You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making Cider with 8 Different Yeasts - Which Should I Supersize to 5 Gallons?

- Thread starter Cogswell

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I've never used any of those yeasts.

My "goto yeast" is K1V-1116.

Good luck, please report back on what you used as far as juice, sugar, etc.. and how each turned out flavor wise.

My "goto yeast" is K1V-1116.

Good luck, please report back on what you used as far as juice, sugar, etc.. and how each turned out flavor wise.

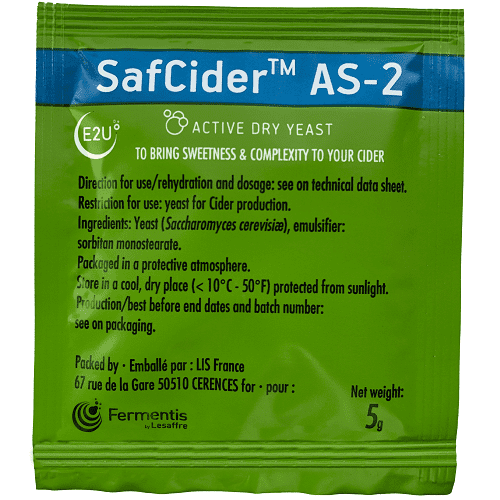

There was a big writeup on the SafCider ones in a recent Zymurgy. Led me to thinking I'd probably want to try AS-2 and TF-6 to see which I liked more. I've only made a couple of batches with US-05 and S-04, with the latter being preferred.

jseyfert3

Well-Known Member

Are you using fresh pressed or store bought filtered juice?

Cogswell

Well-Known Member

- Joined

- Sep 7, 2021

- Messages

- 67

- Reaction score

- 39

Are you using fresh pressed or store bought filtered juice?

Fresh pressed from an orchard.

Good luck, please report back on what you used as far as juice, sugar, etc.. and how each turned out flavor wise.

Thanks! Always planned to report my results. It's probably obvious but I'm doing this to figure out which yeasts I like best. All batches will be treated exactly the same to isolate yeast differences.

Here's the plan:

- Start with fresh pressed, unpasteurized, preservative free juice from an orchard

- Divide cider into sterilized fermenters

- Add campden tablets according to raw cider PH and install airlocks

- Wait twelve hours

- Add pectinase

- Wait twelve hours

- Add 1 gram of DAP per gallon

- Pitch yeast

- Wait for fermentation to complete

- Rack into CO2 purged secondary

- Wait until ???

- Maybe add campden tablets to stabilize???

- Transfer into CO2 purged kegs

- Refrigerate and force carbonate

- Drink!

Should I skip the secondary, go straight to keg and condition there?

Are the conditioning campden tablets unnecessary if I skip secondary and go straight to keg?

Should I add Sparkolloid or Super Kleer to the recipe?

Would Sparkolloid or Super Kleer inhibit my ability harvest yeast from the trub? $70 worth of yeast here. I'd like to bank as much as I can.

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

I have basically the same issue. First time making hard cider and wanted to play with a number of yeasts not necessarily knowing what I wanted as a final result(s).

I used a champagne yeast because I read people enjoyed the product.

To your selection:

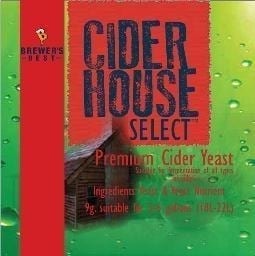

I used AB-1, AS-2, Cider House Select, and yesterday pitched TF-6.

We did gallon jugs for all except Cider House Select and TF-6 which are in 5 gal. buckets.

Sunday 10/3/21 we transferred into bottles (except obviously the TF-6, and the Cider House Select with is still perking) to get some carbonation into the product, but had to taste each prior to bottling.

My findings:

Champagne yeast: flat taste, and very dry. Incidentally, the dryness was a quality I "thought" I wanted, now seems too dry. Maybe the carbonation and some rest time will assist. I doubt it though.

AB-1 and AS-2; again, tasted flat, but not as dry.

So, that is why I pitched the TF-6 yesterday. The product description states it will bring out some of the fruitiness.

Originally I was attempting to stay away from the "fruitiness" as I find still cider too sweet, but after the few I've tested, I need some add'l taste. I'm sure many reading this will suggest adding a non- fermenting sweetener, such as apple juice concentrate, and depending on my final, final analysis, I may try that next year. Too late for this years attempt. As of this writing, and the yeasts noted and tasted above, all lack flavor. I would like to see the specific "cider yeasts" yet to be tested yield something closer to what I imagined (doesn't everyone,) some distinctive tastes.

Lastly, many in this forum have written of the merits of English ale yeasts for cider, so considering my less than great results to date, I will follow the suggested leads and next year try some cider made with a Nottingham ale yeast.

To conclude: without the results being final, I can only suggest your first go around using the specific cider yeasts; being an optimist (I make a point of keeping my glass more than half full, goes down to less, I fill it up again,) something makes me want to think the Cider House Select is going to work.

I used a champagne yeast because I read people enjoyed the product.

To your selection:

I used AB-1, AS-2, Cider House Select, and yesterday pitched TF-6.

We did gallon jugs for all except Cider House Select and TF-6 which are in 5 gal. buckets.

Sunday 10/3/21 we transferred into bottles (except obviously the TF-6, and the Cider House Select with is still perking) to get some carbonation into the product, but had to taste each prior to bottling.

My findings:

Champagne yeast: flat taste, and very dry. Incidentally, the dryness was a quality I "thought" I wanted, now seems too dry. Maybe the carbonation and some rest time will assist. I doubt it though.

AB-1 and AS-2; again, tasted flat, but not as dry.

So, that is why I pitched the TF-6 yesterday. The product description states it will bring out some of the fruitiness.

Originally I was attempting to stay away from the "fruitiness" as I find still cider too sweet, but after the few I've tested, I need some add'l taste. I'm sure many reading this will suggest adding a non- fermenting sweetener, such as apple juice concentrate, and depending on my final, final analysis, I may try that next year. Too late for this years attempt. As of this writing, and the yeasts noted and tasted above, all lack flavor. I would like to see the specific "cider yeasts" yet to be tested yield something closer to what I imagined (doesn't everyone,) some distinctive tastes.

Lastly, many in this forum have written of the merits of English ale yeasts for cider, so considering my less than great results to date, I will follow the suggested leads and next year try some cider made with a Nottingham ale yeast.

To conclude: without the results being final, I can only suggest your first go around using the specific cider yeasts; being an optimist (I make a point of keeping my glass more than half full, goes down to less, I fill it up again,) something makes me want to think the Cider House Select is going to work.

Very limited cider experience here. I tried juice from an orchard once. The only one of those yeasts I ever used was White Labs English Cider. It makes a bit of a tart cider, which I think English cider is supposed to be.

I kegged mine and did not use any sorbate, stabilizers, etc. I only made 3 gallons. It did not get drank quickly and went “off” after maybe 6-8 weeks. The juice tasted really good, I would have been better off drinking the apple juice. I even tried freeze concentrating what was left to make some apple jack. The result was just awful.

It looks like you are planning to make 32 gallons of cider - which I can’t imagine is going to get drank quickly unless you are planning to hand it all out at a festival or something. So I would consider some kind of stabilization. I know wine makers use sulfites. Potassium Metabisulfite. Campden is sodium metabisufite. I’m not a chemist to know the difference. If you plan to bottle and carbonate I’m not sure how that works, though.

I kegged mine and did not use any sorbate, stabilizers, etc. I only made 3 gallons. It did not get drank quickly and went “off” after maybe 6-8 weeks. The juice tasted really good, I would have been better off drinking the apple juice. I even tried freeze concentrating what was left to make some apple jack. The result was just awful.

It looks like you are planning to make 32 gallons of cider - which I can’t imagine is going to get drank quickly unless you are planning to hand it all out at a festival or something. So I would consider some kind of stabilization. I know wine makers use sulfites. Potassium Metabisulfite. Campden is sodium metabisufite. I’m not a chemist to know the difference. If you plan to bottle and carbonate I’m not sure how that works, though.

Last edited:

RolandD

Well-Known Member

- Joined

- Aug 24, 2020

- Messages

- 143

- Reaction score

- 97

... I'm sure many reading this will suggest adding a non- fermenting sweetener, such as apple juice concentrate, and depending on my final, final analysis, I may try that next year. ...

Apple Juice concentrate is NOT an non-fermentable sugar. You will need to stabilize with potassium metabisulfite and potassium sorbate, otherwise the yeast will restart fermentation.

Lalvin D-47 has been my preferred cider yeast for the past year, but I'm very pleased with how Lavin K1-V1116 did on my last batch and may switch over to it.

jseyfert3

Well-Known Member

Ah. I ask because while I've only made cider from store bought filtered juice to date, of the yeasts you've listed I've used M02 and Safcider (when it was just Safcider without the different varieties. I liked D47 better than either of them, and wasn't particularly happy with the M02 in particular. And best part is D47 is dirt cheap compared to the "special" cider yeasts...Fresh pressed from an orchard.

They may be better with fresh juice though, which is why I asked. And certainly different fermentation temps may help tremendously (I ferment in my basement between 60-65 °F currently, though I'm working on getting a fermentation chamber set up).

RolandD, my mistake. Thank you for setting it straight. I had readily discounted the approach of adding, and would have gone back to study in depth prior to having attempted. I was aware that it required some form of stabilization and was remiss in not making note. However, since we have each other, have you indeed added an apple concentrate? If so, your findings and suggestions based on my earlier, albeit incorrect reply. Thank you for your correction wouldn't have liked to have been the blame for bad info.

Golddiggie

Well-Known Member

I've been using the Wyeast sweet mead yeast in my cider batches so far (three, two last season and one fermenting now). The yeast will not go to dry, leaving 2-3% sugar in the cider (or mead if you use it for that). To date, the batches produced with this yeast have been very well received. If you've not tried the yeast, I highly recommend doing so. Unless you want ALL the batches to go to dry.

BTW, I've not move any of the cider batches to another fermenter/vessel unless it was a keg (to carbonate the batches last season). Now that I'm using conical fermenters, I'll leave it there (dropping the yeast when it's time) and force carbonate in fermenter. It will then go direct into 500ml cans.

BTW, I've not move any of the cider batches to another fermenter/vessel unless it was a keg (to carbonate the batches last season). Now that I'm using conical fermenters, I'll leave it there (dropping the yeast when it's time) and force carbonate in fermenter. It will then go direct into 500ml cans.

You can add your pectinase along w campden. No need to wait.Fresh pressed from an orchard.

Thanks! Always planned to report my results. It's probably obvious but I'm doing this to figure out which yeasts I like best. All batches will be treated exactly the same to isolate yeast differences.

Here's the plan:

This is my first venture into cider so I'm open to suggestions. Honestly, I need advice on everything after step 9.

- Start with fresh pressed, unpasteurized, preservative free juice from an orchard

- Divide cider into sterilized fermenters

- Add campden tablets according to raw cider PH and install airlocks

- Wait twelve hours

- Add pectinase

- Wait twelve hours

- Add 1 gram of DAP per gallon

- Pitch yeast

- Wait for fermentation to complete

- Rack into CO2 purged secondary

- Wait until ???

- Maybe add campden tablets to stabilize???

- Transfer into CO2 purged kegs

- Refrigerate and force carbonate

- Drink!

Should I skip the secondary, go straight to keg and condition there?

Are the conditioning campden tablets unnecessary if I skip secondary and go straight to keg?

Should I add Sparkolloid or Super Kleer to the recipe?

Would Sparkolloid or Super Kleer inhibit my ability harvest yeast from the trub? $70 worth of yeast here. I'd like to bank as much as I can.

I’ve never used a fining agent with cider (mead is a diff story) besides pectinase. With time, cider will drop clear. The one exception to this rule is when using an apple high in tannins, such as a bitter variety, and only when using in a high ratio. I’ve use bitters as high as 30% of recipe and they drop clear, only after a long secondary.

If you do plan on reusing yeast, make sure you are using nutrients during the initial fermentation. I’d also throw in a pinch along w the saved yeast slurry. I would also not save it as long as beer yeast (that fermented beer).

I (and I suspect, most others) will be interested in your longer term results. I only became aware of these new Fermentis yeasts a couple of months ago and am keen to try them next year (we are into Spring now, down here). So please, Cogsworth and Uncle Bob, let us know how it all goes.

You are probably aware of how these yeasts are supposed to behave, but here is an extract from a paper by Etienne Dorignac - Technical Manager, Fruit Fermentation at Fermentis.

Yeast strains may have a huge impact on cider profiles, not only in terms of fermentation performances and analytics but for sure also from a sensory perception standpoint. As such, they can be considered as a powerful tool to diversify the cider offer in the market and cidermakers can play with them to achieve their final product target. For this purpose, Fermentis focused its research on the selection of valuable strains dedicated for ciders. SafCider™ AB-1 (Apple Balanced) will suit for all types of balanced ciders even under difficult fermentation conditions. SafCider™ AS-2 (Apple Sweet) will bring to sweet and dry ciders complex aromatic profile between fresh and cooked fruits and a rounder mouthfeel. SafCider™ AC-4 (Apple Crisp) will be applied for highly fresh and crisp sweet or dry ciders. SafCider™ TF-6 (Tutti Fruiti) will be dedicated to intensely fruity but rather sweet and round ciders.

Uncle Bob... I find that even my "favourite" yeasts (S04 and M02) don't seem to generate much flavour initially and the cider can be a little harsh, but what a difference a few months make... six months is even better. So, don't be too disappointed at this stage.

Also, for sweetness I sometimes monitor the cider taste during fermentation once it gets below 1.020 or so as this lets me know what percent sugar (or g/L) that I would like to end up with. This gives me an idea of where to stop fermentation (or back sweeten) although I know from experience that something like 25 g/L is the "sweet spot" for my carbonated cider (no pun intended!) and about half that for "dry". I tend to bottle just before this point then use heat pasteurisation to stop fermentation when a slight carbonation (1 -2 vols of CO2) has developed. Of course, kegging or chemical pasteurisation works also.

You are probably aware of how these yeasts are supposed to behave, but here is an extract from a paper by Etienne Dorignac - Technical Manager, Fruit Fermentation at Fermentis.

Yeast strains may have a huge impact on cider profiles, not only in terms of fermentation performances and analytics but for sure also from a sensory perception standpoint. As such, they can be considered as a powerful tool to diversify the cider offer in the market and cidermakers can play with them to achieve their final product target. For this purpose, Fermentis focused its research on the selection of valuable strains dedicated for ciders. SafCider™ AB-1 (Apple Balanced) will suit for all types of balanced ciders even under difficult fermentation conditions. SafCider™ AS-2 (Apple Sweet) will bring to sweet and dry ciders complex aromatic profile between fresh and cooked fruits and a rounder mouthfeel. SafCider™ AC-4 (Apple Crisp) will be applied for highly fresh and crisp sweet or dry ciders. SafCider™ TF-6 (Tutti Fruiti) will be dedicated to intensely fruity but rather sweet and round ciders.

Uncle Bob... I find that even my "favourite" yeasts (S04 and M02) don't seem to generate much flavour initially and the cider can be a little harsh, but what a difference a few months make... six months is even better. So, don't be too disappointed at this stage.

Also, for sweetness I sometimes monitor the cider taste during fermentation once it gets below 1.020 or so as this lets me know what percent sugar (or g/L) that I would like to end up with. This gives me an idea of where to stop fermentation (or back sweeten) although I know from experience that something like 25 g/L is the "sweet spot" for my carbonated cider (no pun intended!) and about half that for "dry". I tend to bottle just before this point then use heat pasteurisation to stop fermentation when a slight carbonation (1 -2 vols of CO2) has developed. Of course, kegging or chemical pasteurisation works also.

I have never used any of those yeasts, although MJ's M02 is on my list of yeasts to try. I generally use Red Star Côte des Blanc yeast; and when I bottle it I dump more apple juice and a cup of sugar on the yeast cake.

Voss Kveik yeast (OYL-061) works very well for cider too and it's *fast*, but sometimes doesn't carbonate well. I also want to try German Ale yeast K-97. A typical batch for me is 3.5 or 4 gallons because I have a bunch of 4 gallon plastic carboys.

Voss Kveik yeast (OYL-061) works very well for cider too and it's *fast*, but sometimes doesn't carbonate well. I also want to try German Ale yeast K-97. A typical batch for me is 3.5 or 4 gallons because I have a bunch of 4 gallon plastic carboys.

Chalkyt, very pleased to hear such input. Admittedly a bit bummed, but far from discouraged. Totally prepared to allow time to make me feel successful, and not past talking myself into thinking the product is great. (I will however only lie to myself, and some others that I have undoubtedly over served with some other libation (homemade or purchased) prior to testing my product, yet promise to be honest within the forum.) FYI, as I write this response, my wife is listening to her favorite Aussie, Gavin Webber, aka The Curd Nerd, as she is attempting to improve her home made goat cheeses (not perfect, but moving forward.) So between ourselves, we have some work to do or we'll die trying, (probably via food poisoning.) I'll look into the M02. At this moment, I sense that my method to stop fermentation will also be via heat. All too new, but I'm persistent to a fault.

I value your words of encouragement.

I value your words of encouragement.

I have basically the same issue. First time making hard cider and wanted to play with a number of yeasts not necessarily knowing what I wanted as a final result(s).

I used a champagne yeast because I read people enjoyed the product.

To your selection:

I used AB-1, AS-2, Cider House Select, and yesterday pitched TF-6.

We did gallon jugs for all except Cider House Select and TF-6 which are in 5 gal. buckets.

Sunday 10/3/21 we transferred into bottles (except obviously the TF-6, and the Cider House Select with is still perking) to get some carbonation into the product, but had to taste each prior to bottling.

My findings:

Champagne yeast: flat taste, and very dry. Incidentally, the dryness was a quality I "thought" I wanted, now seems too dry. Maybe the carbonation and some rest time will assist. I doubt it though.

AB-1 and AS-2; again, tasted flat, but not as dry.

So, that is why I pitched the TF-6 yesterday. The product description states it will bring out some of the fruitiness.

Originally I was attempting to stay away from the "fruitiness" as I find still cider too sweet, but after the few I've tested, I need some add'l taste. I'm sure many reading this will suggest adding a non- fermenting sweetener, such as apple juice concentrate, and depending on my final, final analysis, I may try that next year. Too late for this years attempt. As of this writing, and the yeasts noted and tasted above, all lack flavor. I would like to see the specific "cider yeasts" yet to be tested yield something closer to what I imagined (doesn't everyone,) some distinctive tastes.

Lastly, many in this forum have written of the merits of English ale yeasts for cider, so considering my less than great results to date, I will follow the suggested leads and next year try some cider made with a Nottingham ale yeast.

To conclude: without the results being final, I can only suggest your first go around using the specific cider yeasts; being an optimist (I make a point of keeping my glass more than half full, goes down to less, I fill it up again,) something makes me want to think the Cider House Select is going to work.

What exactly are you shooting for, or do you know yet?

I like dry cider, but if it's too dry it doesn't taste like anything. But it's amazing how little sugar it takes to bring the "apple!" back to it. The Cote des Blanc yeast I mentioned earlier ferments dry but it doesn't go beyond that. I like that cider without any added sweetener, especially if I age it for a few months in the bottles before I drink it.

Apple juice concentrate is not a non-fermentable sugar; lactose is, but it's not really sweet. You might try sucralose (Splenda) or a sugar alcohol like erythritol. You could add those during fermentation or at bottling time. Or forget about all that and let the cider go completely dry, then add a splash of simple syrup when you serve it.

Heat pasteurisation is pretty straightforward but does need some care to minimise the chance of bottle bombs (we have all had one at some time or other). These aren't a problem for still cider as you would pasteurise with the bottles unsealed, but sealed bottles (for carbonation) are another matter as you need to know what bottle pressure you are dealing with. It isn't too hard to keep the pressure during pasteurising below 100psi which is generally well below the pressure rating for most bottles.

I currently pasteurise with a 65C constant temperature waterbath with the bottles in the hot water for about 10 minutes. With carbonation at 2 vols of CO2, bottle pressure doesn't exceed 85psi.

Attached is a paper that I have sent to a few others which will give you some insight into what is involved. You should also read Pappers post at the top of the forum which is where my interest in heat pasteurising started.

I currently pasteurise with a 65C constant temperature waterbath with the bottles in the hot water for about 10 minutes. With carbonation at 2 vols of CO2, bottle pressure doesn't exceed 85psi.

Attached is a paper that I have sent to a few others which will give you some insight into what is involved. You should also read Pappers post at the top of the forum which is where my interest in heat pasteurising started.

Attachments

RolandD

Well-Known Member

- Joined

- Aug 24, 2020

- Messages

- 143

- Reaction score

- 97

RolandD, my mistake. Thank you for setting it straight. I had readily discounted the approach of adding, and would have gone back to study in depth prior to having attempted. I was aware that it required some form of stabilization and was remiss in not making note. However, since we have each other, have you indeed added an apple concentrate? If so, your findings and suggestions based on my earlier, albeit incorrect reply. Thank you for your correction wouldn't have liked to have been the blame for bad info.

Apologies if that came off harsh. I was concerned you might have potential bottle bombs and get hurt.

For some ciders, I use four cans of a complementary frozen juice concentrate for a five gallon keg. That puts it in the range that my wife and I enjoy.

madscientist451

Well-Known Member

Years ago, I did many taste tests with different wine/beer and cider yeasts and juice combinations and came to the conclusion that the variety of apples used and their degree of ripeness is way more important than what yeast is used. Just because you are using fresh pressed orchard juice doesn't mean that your fermented cider will be all that great. Also keep in mind that many commercial juice producers water down their juice, and the apples used may not be ripe when processed. If you can find tree ripened fruit, carefully select the varieties and how much of each, sweat the apples for a month and make cider out of that, you'll see the difference I'm talking about. So if your apple blend isn't really suited to making good hard cider, don't expect the yeast to make up for that.

But back to the yeast, Cider House Select is my first choice when my LHBS has it in stock. I've used the White Labs yeast and it was just OK.

I've used various Beer Yeasts and most are ok and most wine yeasts make a very dry cider. 71-B wine yeast is a good choice if you are using the standard eating apples that most growers sell these days. So I've only used 2 out if the 8 choices above. My 2 cents: make a gallon batch of each and see which one you like the best before making a 5 gallon batch of anything. I've also noticed that juice from apples that ripen later in the season makes better hard cider so find out when your juice source stops making it and go back at the end and get some more.

But back to the yeast, Cider House Select is my first choice when my LHBS has it in stock. I've used the White Labs yeast and it was just OK.

I've used various Beer Yeasts and most are ok and most wine yeasts make a very dry cider. 71-B wine yeast is a good choice if you are using the standard eating apples that most growers sell these days. So I've only used 2 out if the 8 choices above. My 2 cents: make a gallon batch of each and see which one you like the best before making a 5 gallon batch of anything. I've also noticed that juice from apples that ripen later in the season makes better hard cider so find out when your juice source stops making it and go back at the end and get some more.

madscientist451, your point(s) are noted. I grow a nice combination of both cider and eating apples, the ratio of each, let alone varieties within each was mostly ignored this go around. I will however note that as the growing season winds down I am finding not only more juice when pressed, but more flavorful. My first pressing tastes different than my fourth, and I have one more pressing to go however, the variety is dwindling as some trees are more mature and yielded more fruit than others, the younger tree's fruit has already been used in prior pressings. In short, a rookie mistake but being new to the game I'm playing around to try and locate where I want to position myself, then I'll attempt to achieve. To date, I'm pretty sure that in the future I'll shy away from the drier tastes, which incidentally I though was something I would have liked. I look forward to the results of my labors, learning from my mistakes, but most of all, I enjoy the process and the science behind reaching a "goal."

Tancred the Brewer

Brewing Irony

- Joined

- Sep 19, 2019

- Messages

- 72

- Reaction score

- 77

There are so many factors that go into making great tasting cider, not least of which is personal taste. Each of us has a different taste preference which will impact how we perceive and/or enjoy the cider. I typically use 71B in a mix of ciders from my local orchard. They have a standard cider which is a mix of apples they have to get rid of, but generally always follows a formula for sweetness, bitterness and tartness, so is generally pretty similar no matter when you get it. But they also make a single varietal cider using only Goldrush apples. I have experimented and find that I prefer a 60/40 mix of their regular cider and their Goldrush cider. It gives me a nice tartness and flavor once fermented. I would agree with those above who state that the later in the year the cider is pressed the better the flavor, and in my experience the higher the sugar content. The standard cider usually starts around 1.060 but I bought some in March, which was their last press of the previous year's harvest and it came in closer to 1.080, as the apples had been sweating for close to 4 months at that point. I would also agree that the longer the cider sits the better the flavor gets. I have started drinking cider at 2 months and didn't really like the flavor profile. But with age it can really come into it's own. My current keg started fermenting in January and was kegged in September. It was quite good right out of the gate but has even improved with time in the fridge. I would suggest you set up a standard test using the same must and the various different yeasts you want to try. Let them go for 6-9 months and then do a sample tasting, without adding sugar. Then add a little sweetener to each in glass and retest. This will help you figure out the combination of must, yeast and sweetner level that best matches your taste preferences. Nothing is stopping you from fermenting the rest of the juice you have and enjoying it as you go, but doing the test this way now will help you to maximize future production.

Consigliere

Well-Known Member

- Joined

- Sep 16, 2020

- Messages

- 55

- Reaction score

- 28

Maybe a hijack here but has anyone ever used lactose and/or monk fruit sugar to back sweeten? I am also in process of first batch of cider (S04 ferment) and was hoping to keg and use unfermentable sweetener to avoid the whole halting yeast step.

Kees

Well-Known Member

I know none of these yeasts: would be very interested in your results. Whatever you do: make sure you use the same juice for all yeasts to keep things comparable.

I am seriously considering getting some erythritol to play with. I have some crabapple syrup that I made last year that I sometimes add to my glass of cider, but for the most part I like them dry as long as they are not so dry all the taste disappears.Maybe a hijack here but has anyone ever used lactose and/or monk fruit sugar to back sweeten? I am also in process of first batch of cider (S04 ferment) and was hoping to keg and use unfermentable sweetener to avoid the whole halting yeast step.

One good thing about using simple syrup or apple juice concentrate to sweeten is each of your guests can sweeten however much she wants and you don't make the whole batch too sweet for those who like it dry. This should work really well with kegging. Just put a squeeze bottle of syrup next to the tap and tell ppl what it's for.

Cogswell

Well-Known Member

- Joined

- Sep 7, 2021

- Messages

- 67

- Reaction score

- 39

Thanks everyone. So much useful information posted so far.

That scares the crap out of me considering the amount of cider I'm doing. Is that outcome common when kegging? I don't have room to refrigerate all 32 gallons of kegged cider.

I was considering Potassium Sorbate when kegging as an insurance policy. Anyone use it?

I've seen multiple sources say that while you can add it with the campden, it's more effective 12 hours after. Something about the sulfites inhibiting the action of the pectinase. Keep in mind I'm blindly repeating what I've read. I'm a clueless first timer.

Is DAP enough or do you recommend a more complex nutrient? If so do you have a favorite?

Unfortunately, it's too late for that.

Just a reminder, please vote in the poll if you've made yeast recommendations. It's much easier to reference than in-post recommendations. Thanks.

I kegged mine and did not use any sorbate, stabilizers, etc. I only made 3 gallons. It did not get drank quickly and went “off” after maybe 6-8 weeks.

That scares the crap out of me considering the amount of cider I'm doing. Is that outcome common when kegging? I don't have room to refrigerate all 32 gallons of kegged cider.

I was considering Potassium Sorbate when kegging as an insurance policy. Anyone use it?

You can add your pectinase along w campden. No need to wait.

I've seen multiple sources say that while you can add it with the campden, it's more effective 12 hours after. Something about the sulfites inhibiting the action of the pectinase. Keep in mind I'm blindly repeating what I've read. I'm a clueless first timer.

If you do plan on reusing yeast, make sure you are using nutrients during the initial fermentation. I’d also throw in a pinch along w the saved yeast slurry. I would also not save it as long as beer yeast (that fermented beer).

Is DAP enough or do you recommend a more complex nutrient? If so do you have a favorite?

My 2 cents: make a gallon batch of each and see which one you like the best before making a 5 gallon batch of anything. I've also noticed that juice from apples that ripen later in the season makes better hard cider so find out when your juice source stops making it and go back at the end and get some more.

Unfortunately, it's too late for that.

Just a reminder, please vote in the poll if you've made yeast recommendations. It's much easier to reference than in-post recommendations. Thanks.

Fleischmeister

Member

- Joined

- Jun 1, 2021

- Messages

- 11

- Reaction score

- 9

This is a great experiment! I recently did a similar test using 5 gallons of Aldi Apple juice, 1.5 pounds of sugar, and yeast nutrient. I used SA-05, SafCider AB-1, Cuvee Wine Yeast and CiderHouse. The SA-05 was sweet and had a nice sour apple flavor. I found the CiderHouse to be very similar. The Cuvee is drier but not as dry as I expected. It is still aging in the keg so I do need to sample it more. The AB-1 was my hands down favorite. The yeast produced some unique flavors that I can't pinpoint but are really nice. One friend described it as "the way a cider should taste". My non cider fans did not appreciate the AB-1.

Is DAP enough or do you recommend a more complex nutrient? If so do you have a favorite?

I’m a big fan of fermaid products. Last year when I pressed 50 gallons, I used both DAP and Fermaid O, at a 2:1 ratio.

If I were fermenting smaller amounts, I would probably just use Fermaid K.

As far as I know, K has DAP, whereas O does not.

I tend to be light handed when it comes to nutes. It really depends on your yeast and apples though. Most yeast will state nitrogen demands. IME, sharps require a lot more nitrogen.

I know this isn’t exactly scientific but let your sniffer tell you what the cider needs.

As far as pectinase, you could be right but it’s always worked for me when I add it along w campden. It’s also easier for my small brain to remember.

Best of luck with your experiment. I can’t wait for updates. I’m pretty settled in my ways as far as yeast but I could be persuaded to play with other yeasts in the name of science, of course.

I’m a big fan of fermaid products. Last year when I pressed 50 gallons, I used both DAP and Fermaid O, at a 2:1 ratio.

If I were fermenting smaller amounts, I would probably just use Fermaid K.

As far as I know, K has DAP, whereas O does not.

I tend to be light handed when it comes to nutes. It really depends on your yeast and apples though. Most yeast will state nitrogen demands. IME, sharps require a lot more nitrogen.

I know this isn’t exactly scientific but let your sniffer tell you what the cider needs.

As far as pectinase, you could be right but it’s always worked for me when I add it along w campden. It’s also easier for my small brain to remember.

Best of luck with your experiment. I can’t wait for updates. I’m pretty settled in my ways as far as yeast but I could be persuaded to play with other yeasts in the name of science, of course.

Cogswell

Well-Known Member

- Joined

- Sep 7, 2021

- Messages

- 67

- Reaction score

- 39

Update!

I decided to do 5 gallon and 2.5 gallon batches instead of 5 & 3 so I could squeeze out an additional 5 gallon batch.

5 Gallon Winners

Safcider TF-6, Safcider AC-4, Cider House Select, White Labs WLP775, Mangrove Jack M02, Wyeast 4766

2.5 Gallon Losers

Safcider AS-2, Safcider AB-1 - 2.5 gallons

Brought home 35 gallons of raw, unpasteurized cider. A few more gallons than expected.

Also purchased a gallon of drinking cider. It's significantly clearer than the raw cider. Both are delicious but the raw cider has more fruit flavor.

Buckets of cider are stored at a stable 68F.

PH is 3.76 to 3.78 depending on the bucket.

The cider is very cloudy. Can't see a brewing thermometer submerged 1".

Potassium metabisulfate is added to bring free SO2 to 150ppm.

24 hours later:

Pectic enzyme is added according to package instructions.

Another 24 hours later:

5.25g DAP and 10.5 Fermaid O is added to each bucket. (Each bucket contains 7 gallons of cider)

Each bucket is stirred vigorously to incorporate nutrients and outgas SO2.

Cider is divided from 7 gallon buckets to fermentation buckets. Cider is poured to maximize aeration and SO2 outgass.

Yeast is pitched into each fermentation bucket. Buckets are sealed with airlocks.

Dry yeasts were acclimated to cider temperature for 24 hours before pitching then pitched dry, no starter, by sprinkling on top of cider.

Wet yeasts were prepped according to directions, no additional starter, pitched by dumping on top of cider.

One packet of yeast was used regardless of batch size.

Five hours after pitching, AS-2 is going bananas. StarSan is foaming out of the airlock like a 90's foam party.

Stay tuned for a post primary fermentation report.

I decided to do 5 gallon and 2.5 gallon batches instead of 5 & 3 so I could squeeze out an additional 5 gallon batch.

5 Gallon Winners

Safcider TF-6, Safcider AC-4, Cider House Select, White Labs WLP775, Mangrove Jack M02, Wyeast 4766

2.5 Gallon Losers

Safcider AS-2, Safcider AB-1 - 2.5 gallons

Brought home 35 gallons of raw, unpasteurized cider. A few more gallons than expected.

Also purchased a gallon of drinking cider. It's significantly clearer than the raw cider. Both are delicious but the raw cider has more fruit flavor.

Buckets of cider are stored at a stable 68F.

PH is 3.76 to 3.78 depending on the bucket.

The cider is very cloudy. Can't see a brewing thermometer submerged 1".

Potassium metabisulfate is added to bring free SO2 to 150ppm.

24 hours later:

Pectic enzyme is added according to package instructions.

Another 24 hours later:

5.25g DAP and 10.5 Fermaid O is added to each bucket. (Each bucket contains 7 gallons of cider)

Each bucket is stirred vigorously to incorporate nutrients and outgas SO2.

Cider is divided from 7 gallon buckets to fermentation buckets. Cider is poured to maximize aeration and SO2 outgass.

Yeast is pitched into each fermentation bucket. Buckets are sealed with airlocks.

Dry yeasts were acclimated to cider temperature for 24 hours before pitching then pitched dry, no starter, by sprinkling on top of cider.

Wet yeasts were prepped according to directions, no additional starter, pitched by dumping on top of cider.

One packet of yeast was used regardless of batch size.

Five hours after pitching, AS-2 is going bananas. StarSan is foaming out of the airlock like a 90's foam party.

Stay tuned for a post primary fermentation report.