After starting with making hard cider last november and then progressing to all grain brewing, I have finally gotten tired of only having half a refrigerator to use for beer and using my entire house as a fermentation chamber. Moving carboys to warmer or cooler spots (or moving them to the basement and then back upstairs) and constantly changing the thermostat got old real quick.

I was inspired by "The Mother of All Fermentation Chillers" from the Wort-O-Matic site and I wanted it to look like like an old style icebox since my house is on the old side (1908). One of the main driving factors of the design was to make something that I could still use as a cabinet if I ever stop brewing my own beer/cider.

So far I have the design 95% complete and sourced my raw materials. Hopefully I will be able to start putting it together soon.

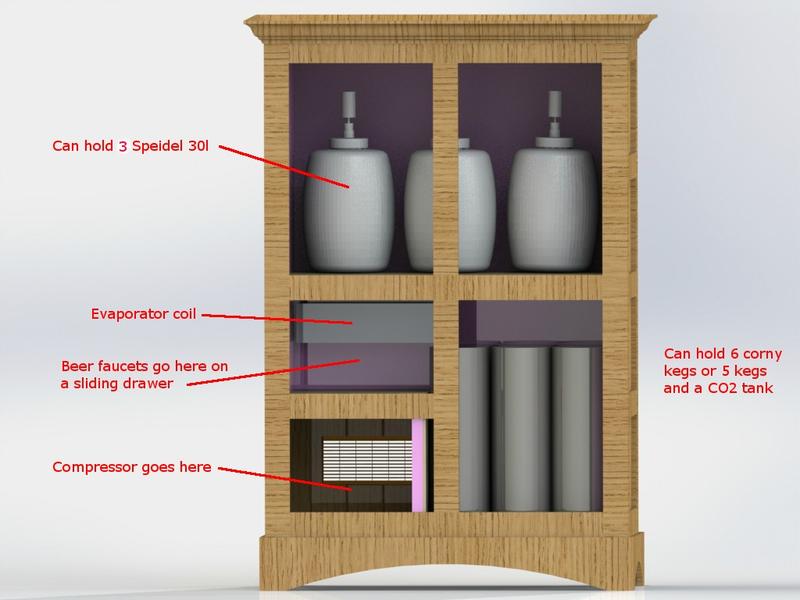

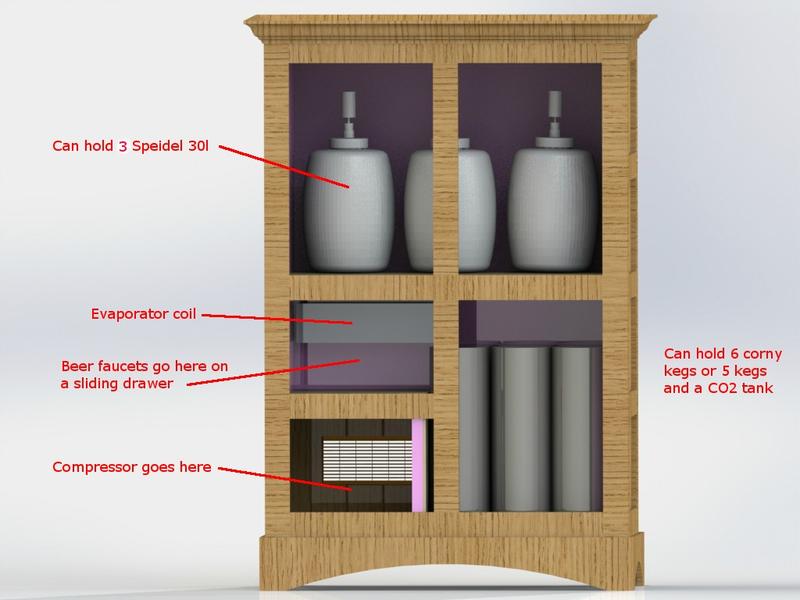

The design:

Old style icebox "look" made out of Michigan knotty red pine. I will stain it, but I haven't decided on what color to use. I don't want to go too dark and lose the character of the knotty pine. Or I may just Briwax it with one of their colored waxes.

I have the icebox hinges and latches on order. Hopefully they will be here soon.

Overall size is 51" wide, 24" deep, and 80" tall.

Front View:

A bit of a schematic:

The Components:

The refrigeration deck from a vending machine will be used instead of a chest freezer or mini refrigerator:

The knotty red pine lumber from WoodHaven Log & Lumber got delivered today. This is a mixture of their S4S boards and tongue and groove paneling. It is some fantastic stuff (my crappy photos don't do it justice). Milled right here in Michigan. You can't find this quality of lumber at any big box store:

I was inspired by "The Mother of All Fermentation Chillers" from the Wort-O-Matic site and I wanted it to look like like an old style icebox since my house is on the old side (1908). One of the main driving factors of the design was to make something that I could still use as a cabinet if I ever stop brewing my own beer/cider.

So far I have the design 95% complete and sourced my raw materials. Hopefully I will be able to start putting it together soon.

The design:

Old style icebox "look" made out of Michigan knotty red pine. I will stain it, but I haven't decided on what color to use. I don't want to go too dark and lose the character of the knotty pine. Or I may just Briwax it with one of their colored waxes.

I have the icebox hinges and latches on order. Hopefully they will be here soon.

Overall size is 51" wide, 24" deep, and 80" tall.

Front View:

A bit of a schematic:

The Components:

The refrigeration deck from a vending machine will be used instead of a chest freezer or mini refrigerator:

The knotty red pine lumber from WoodHaven Log & Lumber got delivered today. This is a mixture of their S4S boards and tongue and groove paneling. It is some fantastic stuff (my crappy photos don't do it justice). Milled right here in Michigan. You can't find this quality of lumber at any big box store:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)