So after looking at other posts and blogs I think I might not be mashing correctly. My steps are as follows:

1. Preheat my round Igloo cooler

2. Mash in with water temp usually in the 160 range to give me my mash temps (determined by Beersmith). Stir well and make sure the temp in on point.

3. Mash for 60-90min depending on grain type

4. Start vorlaufing. Usually takes about 12-16 qts to get clear wort, then drain into brew kettle with a wide open valve. I get bubbles/foam in the kettle doing this.

5. Pour in sparge water which always seems to be 168 degrees according to Beersmith. Stir and wait for 15mins.

6. Vorlauf as I did for the mash. Drain with a wide open valve

Most of the time pre-boil gravity and volume are spot on and efficiency is around 75%

Here are my questions:

1. Is the bubbling wort into the kettle an issue? Hot side aeration? I have hear that is not really an issue with homebrewers, I don't have a stale flvor to my beer, but it would be easy to just buy a longer piece of tubing.

2. Should I be mashing out? Once again I have read some people say they do it and others that they don't. Will it help with mash ph or not extracting tannins?

Is the easiest way to just add boiling water and do I need to worry about the new water to grist ratio?

3. Should my sparge water be a high temp? It seems like I want my grain to be at 168 degrees and therefor my sparge water hotter?

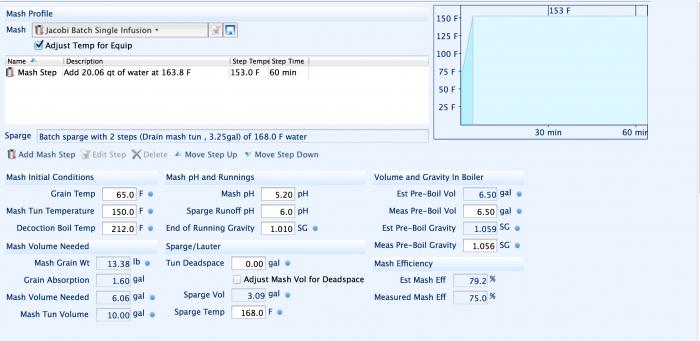

Here is a screen shot of one of my Beersmith recipes.

Thanks again,

Kevin

1. Preheat my round Igloo cooler

2. Mash in with water temp usually in the 160 range to give me my mash temps (determined by Beersmith). Stir well and make sure the temp in on point.

3. Mash for 60-90min depending on grain type

4. Start vorlaufing. Usually takes about 12-16 qts to get clear wort, then drain into brew kettle with a wide open valve. I get bubbles/foam in the kettle doing this.

5. Pour in sparge water which always seems to be 168 degrees according to Beersmith. Stir and wait for 15mins.

6. Vorlauf as I did for the mash. Drain with a wide open valve

Most of the time pre-boil gravity and volume are spot on and efficiency is around 75%

Here are my questions:

1. Is the bubbling wort into the kettle an issue? Hot side aeration? I have hear that is not really an issue with homebrewers, I don't have a stale flvor to my beer, but it would be easy to just buy a longer piece of tubing.

2. Should I be mashing out? Once again I have read some people say they do it and others that they don't. Will it help with mash ph or not extracting tannins?

Is the easiest way to just add boiling water and do I need to worry about the new water to grist ratio?

3. Should my sparge water be a high temp? It seems like I want my grain to be at 168 degrees and therefor my sparge water hotter?

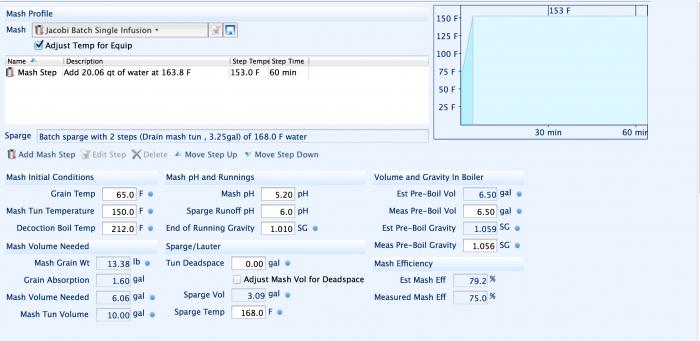

Here is a screen shot of one of my Beersmith recipes.

Thanks again,

Kevin