1st shot at this NEM. Dubbel with OG at 1.024. I added 1/2lbs of d-90. Grain bill would normally be a 5-5.5%er. Calculations come out at 1.75% max. 4 weeks to report back.

Here's a report on how my two previously described attempts at cold mashed beers turned out:

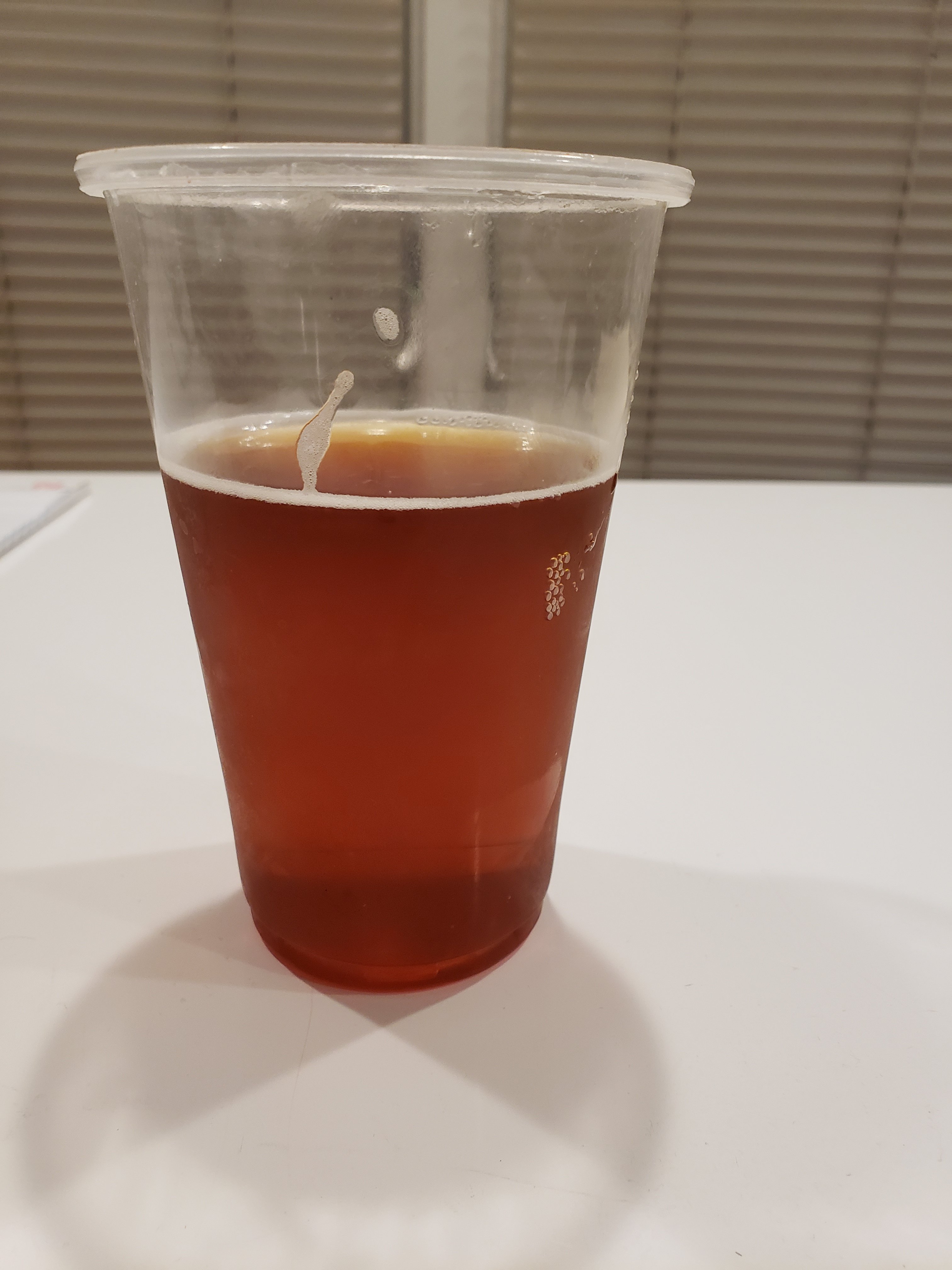

Attempt 1: LoMash Bitter. Finished at FG=1.009 for ABV=2.2%, calories=85 per 12 oz. Tastes like a reasonably flavorful session bitter. Looks like this:

View attachment 750727

Attempt 2: Belgian Helft. Finished at FG=1.006 for ABV=1.7%, calories=61 per 12 oz. Tastes pleasant, but with no "Belgian" character that I could detect. A bit thinner than the bitter, as one would expect. Looks like this:

View attachment 750728

Overall, I am pleased with the results and would call the experiment a success. However, it's a fair bit of extra time and work, and it consumes an excessive amount of grain relative to what you end up with. So as a control, I plan to do another experiment targeting a 2% beer with conventional mashing by simply scaling back the amount of grain. Will the resulting beer be noticeably thinner and less tasty? We'll see.

Yeah, that piqued my interest as well; i.e., using spent grains as a sort of "reverse parti-gyle". Since the bulk of the beta and alpha amylase are still in the grain bed, throw in your favorite mix of adjuncts that typically lack the diastatic power to self convert, along with a few handfuls of your favorite base grain, and do a traditional warm mash for a very flavorful low gravity wort. Two mashes for the price of one yielding two low alcohol (but full body and taste) beers. Win-win.@Brooothru : I haven't brewed with this technique for a couple of years (so no additional insights and no new links to additional quality articles elsewhere). At that point, my interests in the technique involved the "spent grains", not the wort.

My process is different from yours in that I did the cold mash for a few hours in a bag inside a 10 gallon cooler, lifted the bag and waited for suspended starch to settle out, then drained the wort into the boil pot. At this point, the wort was still quite cloudy. But to answer your question: Once I heated the pot to the conversion temperature of 150+ F and left it there a while, the wort became MUCH clearer, to the point that it looked to me like "normal" wort during the boil.It looks like the best profile for mashing is somewhere in the high 150s F to low 160s F to minimize beta amylase from converting too many starches to sugars while maximizing alpha amylase activity for body and mouthfeel. Is there clearing of the wort during mash? Most of the links I read mentioned that turbidity in the wort leads to scorching in the boil pot.

That might be a good method to try. I've got several Swiss voile bags left over from when I used to do BIAB. I could put a BIAB bag in the all-in-one, cold soak the grain for 8 hours, pull the bag, heat to 155-160F for an hour, then boil. Save the grains for a second mash with a few specialty grains. Done deal.I haven't done this for quite a while.

1. I now use a 400 micron brew in a bag bag. Once I started using that it didn't scorch. But I sure scorched the hell out of my fast batch pre-400 micron bag

2. I did several batches using the spent grains + 6-row. Came out fine but not a superlative beer. I should try an AK recipe with spent grains, 6-row, bit of corn, English hops and see how that goes

I keep checking in on this thread and prolly will take a few runs again in the summer. A saison might be nice as well.

As I understand it, heating the wort from room temp to a boil often results in a ~ 1% beer beer; while a rest at ~ 152* F results in a ~ 3% beer. When I used this technique I included the rest. Obviously the results will depend on the amount of sugars from the cold extraction step.but I am not sure the speed of direct heat is my friend in this situation

I have my first NEM mash, a Vienna Lager, in the fridge right now for a tomorrow AM brewday. I wanted a simple beer to judge the technique.

I milled 7# base grains, added my salts, Brewtan B, and acid, mashed in with room temp deaerated RO water, and placed the primary mash tun (a repurposed bucket fermenter) in a 32°F fridge for an overnight rest.

Tomorrow AM I will head back upstairs to the brewery, hoist the grain bag out of the primary and let it drain for an hour allowing the residual starches to settle below the spigot. Then, I’ll drain the initial mash wort into the secondary MLT for the ‘high mash’ (leaving the settled starches behind in the primary mash tun). I may transfer to the kettle, heat it, then transfer to the secondary MLT. The MLT heats via HERMS so the kettle would be faster but I am not sure the speed of direct heat is my friend in this situation. The slower indirect heat of the HERMS may be better in this situation. Decisions, decisions.

Either way, after the wort is at my target (172°F) I’ll add the .5# dark grains to the grain bag, place the bag in the secondary MLT to serve as a filter, and start the recirculation for the vorlauf/hot steep/‘high mash’.

I understand removing this settled residual starch is vital to success so I’ll vorlauf until clear. I am planning at least 30 min but it could be longer.

I’ll then xfer the — hopefully — clear, very low SG, but flavorful wort to the brew kettle and continue a routine brewday.

I’ll take some pH readings along the way. I have no idea if pH even matters in a mash that I don’t want enzymes to convert starch to sugars but we’ll see what they are anyway.

My goal is a full flavor, full mouthfeel, low carb beer. I don’t want a thin, watered down beer. I‘m sure this first run will need some future adjustments and I’m OK with that. We’ll see.

ref:

As I understand it, heating the wort from room temp to a boil often results in a ~ 1% beer beer; while a rest at ~ 152* F results in a ~ 3% beer. When I used this technique I included the rest. Obviously the results will depend on the amount of sugars from the cold extraction step.

focusing on the bolded phrases: With cold steeping (crystal malt, light roasted malts), over the past year, I did some short cold steeps, measuring OG and observing color changes. Grains were double crushed. I would shake/stir the malts ever 5 or 10 minutes. I found that OG was stable after about 30 minutes.I may alter my technique next time by mashing at room temp (or cooler) until I no longer see an increase in SG via regular sampling, recirculating the entire time, then transfer to the boil kettle and heat the wort quickly to a boil. On my next NEM, I will forgo the overnight refrigerated mash.

does this sound plausible?

Bummer. I too have been hoping for a magical elixir, or at least a process to make a low carb/ABV beer. I did brew a Brut IPA a while back with amyloglucosidaise that did well in a comp, but it tasted like a Mich Ultra. I’d hoped that cold mash low enzyme would be the silver bullet.Well, the taste test of the NEM Vienna Lager is less than stellar. It just tastes… weird. Kind of a soap flavor or something. I’m going to give it some more time but at this point it’s a dumper.

It makes me wonder if the juice is worth the squeeze. My goal remains low(er) carb, full flavor beer but I am concerned this may not be the path forward.

Of course, the possibility exists that I can improve on the process so I will try again, but I am at a crossroads right now. Second guessing myself. The best bet may be brew a small grain bill and/or use enzymes. IDK