water to grist ratio X temperature X mash pH X time = mash efficiency. Go back over the formula; something is out of kilter. As far as the grist, it was always touted that the crush should reduce the average grain kernel to about 5 pieces. These days too many want to reduce the grain bill to powder. Everyone seems to want to look for their lost keys under the street light instead of where they dropped them.

I didn't offer that as a real mathematical formula. These are the components of a mash. Each has a major effect on the overall performance of the mashing. If you focus on what's important, many of your problems tend to vanish.

Yeah the formula is utter gibberish. There are real formulas for efficiency:

Conversion Efficiency = Wt of Extract Created in Mash / Wt of Potential Extract in Grain

Lauter Efficiency = Wt of Extract Collected in BK / Wt of Extract Created in Mash

Mash Efficiency = Wt of Extract Collected in BK / Wt of Potential Extract in Grain

Mash Efficiency = Conversion Efficiency * Lauter Efficiency (algebra from 1st 3 formulas)

Brewhouse Efficiency = Wt of Extract Collected in Fermenter / Wt of Potential Extract in Grain

Packaged Efficiency (or End-to-End Efficiency) = Wt of Extract in Packaged Beer / Wt of Potential Extract in Grain

Extract is all the dissolved components in the wort. Extract is about 90% sugars and dextrins, with the balance being mostly protein, and some other minor components.

Conversion of starch to sugar and dextrins is a two step process: gelatinization followed by hydrolysis. Hydrolysis is the breaking down of the long starch chains into dextrins and sugars. Hydrolysis is catalyzed by the enzymes (alpha and beta amylase, and limit dextrinase.) Gelatinization must occur before hydrolysis can occur, because hydrolysis requires that the end of the chain being hydrolyzed be surrounded by water (each bond broken requires one water molecule to react with the bond in order to break it.) Hydrolysis also requires an enzyme molecule to be in contact with the bond being broken, and since the enzymes are large protein molecules, they cannot penetrate into the dense un-gelatinized starch granule structure.

Gelatinization is slower than hydrolysis, and must happen first, so it is the step that controls the overall rate of conversion (i.e. the rate controlling step.) Rate of conversion is controlled by the rate of gelatinization.

Gelatinization starts at the surface of the grits and proceeds inward. The larger the grit, the longer it takes to fully gelatinize the grit. This is the reason that crush fineness is the most important factor in determining the time to complete gelatinization, and thus the time to complete conversion.

The rate of gelatinization is also temperature dependent - it occurs faster at higher temperatures. The rate of gelatinization at a particular temperature is affected by the internal structure of the starch granules. So, some starch granules require higher temps to gelatinize at a given rate than other starch granules. Since gelatinization is faster at higher temperatures, conversion is faster at higher temperatures.

So, smaller grits and higher temperatures lead to faster gelatinization completion, and thus faster conversion completion. There is a limit on raising the temperature to reduce the mash time because as the temps get higher the rates of enzyme denaturing also increase, and at high enough temperatures the enzymes denature faster than gelatinization can complete, and conversion stops.

Mash thickness has a small effect on rate of conversion, and thus required mash time for complete conversion.

Kai Troester has shown that thinner mashes convert slightly faster than thick mashes (more strike water is better.)

pH affects primarily the rate at which the enzymes cause hydrolysis, so as long as the pH is in a range that hydrolysis occurs faster than gelatinization, it doesn't really affect conversion efficiency. As state in a post above range is about 5.0 to 6.0 (5.2 to 5.8 would be a more conservative range.)

Edit: We do have a

data point now that demonstrates that in cases of excessively low pH, enzyme action (but not gelatinization) will be shut down almost completely. Unfortunately, there were no pH readings taken of the mash.

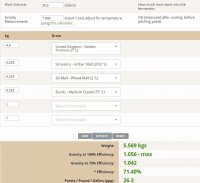

The net is that the time to get to 100% conversion is an interaction between gist size, mash temp, and mash time. No one has come up with a formula that predicts this (AFAIK.) It is possible to measure the percent conversion by measuring the SG of the wort in the mash. Turns out the SG at 100% conversion is a function of only grain bill weight, grain bill weighted potential, and strike water volume. So, to get complete conversion you can just mash until the SG in the mash is equal to the max possible SG (spreadsheet attached below.) You can approximate conversion efficiency by using either of the formulas below (the rigorous formula is a little more complicated, but the errors of the simplified formula are small when you are close to 100% conversion):

Conversion Efficiency = Measured °Plato / Max °Plato

Conversion Efficiency = (Measured SG - 1) / (Max SG -1)

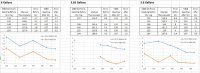

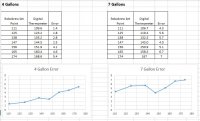

Lauter efficiency depends on the sparge process used. It's possible to accurately predict lauter efficiency for batch and no sparge (as long as the wort in the mash is thoroughly mixed prior to run off.) With batch sparging more sparge steps give higher efficiency, but each additional step provides a smaller increment of improvement vs. the previous sparge step (assuming a constant pre-boil volume - same amount of total brewing water.) Fly sparging, if done well, can give a slightly higher lauter efficiency than a triple batch sparge, but it is possible to get lower lauter efficiency if you have channeling during fly sparging. Accurately predicting fly sparge lauter efficiency requires solving differential equations whose parameters depend heavily on the specific equipment and process details, so hasn't been done for a homebrew situation (AFAIK.) Lauter efficiency for all methods decreases with increasing grain bill weight for a given pre-boil volume. Increasing pre-boil volume will compensate for larger grain bills, but then you have to boil off more water to reach a specific post-boil volume target.

As stated

above the difference between mash efficiency and brewhouse efficiency is all about volume left behind in the BK and any plumbing.

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)