Surly_goat

Hop Head

- Joined

- Feb 15, 2018

- Messages

- 76

- Reaction score

- 17

Hey Guys

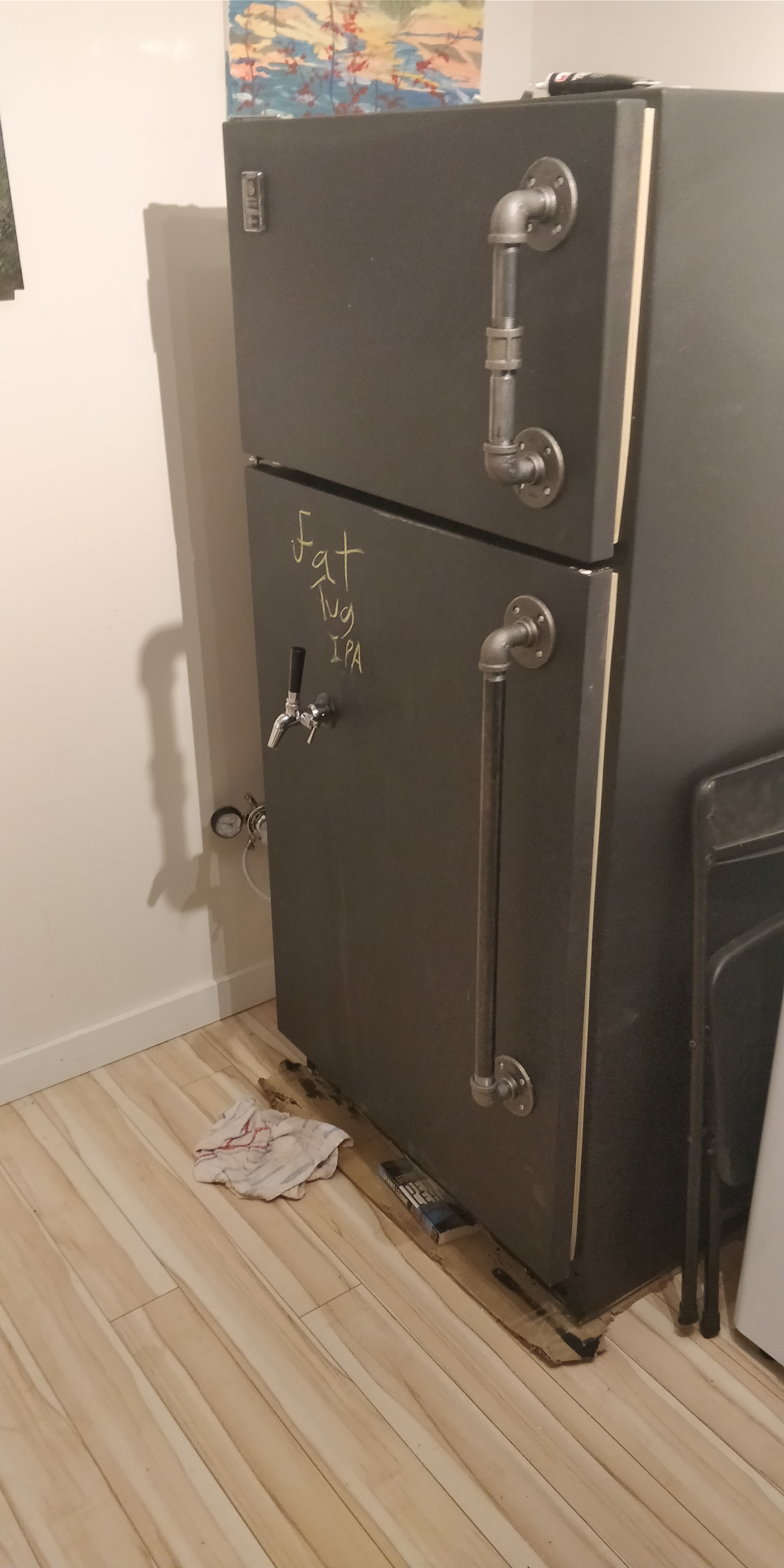

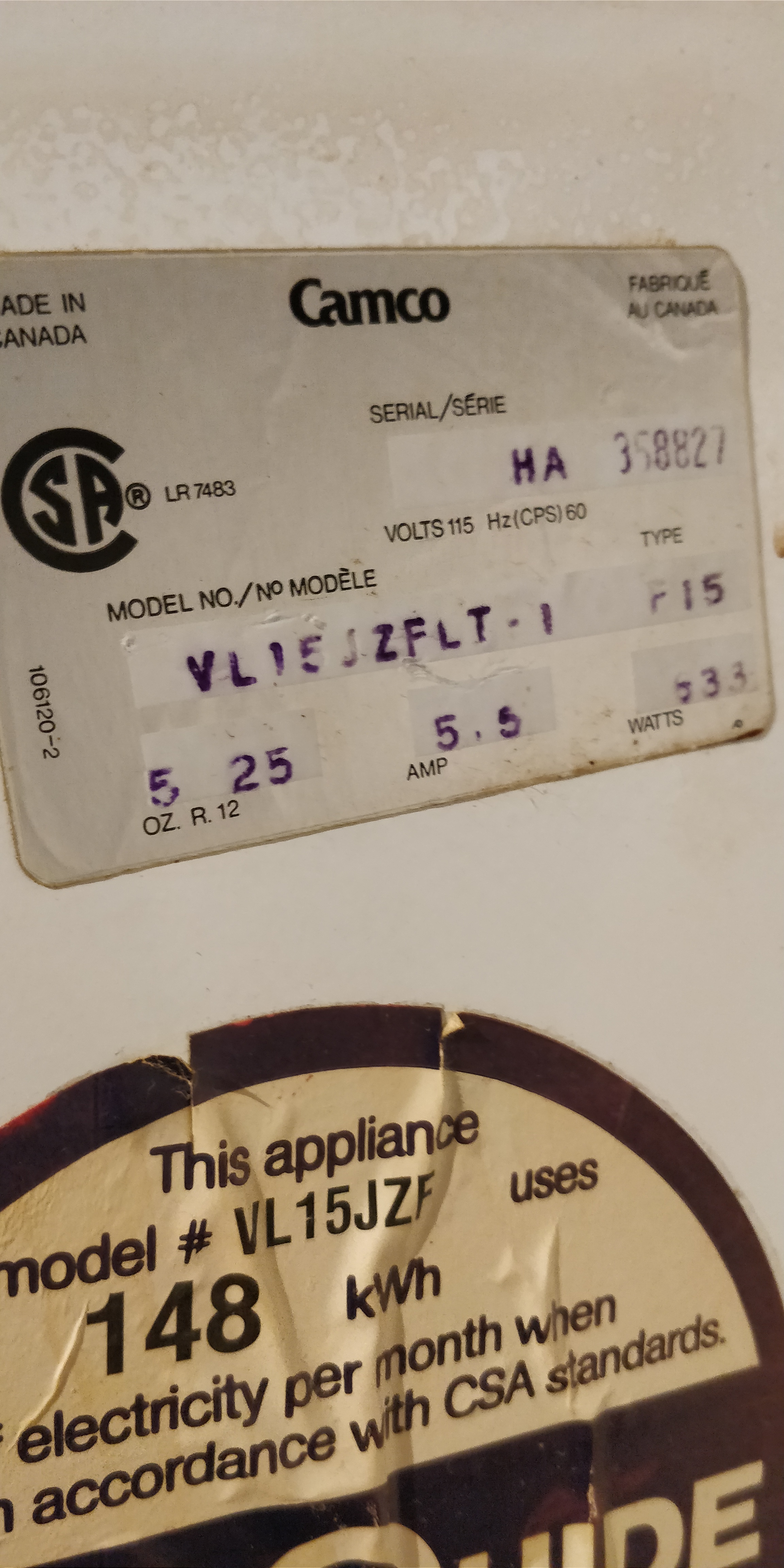

Hey GuysPicked up a free fridge on Craigslist and repainted it with chalkboard paint. I also took appart the doors and washes the gasket in hot PBW and then put them outside my balcony to dry and be out of the way. Its only like 6 celsius here right now so I think they dried warped. The door won't seal at all now. It's also not flat at all.

Ideas?

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)