Hi all,

I noticed that the last couple batches of beer I made had lower than expected OG readings. Not sure what’s going on, could this be due to mash water temp? Too much water in the mash?

I still ended up with great tasting 5% (or above) beers but was aiming for closer to 6-7%. For example, my latest West Coast Pale had an OG of 1.052 but I was aiming for above 1.060. The beer seems to be fermenting as expected and there was no lag or anything after pitching yeast.

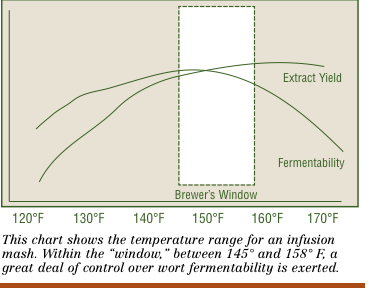

Had around 12.5lbs of grain, 0.5lbs dextrose, 5 gallons of mash water at 170f for 60mins (held at 162 as I wanted), then sparge with 3 gallons at 175.

Boiled for 60mins, cooled and transferred to fermentor. Pitched yeast and took my sample. Tasted and looked great!

Any advice or pointers would be helpful. I can provide more info if needed.

Thanks!

I noticed that the last couple batches of beer I made had lower than expected OG readings. Not sure what’s going on, could this be due to mash water temp? Too much water in the mash?

I still ended up with great tasting 5% (or above) beers but was aiming for closer to 6-7%. For example, my latest West Coast Pale had an OG of 1.052 but I was aiming for above 1.060. The beer seems to be fermenting as expected and there was no lag or anything after pitching yeast.

Had around 12.5lbs of grain, 0.5lbs dextrose, 5 gallons of mash water at 170f for 60mins (held at 162 as I wanted), then sparge with 3 gallons at 175.

Boiled for 60mins, cooled and transferred to fermentor. Pitched yeast and took my sample. Tasted and looked great!

Any advice or pointers would be helpful. I can provide more info if needed.

Thanks!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)