I've made a Baltic Porter recipe a few times, and I keep getting a low attenuation in the fermentation (the "Apparent Attenuation" that Brewfather calculates). I see it come through as higher than predicted FG. The recipe originated from a BEERMKR Kit. That's a whole other story, but I made the beer there first and it seemed delicious, but I couldn't get the built-in dispensing kit to work so I was only ever able to get one pint out of it. And the BEERMKR is not set up for taking any kind of measurements of gravity, so I have no idea what kind of numbers I got using this recipe in that machine.

I carried the recipe over to my AG setup and scaled it up from the 1-gal BEERMKR size. It attenuated poorly, and I blamed it on what seemed to be an extremely high amount of specialty grains. So I adjusted the recipe to add a dose of Brewer's Malt, but still got low attenuation. I then brewed a 3rd time, and pitched more yeast, thinking I had underpitched on the 2nd batch. But it came out the exact same. I've used this yeast before (Cellar Science Berlin) with great results in various lagers and gotten good attenuation (70+ %).

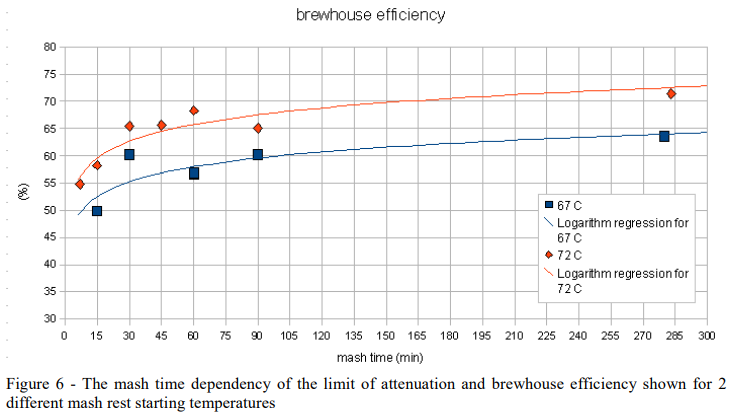

So I'm not sure if I've got something funky with the grain bill that's driving the attenuation, or maybe it's this yeast coupled with the higher mash temperature. The other batches where I've gotten 70+% attenuation have been mashed at 148F, and this Baltic Porter I was mashing at 154F. I know the higher temp will give me lower attenuation, but it seems like a big drop off to be at 55%. Here's the details:

Batch#241 Baltic Porter

Munich 33%

Vienna 33%

Carafa Special II 11%

Caramunich III 11%

Special B 11%

Mashed Munich and Vienna to the below schedule, then added Carafa, Caramunich, and Special B at Mash out

156F for 45 mins

168F for 10 mins

Measured mash pH 5.5 (20+ minutes in to mash, sample cooled to room temp before measurement)

1 pack Cellar Science Berlin (no starter, no re-hydrating)

52F for 4 days until Tilt showed rate of gravity change start to slow, then slowly raised temperature

OG 1.061 (low by 11 points, which is very uncommon for me)

FG 1.027 (high by 5 pts vs where Brewfather was predicting)

Apparent Attenuation 54.5%

Batch#272 Baltic Porter

Brewer's 2-row 32%

Munich 22%

Vienna 22%

Carafa Special II 8%

Caramunich III 8%

Special B 8%

Mashed Brewer's, Munich, and Vienna to the below schedule, then added Carafa, Caramunich, and Special B at Mash out

154F for 50 mins

168F for 10 mins

Measured mash pH 5.29 (20+ minutes in to mash, sample cooled to room temp before measurement)

1 pack Cellar Science Berlin (no starter, no re-hydrating)

55F for 4 days until Tilt showed rate of gravity change start to slow, then slowly raised temperature

OG 1.071 (low by 6 points, which is very uncommon for me)

FG 1.031 (high by 16 pts vs where Brewfather was predicting)

Apparent Attenuation 54.8%

Batch#276 Baltic Porter

Brewer's 2-row 32%

Munich 22%

Vienna 22%

Caramunich III 8%

Special B 8%

Carafa Special II 6%

Carafa Special III 2% (misplanned, ran out of Special II...)

Mashed Brewer's, Munich, and Vienna to the below schedule, then added Carafa, Caramunich, and Special B at Mash out

154F for 50 mins

168F for 10 mins

Measured mash pH 5.25 (20+ minutes in to mash, sample cooled to room temp before measurement)

2 packs Cellar Science Berlin (no starter, no re-hydrating)

55F for 4 days until Tilt showed rate of gravity change start to slow, then slowly raised temperature

OG 1.072 (low by 4 points, which is very uncommon for me)

FG 1.032 (high by 17 pts vs where Brewfather was predicting)

Apparent Attenuation 54%

I carried the recipe over to my AG setup and scaled it up from the 1-gal BEERMKR size. It attenuated poorly, and I blamed it on what seemed to be an extremely high amount of specialty grains. So I adjusted the recipe to add a dose of Brewer's Malt, but still got low attenuation. I then brewed a 3rd time, and pitched more yeast, thinking I had underpitched on the 2nd batch. But it came out the exact same. I've used this yeast before (Cellar Science Berlin) with great results in various lagers and gotten good attenuation (70+ %).

So I'm not sure if I've got something funky with the grain bill that's driving the attenuation, or maybe it's this yeast coupled with the higher mash temperature. The other batches where I've gotten 70+% attenuation have been mashed at 148F, and this Baltic Porter I was mashing at 154F. I know the higher temp will give me lower attenuation, but it seems like a big drop off to be at 55%. Here's the details:

Batch#241 Baltic Porter

Munich 33%

Vienna 33%

Carafa Special II 11%

Caramunich III 11%

Special B 11%

Mashed Munich and Vienna to the below schedule, then added Carafa, Caramunich, and Special B at Mash out

156F for 45 mins

168F for 10 mins

Measured mash pH 5.5 (20+ minutes in to mash, sample cooled to room temp before measurement)

1 pack Cellar Science Berlin (no starter, no re-hydrating)

52F for 4 days until Tilt showed rate of gravity change start to slow, then slowly raised temperature

OG 1.061 (low by 11 points, which is very uncommon for me)

FG 1.027 (high by 5 pts vs where Brewfather was predicting)

Apparent Attenuation 54.5%

Batch#272 Baltic Porter

Brewer's 2-row 32%

Munich 22%

Vienna 22%

Carafa Special II 8%

Caramunich III 8%

Special B 8%

Mashed Brewer's, Munich, and Vienna to the below schedule, then added Carafa, Caramunich, and Special B at Mash out

154F for 50 mins

168F for 10 mins

Measured mash pH 5.29 (20+ minutes in to mash, sample cooled to room temp before measurement)

1 pack Cellar Science Berlin (no starter, no re-hydrating)

55F for 4 days until Tilt showed rate of gravity change start to slow, then slowly raised temperature

OG 1.071 (low by 6 points, which is very uncommon for me)

FG 1.031 (high by 16 pts vs where Brewfather was predicting)

Apparent Attenuation 54.8%

Batch#276 Baltic Porter

Brewer's 2-row 32%

Munich 22%

Vienna 22%

Caramunich III 8%

Special B 8%

Carafa Special II 6%

Carafa Special III 2% (misplanned, ran out of Special II...)

Mashed Brewer's, Munich, and Vienna to the below schedule, then added Carafa, Caramunich, and Special B at Mash out

154F for 50 mins

168F for 10 mins

Measured mash pH 5.25 (20+ minutes in to mash, sample cooled to room temp before measurement)

2 packs Cellar Science Berlin (no starter, no re-hydrating)

55F for 4 days until Tilt showed rate of gravity change start to slow, then slowly raised temperature

OG 1.072 (low by 4 points, which is very uncommon for me)

FG 1.032 (high by 17 pts vs where Brewfather was predicting)

Apparent Attenuation 54%