I usually hard crash for 24-48hours, let the fermenter warm back up to 60-65F, add the rehydrated CBC + priming solution (dextrose) to the fermenter, purge headspace, wait 2-3 hours to see signs of activity, and then transfer to kegs. I don’t use spunding valves since I’m adding a measured amount of priming solution—enough to raise the gravity of the entire volume in the fermenter by 3 gravity points. Just purge the headspace of the keg (or transfer into water/sanitizer/fermentation purged kegs) and then seal with a blast of 30-40 psi. Then I let them carbonate at room temperature (usually takes 24–48 hours) and start slowly dropping the temperature to 32-34F until I’m ready to tap.How and at what temps do you condition? Do you use a spunding valve to keep the pressure in check?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Isolated Yeast (Tree House): How to Identify and Characterize?

- Thread starter isomerization

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

beervoid

Hophead & Pellet Rubber

Ok so it only takes up to 2 days to get the carbonation where you need it?I usually hard crash for 24-48hours, let the fermenter warm back up to 60-65F, add the rehydrated CBC + priming solution (dextrose) to the fermenter, purge headspace, wait 2-3 hours to see signs of activity, and then transfer to kegs. I don’t use spunding valves since I’m adding a measured amount of priming solution—enough to raise the gravity of the entire volume in the fermenter by 3 gravity points. Just purge the headspace of the keg (or transfer into water/sanitizer/fermentation purged kegs) and then seal with a blast of 30-40 psi. Then I let them carbonate at room temperature (usually takes 24–48 hours) and start slowly dropping the temperature to 32-34F until I’m ready to tap.

troxerX

Well-Known Member

- Joined

- Feb 6, 2016

- Messages

- 172

- Reaction score

- 84

I have been using CBC1 to naturally carbonate all of my APA/IPA’s for the last year or so. It doesn’t add anything perceptible in the form of flavor or esters. It allows the base yeast character to remain intact. It also doesn’t add much from a bio-transformation perspective (I fermenter prime/add CBC after dry hopping).

What it DOES add is an incredible mouthfeel that is very soft and full bodied. Even in the absence of adjuncts or high chloride levels. You can push sulfate to 300-400ppm and still get a soft/rounded beer with great aromatics. My last NEIPA was a perfect example of that. It was a Pearl single malt + dextrose with approx 350ppm sulfate that was incredibly soft. CBC is also VERY resistant to hop creep/diacetyl. Which makes it a truly awesome conditioning strain for these beers.

@MrPowers that sounds awesome, thanks for sharing. This is one of the keys to the mouthfeel puzzle. Also it’s ‘undetectible’ to be diastaticus by Lallemand (see Lallemand link in previous post #3658) and will not keep munching on your complex sugars thus keeping the sweeter side of things intact.

I was looking into a description of their Gggreennn:

Any ideas on how can someone pack larger and larger hop additions without impacting the drinkability of a beer or making it too bitter, green, off putting and that will not tire your palate?

I usually let it sit for a week, because my spunding valve only reads 15PSI, so if I check it it will explode. But I have checked it at 24-48 hours before and it’s usually fully carbonated at that point.Ok so it only takes up to 2 days to get the carbonation where you need it?

@MrPowers that sounds awesome, thanks for sharing. This is one of the keys to the mouthfeel puzzle. Also it’s ‘undetectible’ to be diastaticus by Lallemand (see Lallemand link in previous post #3658) and will not keep munching on your complex sugars thus keeping the sweeter side of things intact.

Any ideas on how can someone pack larger and larger hop additions without impacting the drinkability of a beer or making it too bitter, green, off putting and that will not tire your palate?

The problem that I run into is the amount of loss with dry hops much over 1.25oz/gallon. I can’t imagine trying to deal with even 2oz/gallon. I’m already doing 12 gallon batches just to get 10 into kegs at 1.25oz/gal.

Last edited:

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,063

- Reaction score

- 2,256

Anytime I’ve naturally carbonated a hoppy beer I felt like the beer had less hop aroma than if I had force carbed. I do think it benefits the mouthfeel and flavor doesn’t seem to change that much but aroma is never has good. I’d say Tree House beers don’t seem to have great hop aroma. Plenty of yeast esters, but lacking in hop aroma for sure.

It does mute hop aroma slightly, but I think the oxygen reduction benefits are worth it. You will have more aroma with force carbing though.Anytime I’ve naturally carbonated a hoppy beer I felt like the beer had less hop aroma than if I had force carbed. I do think it benefits the mouthfeel and flavor doesn’t seem to change that much but aroma is never has good. I’d say Tree House beers don’t seem to have great hop aroma. Plenty of yeast esters, but lacking in hop aroma for sure.

Ideally, I'd like to have a unitank that I could spund the beer, drop the yeast, and then dry hop the already carbonated beer. But, $$$.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

About the Beer: Spunding and Slurming Updates they could be doing something like this. Just because Nate said on Twitter they don’t spund or whatever doesn’t mean they don’t do something similar.

It would most likely be in the form of adding CBC1 + priming sugar to the fermenter/bright tank. If they're doing that in the fermenter, there isnt anything stopping them from dry hopping after it's carbonated/crashed. It would take some extra equipment to avoid beer volcano's, but it's certainly possible.About the Beer: Spunding and Slurming Updates they could be doing something like this. Just because Nate said on Twitter they don’t spund or whatever doesn’t mean they don’t do something similar.

Yeah a hop cannon. They had one or two in Monson. The CBC or killer wine yeast could just be used to stop the other yeast. Pitch the primary yeast to get fruity esters and then pitch the killer strain after 12 hours or so to stop the other yeast from developing clove or whatever off flavors. Thinking out loud here lolIt would most likely be in the form of adding CBC1 + priming sugar to the fermenter/bright tank. If they're doing that in the fermenter, there isnt anything stopping them from dry hopping after it's carbonated/crashed. It would take some extra equipment to avoid beer volcano's, but it's certainly possible.

Nate’s beers were so phenomenal back in the day could he have really been doing things so complicated five years ago? Have there been talks from any other brewers about a killer yeast strain regularly used in brewing? I have no idea so educate me.

Has anyone ever gotten any TH esters from just S04? Stressing, under pitching, fermenting hot?

I haven’t had a fresh TH beer in awhile. Maybe 6-8 months ago I had some and I thought all the beers tasted the same. Every, single, one. The beers were slightly old, maybe three weeks. But I did love their Bright beers, the American Ale yeast really allowed the hops to shine.

Has anyone ever gotten any TH esters from just S04? Stressing, under pitching, fermenting hot?

I haven’t had a fresh TH beer in awhile. Maybe 6-8 months ago I had some and I thought all the beers tasted the same. Every, single, one. The beers were slightly old, maybe three weeks. But I did love their Bright beers, the American Ale yeast really allowed the hops to shine.

I’ve played with S04, T58, and WB06. I’ve try blending all 3 post fermentation as well. Ive never been able to produce anything that resembles TH esters.Nate’s beers were so phenomenal back in the day could he have really been doing things so complicated five years ago? Have there been talks from any other brewers about a killer yeast strain regularly used in brewing? I have no idea so educate me.

Has anyone ever gotten any TH esters from just S04? Stressing, under pitching, fermenting hot?

I haven’t had a fresh TH beer in awhile. Maybe 6-8 months ago I had some and I thought all the beers tasted the same. Every, single, one. The beers were slightly old, maybe three weeks. But I did love their Bright beers, the American Ale yeast really allowed the hops to shine.

Clyde McCoy

Well-Known Member

- Joined

- Mar 1, 2020

- Messages

- 205

- Reaction score

- 231

I’ve played with S04, T58, and WB06. I’ve try blending all 3 post fermentation as well. Ive never been able to produce anything that resembles TH esters.

What ratios have you tried? I just plated another can of Julius and based on colony morphology I would guess >97% are S-04-like (haven't tested yet).

My earlier co-pitch comment was based on the quote from Chris White "if your goal is flavor, you need to add the multiple strains early on, preferably together."

They were awhile back so I don’t remember the ratios, but in terms of co-pitching I never went as high as 97% with S04. I also tried staggering, had really bad luck there. Blending produced a good beer but wasn’t like TH. And it was a pain in the @ss (I hate using glass w/pressure transfers and used 1G carboys for t58 and wb06) so I only tried twice.What ratios have you tried? I just plated another can of Julius and based on colony morphology I would guess >97% are S-04-like (haven't tested yet).

My earlier co-pitch comment was based on the quote from Chris White "if your goal is flavor, you need to add the multiple strains early on, preferably together."

It’s interesting that you’re finding mostly S04 in Julius but we’re able to find T58 in Green. That distinct TH flavor is in both, but always comes through stronger in Julius for me. To me Green is a beer that pulls a lot of its flavor from Galaxy, but gets support from the malt bill and esters. I still think Julius gets a relatively small amount of hops for this style and focuses more on the esters. JJJ screams Citra, as where regular Julius does not.

beervoid

Hophead & Pellet Rubber

Really curious what Nate would think of this thread. I guess he feels honored people put so much time in cloning his beers. Who knows one day they will open source a recipe.

Till then the myth continues and this thread will maybe one day crack the code.

3600+ posts in. Is this the largest HBT thread?

Till then the myth continues and this thread will maybe one day crack the code.

3600+ posts in. Is this the largest HBT thread?

What ratios have you tried? I just plated another can of Julius and based on colony morphology I would guess >97% are S-04-like (haven't tested yet).

My earlier co-pitch comment was based on the quote from Chris White "if your goal is flavor, you need to add the multiple strains early on, preferably together."

I think S-04 is being stressed a specific way which lends a lot of what we are all chasing. I believe it would be kept more simple than blending. I will also agree that their beers do taste very similar although Super Treat is my new favorite and I do taste some “bubble gum.”

I think it’s clear s04 is a major player here, but I don’t think it’s the only contributor in regards to the flavor we‘re chasing. I’ve been under the impression that their core IPA’s are DH’d prior to the end of fermentation - do we know that to be true? If that is true, which conflicts with what I believe we know about their bright/us05, then I’m pretty convinced the answer to these questions have to do with that alternative process.I think S-04 is being stressed a specific way which lends a lot of what we are all chasing. I believe it would be kept more simple than blending. I will also agree that their beers do taste very similar although Super Treat is my new favorite and I do taste some “bubble gum.”

beervoid

Hophead & Pellet Rubber

They mentioned in a description they foregoed the fermentation dry hopping.I think it’s clear s04 is a major player here, but I don’t think it’s the only contributor in regards to the flavor we‘re chasing. I’ve been under the impression that their core IPA’s are DH’d prior to the end of fermentation - do we know that to be true? If that is true, which conflicts with what I believe we know about their bright/us05, then I’m pretty convinced the answer to these questions have to do with that alternative process.

Noob_Brewer

Well-Known Member

got a noob question here. With dry yeast, how do we really know if we are under pitching or not given that Mr. Malty says dry yeast is 20 billion cells per gram yet Brewers friend suggests that Fermentis SO4 is 6 billion cells per gram. Also how consistent really are these dry packets in terms of number of cells per gram? Seems to me that these wide margins in estimating how much yeast is indeed in each packet might contribute to the wide array of outcomes reported here in HBT when using SO4. Sorry if this has been answered already but 20B vs 6B is a HUGE difference especially when peeps are trying to hit the sweet spot with using S04.

Have you tested an Equilibrium beer yet? I’m curious to see what that shows. I get that over ripe banana ester in some of their beers.What ratios have you tried? I just plated another can of Julius and based on colony morphology I would guess >97% are S-04-like (haven't tested yet).

My earlier co-pitch comment was based on the quote from Chris White "if your goal is flavor, you need to add the multiple strains early on, preferably together."

Could be something “similar” to s04. I’m not sure if these tests are an exact match, @Clyde McCoy and @isomerization know better. There are some yeast that look similar in these genetic tests.I think it’s clear s04 is a major player here, but I don’t think it’s the only contributor in regards to the flavor we‘re chasing. I’ve been under the impression that their core IPA’s are DH’d prior to the end of fermentation - do we know that to be true? If that is true, which conflicts with what I believe we know about their bright/us05, then I’m pretty convinced the answer to these questions have to do with that alternative process.

JohnConnor

Well-Known Member

- Joined

- Jan 6, 2017

- Messages

- 149

- Reaction score

- 59

For what it's worth, I emailed fermentis a while ago asking them about S-04. Everytime I've used it, I get nothing but yeast bread notes. Their suggestion was to increase pitch rate and temperature. Increased pitch rate produces more esters due to the availability of acetyl CoA. Haven't had a chance to give this a try.

Northeast IPA thread has 12,888 posts as of yesterdayReally curious what Nate would think of this thread. I guess he feels honored people put so much time in cloning his beers. Who knows one day they will open source a recipe.

Till then the myth continues and this thread will maybe one day crack the code.

3600+ posts in. Is this the largest HBT thread?

brewpharm Hill

Well-Known Member

Based on looking at the temp panel they could be pitching at lower temps and raising the temp slightly each day similar to a saison fermentation. Wouldn't hurt trying to pitch S04 with a small amount of T58 and WB06 at like 59-60 and letting it increase each day up to about 66.

I brewed a batch a month or two ago with a new scale and using the Mr. malty calculator. I did the referenced blend percentages from the Trinity clone. Pitched at 70 and then down to 62-63 for the remainder. The samples that I pulled were the closest I've come until I naturally carbonated with CBC1. I was away for the weekend so my apartment was easily in the mid 90s and I'm pretty sure it woke up some yeast still in suspension because after that I could taste the WB06/T58 coming through more. Probably happened as the CBC1 was waking up before it could suppress it.

The aroma of the beer was definitely reminiscent of TH but not quite there.

My Grainfather's cord melted into the control box, so until they send a replacement I'll be out of the experimenting game.

I brewed a batch a month or two ago with a new scale and using the Mr. malty calculator. I did the referenced blend percentages from the Trinity clone. Pitched at 70 and then down to 62-63 for the remainder. The samples that I pulled were the closest I've come until I naturally carbonated with CBC1. I was away for the weekend so my apartment was easily in the mid 90s and I'm pretty sure it woke up some yeast still in suspension because after that I could taste the WB06/T58 coming through more. Probably happened as the CBC1 was waking up before it could suppress it.

The aroma of the beer was definitely reminiscent of TH but not quite there.

My Grainfather's cord melted into the control box, so until they send a replacement I'll be out of the experimenting game.

Clyde McCoy

Well-Known Member

- Joined

- Mar 1, 2020

- Messages

- 205

- Reaction score

- 231

Could be something “similar” to s04. I’m not sure if these tests are an exact match, @Clyde McCoy and @isomerization know better. There are some yeast that look similar in these genetic tests.

Certainly possible, but I doubt it. Isomerization tested ~two dozen strains. Nothing looked identical to S-04. Whatever's in Julius, jjjuliusss, and Very Green is an exact match to S-04.

I will test 71B and F-2 in a few weeks.

- Joined

- Nov 15, 2017

- Messages

- 23

- Reaction score

- 19

HopsAreGood

Well-Known Member

I had a can of gggreennn on Sunday night and I noticed absolutely zero hint of the typical yeast esters that this entire thread is based on. My friend who shared the can with me said he’s had a lot of treehouse lately and has barely been noticing it at all. Take it for whatever it’s worth.

Clyde McCoy

Well-Known Member

- Joined

- Mar 1, 2020

- Messages

- 205

- Reaction score

- 231

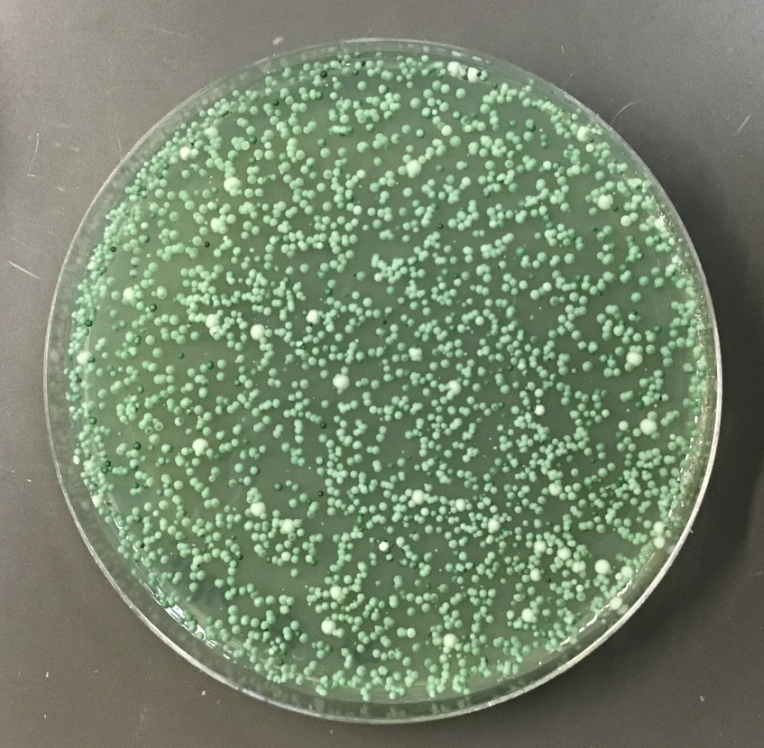

Has this been discussed?

View attachment 697388

from;

https://fermentis.com/en/yeast-to-brew-a-neipa/

That post is a result of this thread

- Joined

- Nov 15, 2017

- Messages

- 23

- Reaction score

- 19

That's what it seemed like!

So, has anything S-33 or k-97 'like' ever showed up in analysis? any possibility that either of those could resemble T-58 and/or Wb-06?

If the hottest craft brewer on the planet is(or was) using their yeast, you'd think Fermentis would want to tell the world about it. (I'm sure they are somewhat limited legally but I think they would still hint at it...)

of course TH has said that their 'house yeast blend' is 'irreplicable', whatever that means.

"we wanted to see how it would work with our House yeast blend..." -Curiosity 99

" utilizes our irreplicable House yeast. " Curiosity 100

So, has anything S-33 or k-97 'like' ever showed up in analysis? any possibility that either of those could resemble T-58 and/or Wb-06?

If the hottest craft brewer on the planet is(or was) using their yeast, you'd think Fermentis would want to tell the world about it. (I'm sure they are somewhat limited legally but I think they would still hint at it...)

of course TH has said that their 'house yeast blend' is 'irreplicable', whatever that means.

"we wanted to see how it would work with our House yeast blend..." -Curiosity 99

" utilizes our irreplicable House yeast. " Curiosity 100

- Joined

- Nov 15, 2017

- Messages

- 23

- Reaction score

- 19

Of those strains, I've only tested S-33. Definitely did not see see anything matching that profile in this can.

Bumping this (from July) for context.

Clyde McCoy

Well-Known Member

- Joined

- Mar 1, 2020

- Messages

- 205

- Reaction score

- 231

That's what it seemed like!

So, has anything S-33 or k-97 'like' ever showed up in analysis? any possibility that either of those could resemble T-58 and/or Wb-06?

If the hottest craft brewer on the planet is(or was) using their yeast, you'd think Fermentis would want to tell the world about it. (I'm sure they are somewhat limited legally but I think they would still hint at it...)

of course TH has said that their 'house yeast blend' is 'irreplicable', whatever that means.

"we wanted to see how it would work with our House yeast blend..." -Curiosity 99

" utilizes our irreplicable House yeast. " Curiosity 100

So far, the answer to both of your questions is no. Irreplicable means "we're really good at marketing."

This is from a different can of Julius (July 2, 2020):

Those small dark green and medium green colonies (almost everything on the plate) are S-04-like. Still accounting for the rest.

A few members have asked why it isn't all F-2/CBC-1. My guess is that those strains take over only in the presence of carbohydrates, oxygen and other nutrients.

Similar threads

- Replies

- 86

- Views

- 23K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)