- Joined

- Dec 14, 2015

- Messages

- 151

- Reaction score

- 15

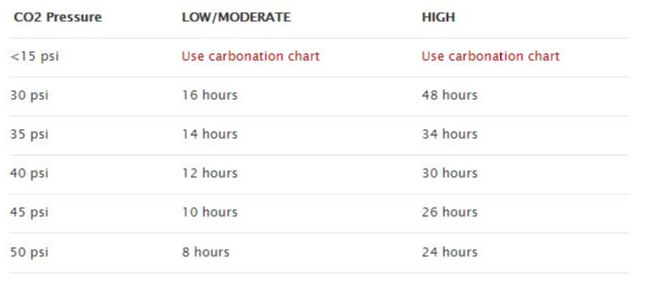

I’ve been reading about dry hopping in a keg warm under pressure. What I don’t understand is that many of these scenarios car for warm dry hop under pressure for five days of 30 psi. If I do 30 psi cold, then my beer is carbonated in a day. How is anyone successfully dry hopping warm in a keg or under pressure without carbonating their beer over this period of time?

trying to avoid over carbonated beer

trying to avoid over carbonated beer