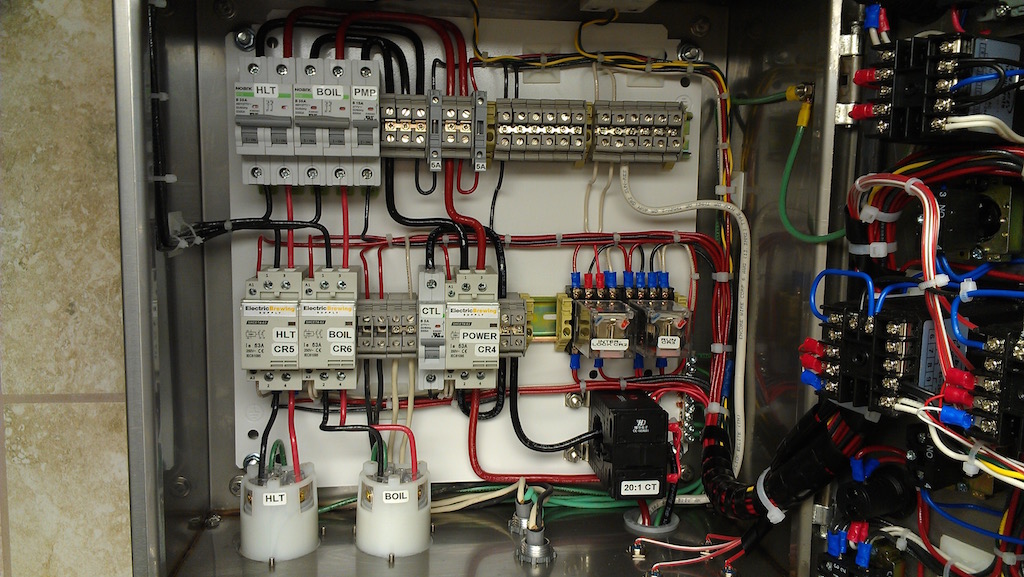

Post 4 - Control panel build and finished brewery

For those that want to see all of the photos of this build (almost 400), click here.

Thanks everyone!

KennyM

Mineral Creek Brewery

Pueblo, Colorado

I am a retired electronic systems engineer and started brewing after I took an early retirement in February 2014. I've always been curious about how brewing beer works but never had the time to invest in it. I started with extract kits and soon realized that all-grain was the way to go.

I started planning the brewery in September 2014 and began acquiring parts soon after that. Construction started in January 2015 and is pretty much complete as of June 2015. I am fortunate to have a very supportive SWMBO and the time and resources to devote to this project. I did all the work myself except for help with the ceramic tile which my son does for a living.

Thanks to everyone on these forums for all the terrific ideas, answers and solutions to problems you all have. I've learned so much following you all. Special thanks for some really good ideas and products goes out to the following folks as I used your products, ideas and inspiration...

Vendors:

http://www.auberins.com

http://www.brewershardware.com

http://www.brewhardware.com

http://www.ebrewsupply.com

http://www.stainlessbrewing.com

http://www.stilldragon.com

http://www.theelectricbrewery.com

http://www.zchillers.com

Forum Member Builds:

@azwillnj

@CptMidway

@Docbruw

@highland_brewer

@hunter306

@MrSaLTy

@RocketBrewer

I am splitting this into four posts:

Post 1 - Introduction

Post 2 - Brewery room build

Post 3 - Equipment build and installation

Post 4 - Control panel build and finished brewery

For those that want to see all of the photos of this build (almost 400), click here.

Thanks everyone!

KennyM

Mineral Creek Brewery

Pueblo, Colorado

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)