Alan Reginato

Well-Known Member

I just saw this thread. I will save it, because I liked the idea. On winter, South hemisphere, I will give it a try. I shall share my perceptions.

Ok. I give it a try.

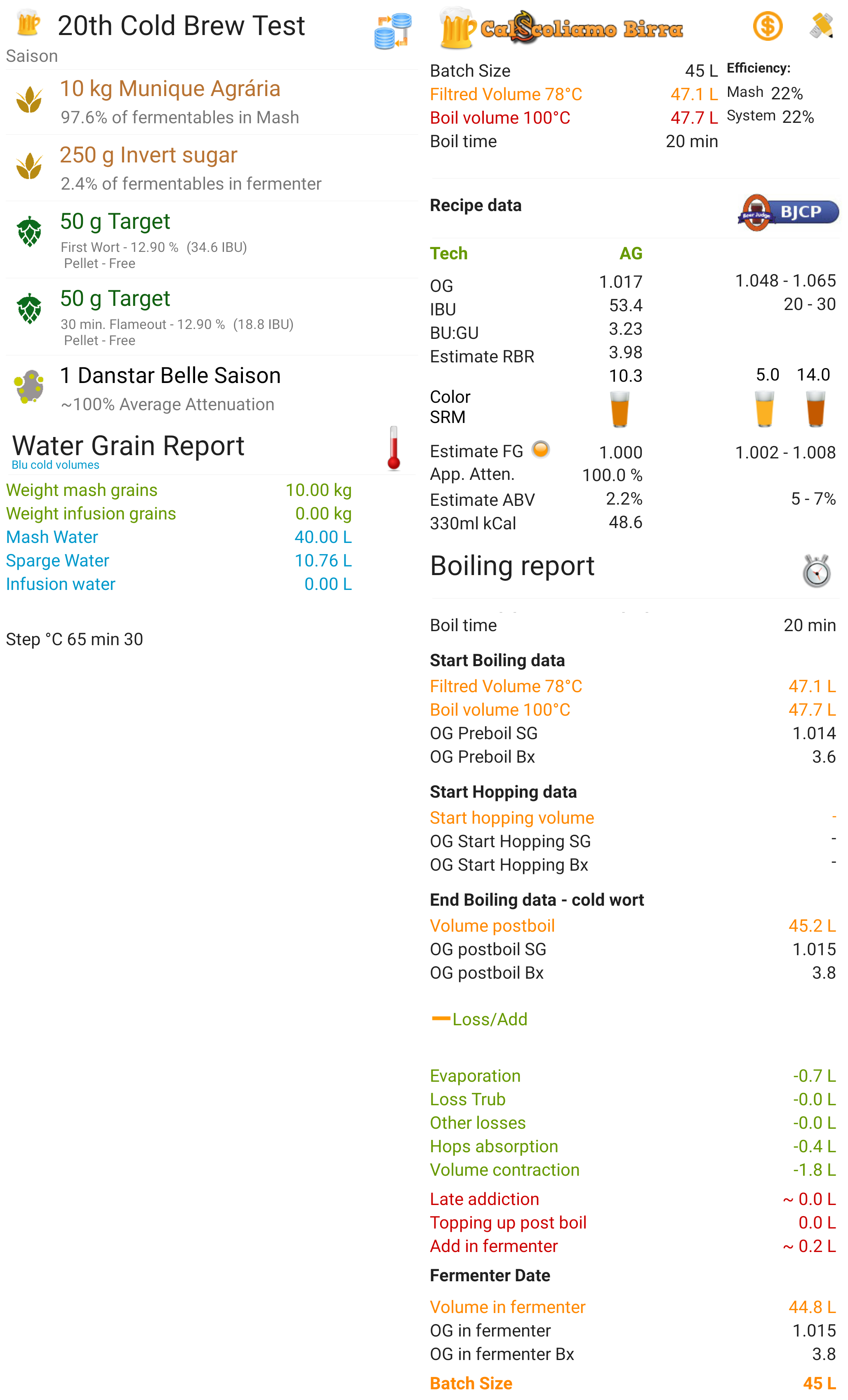

The recipe:

The inverted sugar would be the priming sugar.

I choose the 1 hour stirring approach. It was manual, so it was also a exercise. Not too hard, a medium speed was enough.

IMHO It worked, a lot of colour was extracted.

During the stirring process.

I asked a fine grind, to BIAB setup. So, a lot of malt flour comes too. And after liftoff the grain bag and do a sparge, when I turned on the electric element, it turned to be a nightmare. In less than 3 minutes I could smell something burning. Take off the element and the scorching was REALLY bad. Maybe a gas burner would work better. Anyway I cleaned it. Added 4 whirflocks. Waited for 4 hours, transferred the wort to the fermentors. Cleaned the kettle, there was a lot of insoluble starch in there. Transferred back, cleaned the fermentors, a lot of cleaning involved...

Them turned the heat on, again, when it went about 60C, burnt smell again, cleaning again, turn on again and did a 65C mash, for 1 hour.

The insoluble starch and the scorching are a HUGE PROBLEM, SERIOUSLY. Let it settle down and racking aren't optional.

After all, forgot to take other pictures. But everything went normal, it is fermenting now. No sinal of burnt flavours, or I hope it so.

The final colour was a deep red, very nice. And smelled good too. The yeast was from a stout, so the final result will be a little darker.

I shall update as it goes, wish me luck!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)