You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IDEA: Ultimate Mash Tun

- Thread starter Yuri_Rage

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Philip1993

Well-Known Member

- Joined

- Jul 5, 2007

- Messages

- 1,644

- Reaction score

- 19

My $0.02 WAG;

Excepting the steam input, what you are designing is much like a homemade ice cream churn. Since those have been remained unchanged (except power source) for nearly a century, I would assume that the paddle design employed is the dominant of several less effective designs.

Excepting the steam input, what you are designing is much like a homemade ice cream churn. Since those have been remained unchanged (except power source) for nearly a century, I would assume that the paddle design employed is the dominant of several less effective designs.

LouT

Can't wait to go AG...

For the mixing, if the steam could enter from the top opening, could you go with something like this:

http://www.constructioncomplete.com...rtarMixers-BuffaloToolsCME35ConcreteMixer.jpg

http://www.constructioncomplete.com...rtarMixers-BuffaloToolsCME35ConcreteMixer.jpg

I'm so interested to see what Yuir finds out with this project.

Grimsawyer

Well-Known Member

wortmonger said:I'm so interested to see what Yuir finds out with this project.

Speaking if which, how's this coming along?

Still in the idea stages. I think I have a pretty good direction for it. I'm going to design it pretty close to the depiction, but the paddles will be fewer, as suggested elsewhere in this thread. I think I'm also going to see about injecting the steam through the rotating assembly rather than the bottom (though I'll likely still use a two-port manifold, just for overall design flexibility).

Mostly, I have to finish a few other projects and scrape together a few hundred bucks before tackling this one. I can't wait, either!

Mostly, I have to finish a few other projects and scrape together a few hundred bucks before tackling this one. I can't wait, either!

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

Skrimpy

Well-Known Member

I keep checking back here to see what the status is. I suppose that if you had done something at this point you would have posted. Man I wish I could weld. I would have a sculpture in no time flat, instead I waste my time trying to find kegs, and then if I finally find them I will waste my time trying to find someone to do the welding.

I plan on building something like this in the spring, I am taking a welding class at college. Its not related to my major but then I am graduating this spring and you gotta take a couple of the underwater basketweaving type classes for fun. I want to convert my brewery to all SS and the first thing I am gonna build is a hlt to keep my hot liqueur at the right temp - good bye stove top multiple pan set up! Do you think this design could be incorporated with a false bottom? I would like to keep the mash in one spot. This web page: http://brewingtechniques.com/library/backissues/issue2.6/put.html

looks like a good start for the paddle design

looks like a good start for the paddle design

For those of you holding your breath to see how this turns out...don't. All of my projects are pretty much on hold until this summer. I'm moving in a couple of months, and I need to focus on selling the house and getting things ready to go. As soon as I move into the new place, I plan on a major brewery upgrade, to include this mash tun.

Well then F-you and good luck all in the same sentence. LOL, I hear you. I am selling my house in Lubbock and can't do much until. I am like an addict though Yuri, your shizzle has me feaming for more. Good luck on the home sale and hope your market is good there. I will be hawking this thread to wait for the build

LouT

Can't wait to go AG...

Are you planning to bring the steam in from above, through the paddles, and make the vessel turn, or are you planning to turn/spin the steam carrying paddles - I guess option 1 seems simpler...

Glad to see you've stuck with this idea, I'm looking forward to seeing the end result!

Glad to see you've stuck with this idea, I'm looking forward to seeing the end result!

Steaming, spinning paddles seems like the best idea for eliminating hot spots. I think I'm going to attempt that. I will likely still put two input/output valves on the manifold just to keep flexibility in the design.

I foresee difficulty, expense and possible danger in a rotary coupling capable of steam pressure.

Why not just scale down a normal **************** design that uses steam in a double wall tun, and simply paddle stir to equalize the mash temperature?

Why not just scale down a normal **************** design that uses steam in a double wall tun, and simply paddle stir to equalize the mash temperature?

I had thought about a home brew steam jacket at one time way back when I was designing my first next brewery, lol. I wondered, if taking a 50-55 gallon open head barrel with lid and lid lock, and cutting a hole in the lid big enough for a 30 gallon open head barrel to fit and then be welded (open in of 30 to lid of 50-55)? If both were stainless steel, and you welded/plumbed the steam-in port and what ever relief valve system you had in mind into the lid and floor, would the barrels be able to hold much pressure? Does it even take anything more than steam rushing through the jacket? I haven't seen a jacketed system unless glycol counts, lol.

Now, I think it would be great to have a steam jacketed mash tun, but I think it is way more economical to blast steam directly from the bottom while being stirred. I think your temperature rise would take a little longer to achieve. I don't know about how steam couplers stand up or anything like that (as earlier with my knowledge on steam jackets). It does sound more complicated to send steam through the paddle; when (as I have read the trials in threads here) steam directly injected gives its energy to the wort so fast, heat rises all on its own, and it is easy to inject from the bottom and simply automatically stir just like Yuri's picture. I really want to try this on my system as soon as I build another stirrer. This time not out of copper$$$, and for myself not my best friend!!!

Now, I think it would be great to have a steam jacketed mash tun, but I think it is way more economical to blast steam directly from the bottom while being stirred. I think your temperature rise would take a little longer to achieve. I don't know about how steam couplers stand up or anything like that (as earlier with my knowledge on steam jackets). It does sound more complicated to send steam through the paddle; when (as I have read the trials in threads here) steam directly injected gives its energy to the wort so fast, heat rises all on its own, and it is easy to inject from the bottom and simply automatically stir just like Yuri's picture. I really want to try this on my system as soon as I build another stirrer. This time not out of copper$$$, and for myself not my best friend!!!

I foresee fun!Henry Hill said:I foresee difficulty, expense and possible danger in a rotary coupling capable of steam pressure.

Why not just scale down a normal **************** design that uses steam in a double wall tun, and simply paddle stir to equalize the mash temperature?

Not so sure that a double-walled steam mash tun would be a whole lot easier...

mr x

Well-Known Member

Nah, piece of cake.:rockin:Henry Hill said:I foresee difficulty, expense and possible danger in a rotary coupling capable of steam pressure

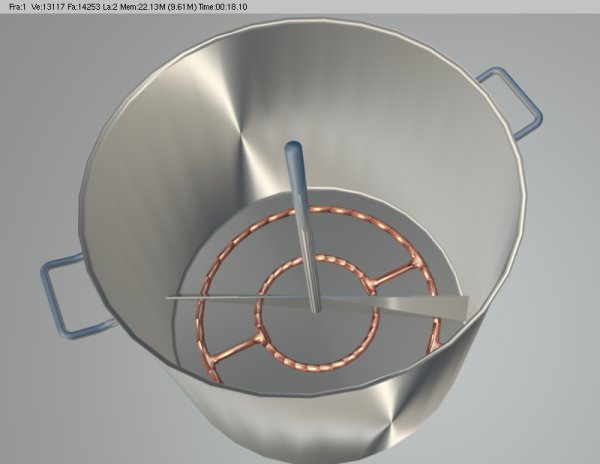

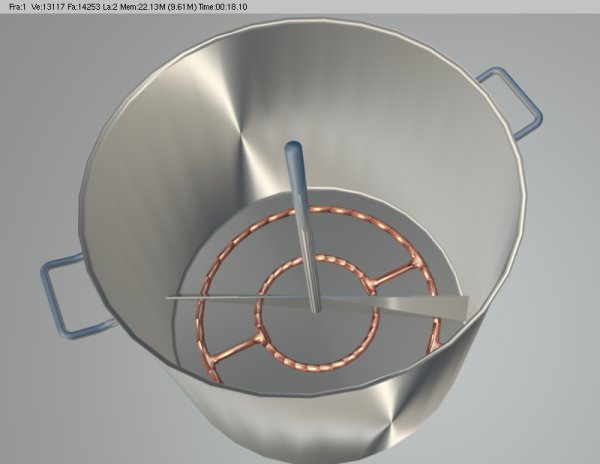

Like I posted earlier this week...my projects have hit "virtual land" for now. Here are a few renderings of the "Ultimate Mash Tun." I still have to model the stir paddle support and drive system and the fittings on the tun exterior. The copper manifold is upside down, showing the slits in the bottom (most likely, the actual manifold will have holes, but slits were easier to model).

Certainly, the design is subject to change, but this should give you a pretty good idea of the finished product.

Certainly, the design is subject to change, but this should give you a pretty good idea of the finished product.

Grimsawyer

Well-Known Member

I've got a question. The steam generated. Is it all going to become liquid or will there be any air trapped under the false bottom? I only ask this because I've had my fair share of fun priming a high temp, food grade, magneticly coupled pump once or twice from air trapped under a false bottom. Not fun.

There is no air in steam - it's solely water vapor. As soon as the superheated steam hits the 150°-ish degree mash water, it changes state back to water (giving up its heat energy to the mash). No chance for HSA, no chance for trapped air pockets forming.Grimsawyer said:I've got a question. The steam generated. Is it all going to become liquid or will there be any air trapped under the false bottom? I only ask this because I've had my fair share of fun priming a high temp, food grade, magneticly coupled pump once or twice from air trapped under a false bottom. Not fun.

Funny you should post here today. I finally got some of the parts I need for the upgraded rig. The boiler is getting an update, and I will soon be purchasing another kettle for the mash tun. I expect the new rig to be operational later this summer (as the finishing touch to the new brew hut).

I'm going to do some trial runs with a steam mixing system like kladue uses. If that goes well, there will be little need to stir during infusion. If not, I'll explore the steam paddle idea some more.

No luck yet with the pH sensor...mostly due to moving and focusing on the brew hut.

I'm going to do some trial runs with a steam mixing system like kladue uses. If that goes well, there will be little need to stir during infusion. If not, I'll explore the steam paddle idea some more.

No luck yet with the pH sensor...mostly due to moving and focusing on the brew hut.

Hi Yuri,

Is Kladue's that inline steam diffuser into the wort, like a RIMS using steam rather than an element?

For the Mash Tun, I don't suppose you are working on a 'double shell' or 'pot within pot' with insulation between are you? If so, have you posted on this design anywhere?

Also, if you do ever get back to steam through the paddles, which I am flirting with myself right now, what do you think of coupling a gear motor to one of these (select swivel joints in the 'Groupings' pull down menu): http://www.ryco.com.au/AdaptorGrouping.aspx

Cheers.

Is Kladue's that inline steam diffuser into the wort, like a RIMS using steam rather than an element?

For the Mash Tun, I don't suppose you are working on a 'double shell' or 'pot within pot' with insulation between are you? If so, have you posted on this design anywhere?

Also, if you do ever get back to steam through the paddles, which I am flirting with myself right now, what do you think of coupling a gear motor to one of these (select swivel joints in the 'Groupings' pull down menu): http://www.ryco.com.au/AdaptorGrouping.aspx

Cheers.

JKoravos

Well-Known Member

Any update on this?

I'm working on a stirred steam injection system as well. Hopefully, to be up and running by year end.

I'm working on a stirred steam injection system as well. Hopefully, to be up and running by year end.

And so it begins:

The Blichmann 30 gallon BoilerMaker false bottom just happens to fit nicely inside the 20 gallon MegaPot sold by Northern Brewer. I'll need to fabricate a collar to deal with the minor gap around the circumference, but I don't anticipate that being difficult. Also, I plan on draining through the bottom of the mash/lauter tun rather than the side.

As usual...progress will be slow, but check back for updates.

The Blichmann 30 gallon BoilerMaker false bottom just happens to fit nicely inside the 20 gallon MegaPot sold by Northern Brewer. I'll need to fabricate a collar to deal with the minor gap around the circumference, but I don't anticipate that being difficult. Also, I plan on draining through the bottom of the mash/lauter tun rather than the side.

As usual...progress will be slow, but check back for updates.

Excellent - glad to see you getting back to this!

Any update on this?

I'm working on a stirred steam injection system as well. Hopefully, to be up and running by year end.

Cool! They are the best. mine is about 2 years old. It was finished just before we moved. Don't have a shed yet, but you can see the cooler on the shelf. the black thing on top is the motor. One of those pressure cookers is the boiler. Steam enters the bottom of the stir arm and exits holes in the stir bars. Step mashes are so nice with this rig.

Once the brewery is set up again, i'll put up some photos.

Good luck on your build.

Great! And what a fantastic beginning. I'm sure it will be something to dazzle the eye, knowing what your other projects looked like...And so it begins:

Good luck, and have fun.

Cool! They are the best. mine is about 2 years old. It was finished just before we moved. Don't have a shed yet, but you can see the cooler on the shelf. the black thing on top is the motor. One of those pressure cookers is the boiler. Steam enters the bottom of the stir arm and exits holes in the stir bars. Step mashes are so nice with this rig.

Once the brewery is set up again, i'll put up some photos.

Good luck on your build.

Great stuff.

What did you use as the connecting bit that allows injection of steam and revolution of shaft?

Right to the heart of it. There is a bunch of my junk still boxed and stacked in the shop or I'd send a photo now. when I get it out I'll post then.Great stuff.

What did you use as the connecting bit that allows injection of steam and revolution of shaft?

The part you are interested in is machined from Teflon 1 1/2" rod stock. Both ends are female. one end is 3/8" NPT. The other end is machined to fit over 3/8" 304 stainless pipe. There is a shoulder for the pipe to rest against and a groove for an "O" ring. the pipe is polished where it fits down into the fitting.

later....

Similar threads

- Replies

- 2

- Views

- 677

- Replies

- 0

- Views

- 2K

- Replies

- 0

- Views

- 592

- Replies

- 11

- Views

- 1K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)