If I am having trouble hitting my OG numbers, would mashing for a longer time, say 90 minutes instead of 60 help? I am thinking of tightening my crush as well. My current setup is at about credit card thickness, but thinking of going down a bit finer to see if that helps. I am just perusing different posts and it just hit me to ask. If it is a stupid question please say so, but I thought it might make sense and give it a try. Rock On!!!!!!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just got to thinking about mash times

- Thread starter redrocker652002

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I mash until I hit a particular gravity. Depending on your mash thickness, you should end up close to a certain gravity reading. Check out this chart.

For instance, I use a 1.44 qt/lb thickness and I usually end up at 1.082, which is ~95.5%. For large grain bills I use 1.33 qt/lb and I end up at 1.088.

For instance, I use a 1.44 qt/lb thickness and I usually end up at 1.082, which is ~95.5%. For large grain bills I use 1.33 qt/lb and I end up at 1.088.

Do the finer crush first. Then consider a longer mash if you aren't getting the OG you want. One caveat, finer crush may get you a stuck mash. Use rice hulls to help making a filter bed to avoid the stuck mash.

BrewnWKopperKat

(Ο_Ο)

·

Last edited:

More time can help get complete conversion, unless you are mashing at a hot enough temperature to denature the alpha amylase before the mash time runs out. Starch has to be gelatinized before the amylase can act on it to convert it to sugar. Once you have some of the starch gelatinized, conversion can start. Gelatinization and conversion then proceed in parallel until all gelatinization is complete. Then there is a short period after complete gelatinization during which amylase continues to break the carbohydrates down to smaller and smaller pieces, eventually stopping when all of the starch has been converted to monosaccharides (eg. glucose), disaccharides (eg. maltose), and limit dextrins (branched molecules that alpha amylase cannot break down.)

Larger grits take longer to completely gelatinize than smaller grits, so the mash takes longer to reach 100% conversion.

Brew on

Larger grits take longer to completely gelatinize than smaller grits, so the mash takes longer to reach 100% conversion.

Brew on

if you are already milling at credit card thickness I don't think any tighter will help.

But if you are only mashing 60 minutes, then yes, 90 might help out.

Most conversion happens in the first 20-30 minutes. But lingering starches take a while.

But you left out mash temps. What are you mashing in at? If too hot, the enzymes are gonna denature too soon. Once that happens it's game over.

But if you are only mashing 60 minutes, then yes, 90 might help out.

Most conversion happens in the first 20-30 minutes. But lingering starches take a while.

But you left out mash temps. What are you mashing in at? If too hot, the enzymes are gonna denature too soon. Once that happens it's game over.

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

My mash temps usually are between 150 and 155. I have to admit that a few times it has hit 160 for just a few minutes but was able to get it back down again. I am pretty sure my thermometer on my kettle is accurate as I checked it against my pen style and they both were the same in the water I had as my test.if you are already milling at credit card thickness I don't think any tighter will help.

But if you are only mashing 60 minutes, then yes, 90 might help out.

Most conversion happens in the first 20-30 minutes. But lingering starches take a while.

But you left out mash temps. What are you mashing in at? If too hot, the enzymes are gonna denature too soon. Once that happens it's game over.

I might go 90 and check it at about 50, 60 and 80 to see where I am.

Thanks to all who replied. I welcome any and all input.

hotbeer

Opinionated Newb

- Joined

- Mar 10, 2021

- Messages

- 3,090

- Reaction score

- 2,809

I'd be leery of just measuring the temperature at one point. I use an instant read pen type thermometer and stick the probe into my bag in different places and into the wort outside the bag in different places.

If you are doing a mash for five gallons or better, you might need a probe that's longer than the one on my pen type thermometer.

If you are doing a mash for five gallons or better, you might need a probe that's longer than the one on my pen type thermometer.

Are you sparging or doing a full volume BIAB style?

My method is mash for 60, first batch sparge, lauter for 15 minutes until clear, drain into kettle and then do a 2nd batch sparge for 15 minutes. I typically always hit my numbers or very close to it. I do not crush my own grains either

Elaborate on your mash process and you might get some more helpful tips.

My method is mash for 60, first batch sparge, lauter for 15 minutes until clear, drain into kettle and then do a 2nd batch sparge for 15 minutes. I typically always hit my numbers or very close to it. I do not crush my own grains either

Elaborate on your mash process and you might get some more helpful tips.

Yes, tighter will help. Mill the grain as fine as you can as that lets the starches gelatinize quicker which it the starting point for conversion. Mashing longer than 60 minutes should not be necessary if the grain is milled properly. My mashes are never over 40 minutes and usually only 30 because I have full conversion by then.if you are already milling at credit card thickness I don't think any tighter will help.

But if you are only mashing 60 minutes, then yes, 90 might help out.

Most conversion happens in the first 20-30 minutes. But lingering starches take a while.

But you left out mash temps. What are you mashing in at? If too hot, the enzymes are gonna denature too soon. Once that happens it's game over.

Sorry, I should have included that. I do the mash based on what Brewfather says the mash water amount should be after I put in my ingredients and weights for each. I also use the sparge amount as well. I usually do a 60 minute mash somewhere around 150 to 155. I try not to let it get over 155 as I have heard that is where it gets bad. It has gone lower than 150, maybe 148 or so, but I am getting better at keeping a decent control on my temps. I heat my strike water in a 5 gallon kettle to about 170. Once my mash is done, I take the bag and dunk it in the strike kettle. I usually let that sit about 15 mins or so but I don't keep a heat on it. Maybe that is where I am going wrong. Once I am done, I take the strike water out of the kettle and pour it in with my mash water to get about 6.5 to 6.75 gallons for the boil. I usually check my gravity at that time. I guess if I am low, I can just put the bag back into my mash kettle and turn the heat back on. I have not gotten into the lautering but I think I probably should try that as well.Are you sparging or doing a full volume BIAB style?

My method is mash for 60, first batch sparge, lauter for 15 minutes until clear, drain into kettle and then do a 2nd batch sparge for 15 minutes. I typically always hit my numbers or very close to it. I do not crush my own grains either

Elaborate on your mash process and you might get some more helpful tips.

Elaborate on your mash process and you might get some more helpful tips.

strike kettle

Do you mean sparge kettle? At the risk of not having quite followed your narrative, I think there are some improvements to be made in your lauter/sparge process.

1) When mash is complete, pull bag and let fully drain. Squeeze, don't squeeze, make it consistent.

2) Place bag of fully drained grain into sparge bucket. This can be at any temp whatsoever. Open bag, stir to fully homogenize grain into sparge water. Close bag, pull, fully drain. Squeeze, no squeeze, make it consistent.

3) Add 2nd running to 1st.

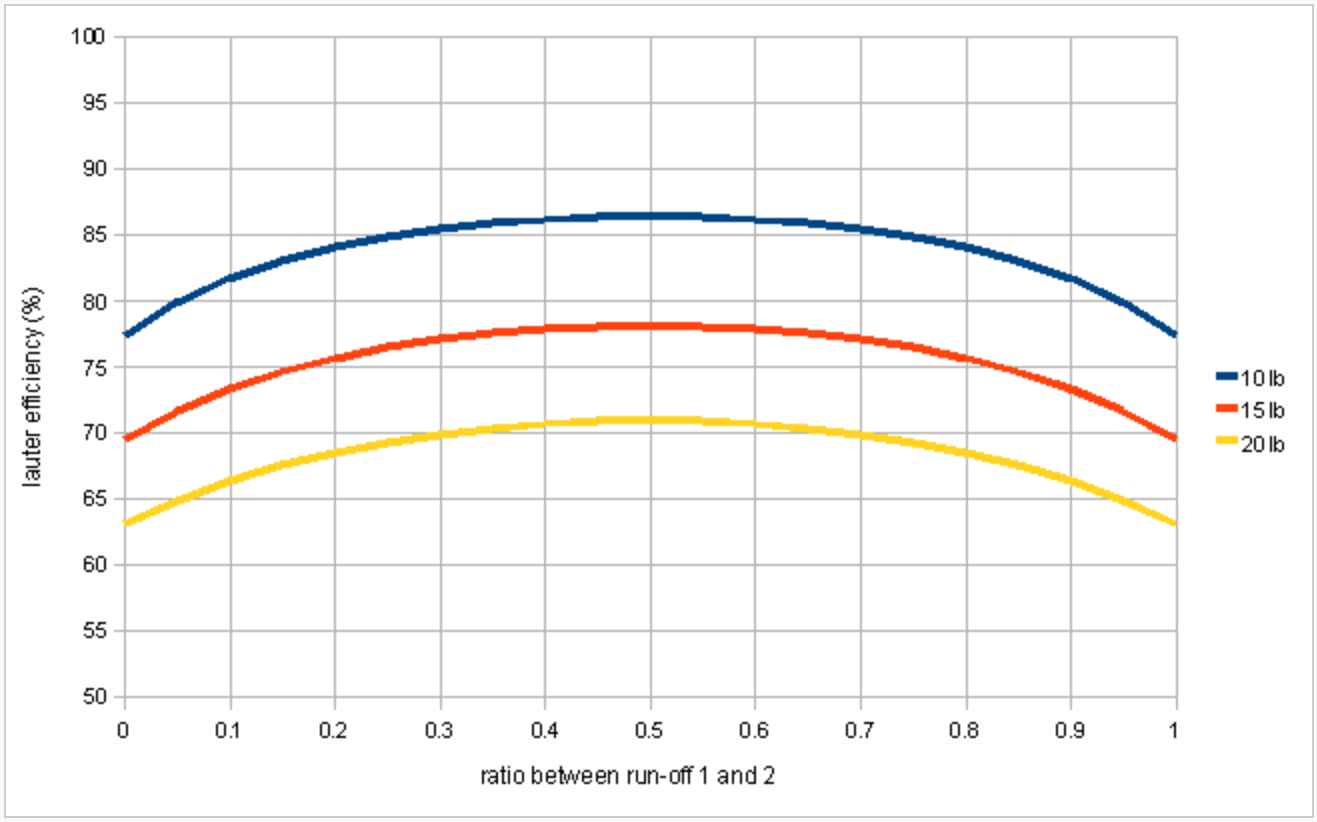

Best lauter efficiency will be found when 1st & 2nd runnings are each 40-60% of pre-boil volume.

I think you've got to clean up the process a bit by doing what DBhomebrew recommends in the previous post.Sorry, I should have included that. I do the mash based on what Brewfather says the mash water amount should be after I put in my ingredients and weights for each. I also use the sparge amount as well. I usually do a 60 minute mash somewhere around 150 to 155. I try not to let it get over 155 as I have heard that is where it gets bad. It has gone lower than 150, maybe 148 or so, but I am getting better at keeping a decent control on my temps. I heat my strike water in a 5 gallon kettle to about 170. Once my mash is done, I take the bag and dunk it in the strike kettle. I usually let that sit about 15 mins or so but I don't keep a heat on it. Maybe that is where I am going wrong. Once I am done, I take the strike water out of the kettle and pour it in with my mash water to get about 6.5 to 6.75 gallons for the boil. I usually check my gravity at that time. I guess if I am low, I can just put the bag back into my mash kettle and turn the heat back on. I have not gotten into the lautering but I think I probably should try that as well.

You want to pull the grain bag from the mash water and let it drain completely (squeeze or no squeeze). You can still have the 2nd kettle ready to go with the sparge water at 170 and drop the bag in there after draining. Make sure to stir. This is basically a batch sparge. After 15 pull the bag and drain completely again.

I'm reiterating what DBhomebrew said but sometimes as a new brewer, it's better to hear again!

I find no benefit to heating sparge water. The difference in fluidity is negligible. Nor in letting the grain sit in the sparge. Dunk, open, stir well, close, pull. If increased temp or time in sparge affects gravity, I suspect the mash hadn't finished.

Yep, that's what I do. I squeeze it like the Italian I am and it owes me money. LOL.I think you've got to clean up the process a bit by doing what DBhomebrew recommends in the previous post.

You want to pull the grain bag from the mash water and let it drain completely (squeeze or no squeeze). You can still have the 2nd kettle ready to go with the sparge water at 170 and drop the bag in there after draining. Make sure to stir. This is basically a batch sparge. After 15 pull the bag and drain completely again.

I'm reiterating what DBhomebrew said but sometimes as a new brewer, it's better to hear again!

Yep, that's what I do. I squeeze it like the Italian I am and it owes me money. LOL.

Ok, but the squeezing is way down on the list of important takeaways. Like I said: "Squeeze, don't squeeze, make it consistent."

Sorry, I am not good with the terms yet. But to sum up, here is my process (this time I will double check before I post, LOL).Do you mean sparge kettle? At the risk of not having quite followed your narrative, I think there are some improvements to be made in your lauter/sparge process.

1) When mash is complete, pull bag and let fully drain. Squeeze, don't squeeze, make it consistent.

2) Place bag of fully drained grain into sparge bucket. This can be at any temp whatsoever. Open bag, stir to fully homogenize grain into sparge water. Close bag, pull, fully drain. Squeeze, no squeeze, make it consistent.

3) Add 2nd running to 1st.

Best lauter efficiency will be found when 1st & 2nd runnings are each 40-60% of pre-boil volume.

I get my mash kettle setup on the burner, add about 5 gallons of water and start bringing it to about 158 to 160. During that I run my grains thru the mill at a thickness of about a credit card. Once my mash water gets to about 158 to 160 I put my bag in and add the grains. Stir to avoid any balls. I drop the heat or turn it off altogether so the mash water gets to about 150 or so. Once I get to that, I add a very small amount of heat and watch the temp like a hawk. If it starts to climb I cut the heat right away and let it get stable. I have it dialed in pretty well that if I keep the burner where there is a hint of blue flame coming out it will keep the temp at about 150. I then move to the kitchen and fill up my sparge kettle with about 2.5 to 3 gallons of water and bring it up to 170ish. Once the 60 min mash is done, I have a rack I put on my mash kettle and lift the bag out and put it on the rack. I then squeeze it like it owes me money. I end up usually around 4 to 4.5 gallons or so. I then transfer the grain bag to my sparge water, dunk it in, stir it up and let it sit for about 15 to 20 mins. I usually stir it at least twice more. The color of the water changes and it looks much like the mash water in the bigger kettle. After about 15 mins or so, I add the sparge water to the mash water and it usually gets me somewhere in the area of 6.5 to 6.75 gallons. My goal is to hit about 5.5 gallons into the fermenter. This has been the practice I have used for the most part, with some water adjustments if I have a larger grain bill as the sparge kettle sometimes overflows if there is too much grain. I have not done any lautering as of now because I did not think I needed to.

To add to the already long post, my mash kettle has a false bottom that I don't use as I am doing BIAB. I am wondering if using that might have some advantage in the end result as I seem to have a lot of stuff at the bottom that clogs up my banjo screen when transferring to the fermenting bucket. LOL. Is everybody still with me? LOL.

I think my next brew will be a bit different. I am going to follow the chart that was posted and determine mash water amount there. Check the mash every 15 mins or so with the refractometer that I just got and see where I am. If it is low, I am going to let the mash go in 15 min increments until It read the same twice. Then, proceed with my sparge water and go from there. I am going to be much more diligent in recording my numbers and process so I can start to adjust as needed to get a consistent result.

Anyway, I want to thank all who have taken the time to add to this. I have read and digested it all and will try and follow the guidance I have been given. Any more input is always welcome, so please, Rock On!!!!!! LOL

I biab and do not sparge at all. I almost always hit my numbers dead-on, (unless I mess something up, which I do on occasion).

Know your boil-off per hour amount.

I would maybe crush a little finer.

I use something like this 12" to measure mash temperature at different spots in the kettle, both before and after mashing in.

Mash for 60 minutes. 90 if you're still seeing efficiency issues. But in most instances I don’t think it’s necessary.

Over several brews take accurate readings: temperature and strike, post-mash, post-boil volume amounts. Note the bh efficiency percentage that your software tells you that you achieved. Update your software with all of these numbers. Review periodically and update software if/when needed.

The more accurate information you input into your software the better it will guide you down the right path on future brews.

Know your boil-off per hour amount.

I would maybe crush a little finer.

I use something like this 12" to measure mash temperature at different spots in the kettle, both before and after mashing in.

Mash for 60 minutes. 90 if you're still seeing efficiency issues. But in most instances I don’t think it’s necessary.

Over several brews take accurate readings: temperature and strike, post-mash, post-boil volume amounts. Note the bh efficiency percentage that your software tells you that you achieved. Update your software with all of these numbers. Review periodically and update software if/when needed.

The more accurate information you input into your software the better it will guide you down the right path on future brews.

Last edited:

Your process sounds reasonable, although you don't really have to wait on the sparge once you have stirred it aggressively to make sure it is well homogenized. All you are doing in this step (assuming conversion was completed in the mash) is rinsing the grain.Sorry, I am not good with the terms yet. But to sum up, here is my process (this time I will double check before I post, LOL).

I get my mash kettle setup on the burner, add about 5 gallons of water and start bringing it to about 158 to 160. During that I run my grains thru the mill at a thickness of about a credit card. Once my mash water gets to about 158 to 160 I put my bag in and add the grains. Stir to avoid any balls. I drop the heat or turn it off altogether so the mash water gets to about 150 or so. Once I get to that, I add a very small amount of heat and watch the temp like a hawk. If it starts to climb I cut the heat right away and let it get stable. I have it dialed in pretty well that if I keep the burner where there is a hint of blue flame coming out it will keep the temp at about 150. I then move to the kitchen and fill up my sparge kettle with about 2.5 to 3 gallons of water and bring it up to 170ish. Once the 60 min mash is done, I have a rack I put on my mash kettle and lift the bag out and put it on the rack. I then squeeze it like it owes me money. I end up usually around 4 to 4.5 gallons or so. I then transfer the grain bag to my sparge water, dunk it in, stir it up and let it sit for about 15 to 20 mins. I usually stir it at least twice more. The color of the water changes and it looks much like the mash water in the bigger kettle. After about 15 mins or so, I add the sparge water to the mash water and it usually gets me somewhere in the area of 6.5 to 6.75 gallons. My goal is to hit about 5.5 gallons into the fermenter. This has been the practice I have used for the most part, with some water adjustments if I have a larger grain bill as the sparge kettle sometimes overflows if there is too much grain. I have not done any lautering as of now because I did not think I needed to.

To add to the already long post, my mash kettle has a false bottom that I don't use as I am doing BIAB. I am wondering if using that might have some advantage in the end result as I seem to have a lot of stuff at the bottom that clogs up my banjo screen when transferring to the fermenting bucket. LOL. Is everybody still with me? LOL.

I think my next brew will be a bit different. I am going to follow the chart that was posted and determine mash water amount there. Check the mash every 15 mins or so with the refractometer that I just got and see where I am. If it is low, I am going to let the mash go in 15 min increments until It read the same twice. Then, proceed with my sparge water and go from there. I am going to be much more diligent in recording my numbers and process so I can start to adjust as needed to get a consistent result.

Anyway, I want to thank all who have taken the time to add to this. I have read and digested it all and will try and follow the guidance I have been given. Any more input is always welcome, so please, Rock On!!!!!! LOL

I don't think your lauter and sparge processes are part of your problem. You are either not getting enough conversion during the mash, or your inputs to your brewing software are not correct, so you are getting unrealistic expectations. If you list one of your recipes here, including water volumes, actual wort volumes, and boil-off, I can give you a pretty good idea of what your process should give you, independent of whatever brewhouse efficiency you input to your software.

It appears that you misunderstand just what "lautering" is. Lautering is separating wort from the spent grain. Simply draining wort from a mash tun or lifting the grain bag to drain are lautering. You appear to be using the term lautering to refer to fly (or continuous) sparging. Fly sparging is a form of lautering, but not the only way to lauter.

Brew on

Honestly, it sounds like a rock solid process. Doesn't sound like you should have efficiency problems. Maybe try a finer crush on the grainsSorry, I am not good with the terms yet. But to sum up, here is my process (this time I will double check before I post, LOL).

I get my mash kettle setup on the burner, add about 5 gallons of water and start bringing it to about 158 to 160. During that I run my grains thru the mill at a thickness of about a credit card. Once my mash water gets to about 158 to 160 I put my bag in and add the grains. Stir to avoid any balls. I drop the heat or turn it off altogether so the mash water gets to about 150 or so. Once I get to that, I add a very small amount of heat and watch the temp like a hawk. If it starts to climb I cut the heat right away and let it get stable. I have it dialed in pretty well that if I keep the burner where there is a hint of blue flame coming out it will keep the temp at about 150. I then move to the kitchen and fill up my sparge kettle with about 2.5 to 3 gallons of water and bring it up to 170ish. Once the 60 min mash is done, I have a rack I put on my mash kettle and lift the bag out and put it on the rack. I then squeeze it like it owes me money. I end up usually around 4 to 4.5 gallons or so. I then transfer the grain bag to my sparge water, dunk it in, stir it up and let it sit for about 15 to 20 mins. I usually stir it at least twice more. The color of the water changes and it looks much like the mash water in the bigger kettle. After about 15 mins or so, I add the sparge water to the mash water and it usually gets me somewhere in the area of 6.5 to 6.75 gallons. My goal is to hit about 5.5 gallons into the fermenter. This has been the practice I have used for the most part, with some water adjustments if I have a larger grain bill as the sparge kettle sometimes overflows if there is too much grain. I have not done any lautering as of now because I did not think I needed to.

To add to the already long post, my mash kettle has a false bottom that I don't use as I am doing BIAB. I am wondering if using that might have some advantage in the end result as I seem to have a lot of stuff at the bottom that clogs up my banjo screen when transferring to the fermenting bucket. LOL. Is everybody still with me? LOL.

I think my next brew will be a bit different. I am going to follow the chart that was posted and determine mash water amount there. Check the mash every 15 mins or so with the refractometer that I just got and see where I am. If it is low, I am going to let the mash go in 15 min increments until It read the same twice. Then, proceed with my sparge water and go from there. I am going to be much more diligent in recording my numbers and process so I can start to adjust as needed to get a consistent result.

Anyway, I want to thank all who have taken the time to add to this. I have read and digested it all and will try and follow the guidance I have been given. Any more input is always welcome, so please, Rock On!!!!!! LOL

I always do a mash thickness of 1.33 qts/lb of grain. I tend to sparge with more water then I mash with. Sounds like you have the opposite approach. I couldn't tell you if it makes a difference or not.. probably does

I'll leave ya alone now. Good luck!

When single batch sparging, the maximum lauter efficiency is achieved when the initial runnings, and the sparge runnings have the same volume. But, if the ratio is anywhere between about 60:40 to 40:60, the difference from max efficiency is less than 0.5%. The formulas for hitting the max efficiency are (no matter what your brewing software tells you):I tend to sparge with more water then I mash with. Sounds like you have the opposite approach. I couldn't tell you if it makes a difference or not.. probably does

Strike volume = Target Pre-boil volume / 2 + expected grain absorption

Sparge volume = Target Pre-boil volume / 2

Braukaiser chart

When fly sparging you want to mash as thick as you can handle, and sparge until you reach your pre-boil volume (or sparge runnings drop below 1.010 SG, in which case just add water to hit your pre-boil target.)

Brew on

Thank you, and yes, I will start being much more diligent in my recording of process and numbers during my brew day. This is all good stuff. Thank you all for the input. Keep it coming. Rock On!!!!!!!I biab and do not sparge at all. I almost always hit my numbers dead-on, (unless I mess something up, which I do on occasion).

Know your boil-off per hour amount.

I would maybe crush a little finer.

I use something like this 12" to measure mash temperature at different spots in the kettle, both before and after mashing in.

Mash for 60 minutes. 90 if you're still seeing efficiency issues. But in most instances I don’t think it’s necessary.

Over several brews take accurate readings: temperature and strike, post-mash, post-boil volume amounts. Note the bh efficiency percentage that your software tells you that you achieved. Update your software with all of these numbers. Review periodically and update software if/when needed.

The more accurate information you input into your software the better it will guide you down the right path on future brews.

Thank you for the offer, I will for sure take you up on it. I have to go thru my notes and organise them better. My next brew will be in a week or two, so that one I will really make good notes and post them. Might even PM you with them if that's ok. My next brew I am going to tighten up the mill a bit and see where that gets me. Maybe it's time to get a handle on the water chemistry? Either way, thanks for taking the time, and thanks to all. I am getting closer I think, but still have a ways to go. Rock On!!!!!!!!!Your process sounds reasonable, although you don't really have to wait on the sparge once you have stirred it aggressively to make sure it is well homogenized. All you are doing in this step (assuming conversion was completed in the mash) is rinsing the grain.

I don't think your lauter and sparge processes are part of your problem. You are either not getting enough conversion during the mash, or your inputs to your brewing software are not correct, so you are getting unrealistic expectations. If you list one of your recipes here, including water volumes, actual wort volumes, and boil-off, I can give you a pretty good idea of what your process should give you, independent of whatever brewhouse efficiency you input to your software.

It appears that you misunderstand just what "lautering" is. Lautering is separating wort from the spent grain. Simply draining wort from a mash tun or lifting the grain bag to drain are lautering. You appear to be using the term lautering to refer to fly (or continuous) sparging. Fly sparging is a form of lautering, but not the only way to lauter.

Brew on

You can PM me, or post here.Thank you for the offer, I will for sure take you up on it. I have to go thru my notes and organise them better. My next brew will be in a week or two, so that one I will really make good notes and post them. Might even PM you with them if that's ok. My next brew I am going to tighten up the mill a bit and see where that gets me. Maybe it's time to get a handle on the water chemistry? Either way, thanks for taking the time, and thanks to all. I am getting closer I think, but still have a ways to go. Rock On!!!!!!!!!

Water chemistry isn't all that hard to deal with if you use software like Brun'Water. The big thing for the mash is to make sure you have 50+ ppm of calcium (needed for the enzymes to work well, and also for yeast health later) and the mash pH is in the range of about 5.2 - 5.7. The only chemicals you really need to adjust water chemistry are calcium sulfate (gypsum), calcium chloride, lactic acid (88% is best), and maybe either baking soda or pickling lime (calcium hydroxide) if you are brewing dark beers. You either need to get a water report for you tap water that lists alkalinity, calcium, magnesium, iron, sulfate, chloride (not chlorine), nitrates, manganese and iron (the last three just need to be low for good tasting beer), or start with reverse osmosis (RO) water, and build up the ions from scratch. Water dispensers in supermarkets are usually RO water, and home RO systems are available for reasonable cost.

Brew on

RR, I agree with Doug, water chemistry doesn't have to be overly complicated. Brun'Water takes the mystique out of it, and a lot of brewing software includes a water adjustment tool. Also, per a Ward Labs' test my water sucks for brewing, and I don't want to install an RO system in my house. So I get my RO water from my local Culligan dealer. Not sure if you have one conveniently nearby, and if so if yours would even offer this, but at mine I pre-paid for 250 gallons of RO for $75, (.30 cents/gallon). I went to WalMart and bought three 3-gallon jugs with handles to use. I just go to Culligan, fill my jugs and they swipe my Culligan card which deducts from my 250 gallons. Much cheaper than buying from a grocer's shelf. Plus, I've always been a little weary of supermarket RO dispensers, maybe unfairly so but they're just something I don't wish to deal with.

Why do you need to keep the flame on? If you're not stirring constantly you most likely are denaturing enzymes. I use a 15 gal Spike kettle with 2 layers of refletex and a comforter on top and only loose 2 degrees in 90 min.

I leave the flame on ever so slightly to keep my mash temp at about 150. I just got one of those really heavy moving blankets and am going to look at the local Lowe's for some of that wrap insulation. Like what you would use on a water heater, or the reflective stuff. I just thought keeping the flame on so just a hint of blue is coming out would be ok. I stir the mash probably every 15 mins or so. I have to be careful though as my temp probe sticks into the kettle pretty far and I don't want to rip the bag. All great info, thank you all. Keep it coming. Rock On!!!!!!!!!!!Why do you need to keep the flame on? If you're not stirring constantly you most likely are denaturing enzymes. I use a 15 gal Spike kettle with 2 layers of refletex and a comforter on top and only loose 2 degrees in 90 min.

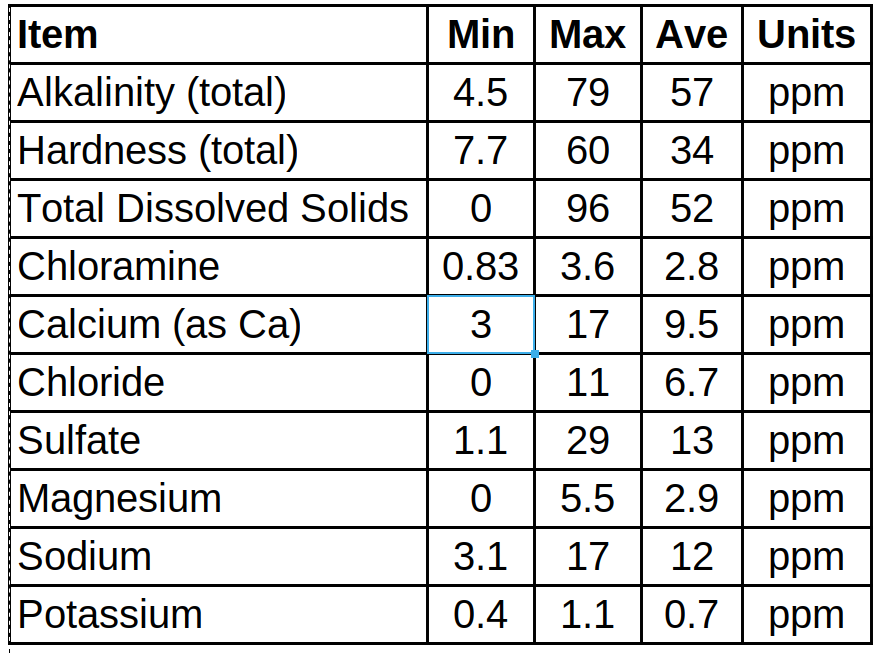

This is what I found when I types in Water quality report. Long read, so if anybody could dumb it down for me I would appreciate it. Also, are there any home tests that I can buy?

https://www.calwater.com/ccrs/bay-ssf-2021/

https://www.calwater.com/ccrs/bay-ssf-2021/

I have extracted and rearranged the most important info from that water report. This water looks like a good starting point for brewing (although the report says nothing about iron content, I suspect it is low enough not to be a problem since everything else is pretty low.)This is what I found when I types in Water quality report. Long read, so if anybody could dumb it down for me I would appreciate it. Also, are there any home tests that I can buy?

https://www.calwater.com/ccrs/bay-ssf-2021/

Just feed the average values into your chosen water calculator software, and go from there. If you want an idea how much difference the range of values would affect you, then take a recipe and calculate and adjust mash pH to about 5.45 using the average values, and then again using both the min and max values. If the projected pH stays within acceptable limits for all cases, then you are pretty safe just using the average values, and not worrying about the variability.

Your water does contain chloramine as a disinfectant, and this will give your beers a plasticy off-taste. You will need to treat all of your brewing water with campden (sodium or potassium metabisulfite) to get rid of the chloramine. One tablet (~650 mg) is enough to treat 10 gal. Using powdered campden or crushed tablets will get the campden to dissolve faster. Action is pretty instantaneous, so no need to wait after treatment.

Brew on

Last edited:

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 72

- Views

- 4K

- Replies

- 19

- Views

- 1K

- Replies

- 24

- Views

- 3K