BitterSweetBrews

Tim Trabold

I brewed on Sunday, May 6th during a Club teach a friend to homebrew / AHA Big Brew Day event. We brewed two beers, the AHA suggested Charlie Papasian - Rocky Racoon Honey Lager and a Pre-Prohibition Lager. I have 5 gallons of each.

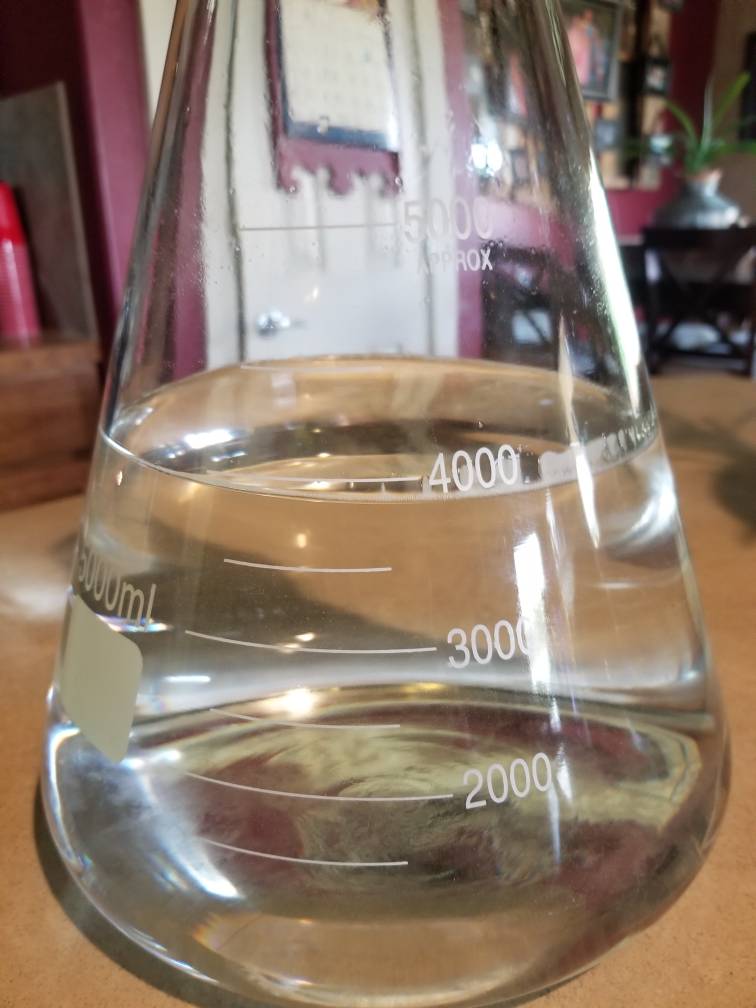

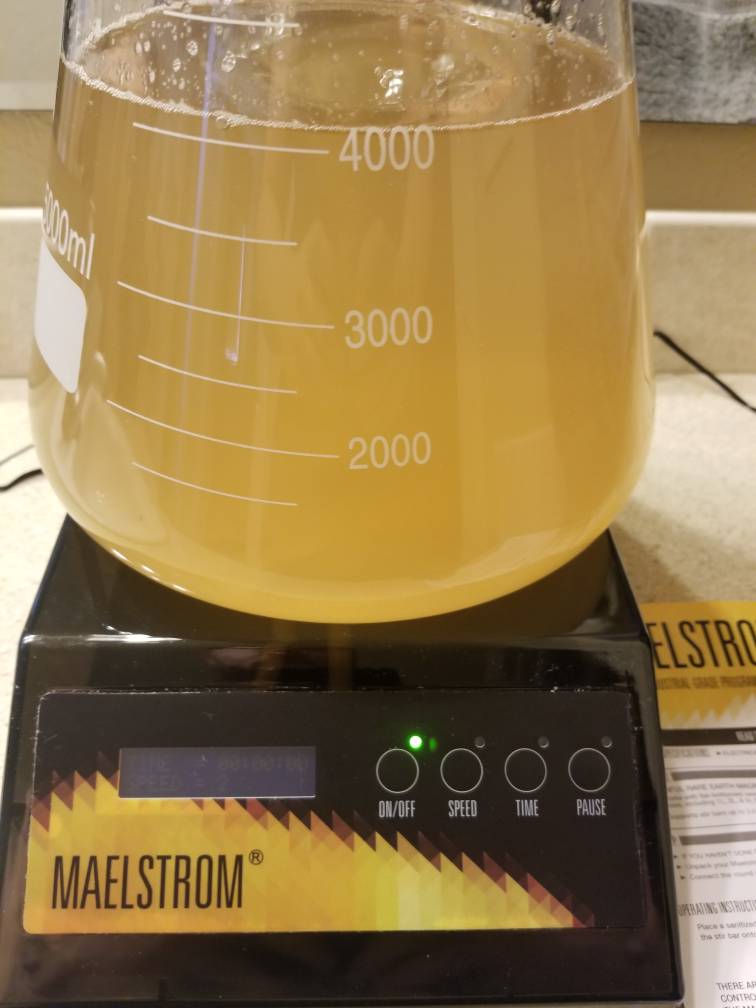

I made a 2 quart starter of White WLP800 Pilsner Yeast from a pack that expired on May 10th. The starter was going fine on the stir plate for 3 days before pitching. On Sunday night, I pitched half of the starter in each Beer. According to the White Labs package it says that for 10 gallons of 1.065 wort you need one package and a 2 liter starter. I figured 2 quarts was close enough. The Honey lager was at 1.050 and the pre-prohibition lager was at 1.065. On Sunday night after pitching the first yeast I thought twice about the volume and decided to make a pint starter out of another pack of the same yeast and some yeast nutrient. I pitched half of it into each fermenter on Monday night, 24 hours later. It had already started to bubble in both fermenters.

I started fermentation at 60F degrees for 12 hours then lowered it to 55F, then to where it is now at 53F. Ideal temp for the yeast is between 50F and 55F degrees.

The beer has now been fermenting for 9 days. The Racoon has gone from 1.050 to 1.028 (42% attenuation). It went down .002 points in the last two days. The Pre-Prohibition has gone from 1.065 to 1.035 (43.8% attenuation). It went down .007 points in the last 2 days. BeerSmith predicts FG of 1.005 and 1.012 respectively.

So, is this normal for this yeast? I realize and am fully aware that 9 days is not a real long time for a lager, but usually they seem to attenuate a bit faster. Should I swirl the fermenters to rouse the yeast? Since both beers are attenuating at about the same rate am I just being paranoid?

I planned on raising the temp once it hits 50% attenuation, per the Brulosophy Quick Lager Method, for a diacetyl cleanup. I would like to get these into kegs before June 1st, when we have a party.

I made a 2 quart starter of White WLP800 Pilsner Yeast from a pack that expired on May 10th. The starter was going fine on the stir plate for 3 days before pitching. On Sunday night, I pitched half of the starter in each Beer. According to the White Labs package it says that for 10 gallons of 1.065 wort you need one package and a 2 liter starter. I figured 2 quarts was close enough. The Honey lager was at 1.050 and the pre-prohibition lager was at 1.065. On Sunday night after pitching the first yeast I thought twice about the volume and decided to make a pint starter out of another pack of the same yeast and some yeast nutrient. I pitched half of it into each fermenter on Monday night, 24 hours later. It had already started to bubble in both fermenters.

I started fermentation at 60F degrees for 12 hours then lowered it to 55F, then to where it is now at 53F. Ideal temp for the yeast is between 50F and 55F degrees.

The beer has now been fermenting for 9 days. The Racoon has gone from 1.050 to 1.028 (42% attenuation). It went down .002 points in the last two days. The Pre-Prohibition has gone from 1.065 to 1.035 (43.8% attenuation). It went down .007 points in the last 2 days. BeerSmith predicts FG of 1.005 and 1.012 respectively.

So, is this normal for this yeast? I realize and am fully aware that 9 days is not a real long time for a lager, but usually they seem to attenuate a bit faster. Should I swirl the fermenters to rouse the yeast? Since both beers are attenuating at about the same rate am I just being paranoid?

I planned on raising the temp once it hits 50% attenuation, per the Brulosophy Quick Lager Method, for a diacetyl cleanup. I would like to get these into kegs before June 1st, when we have a party.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)