Giuseppe Orlandi

Member

- Joined

- Mar 24, 2023

- Messages

- 8

- Reaction score

- 0

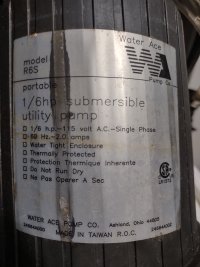

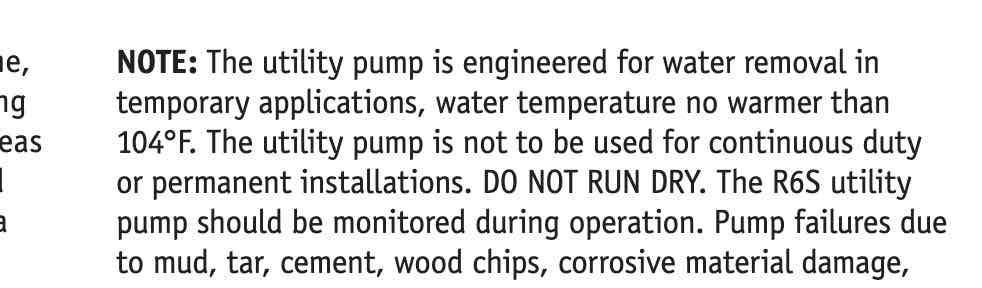

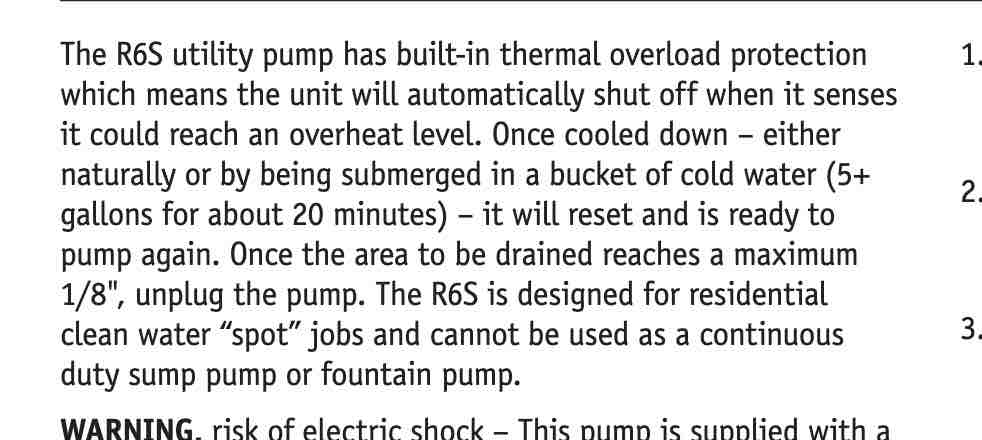

Hi all friends I need some brotherly advice I have tried in every way but I can't get the 4 inch Kegland cip ball to work both with the high pressure water network and with the magnetic pump which I attach photos with specifications I rely on you and your experience.... if I turn the cip ball with my hand the ball turns freely... I attach the whole configuration and thank you in advance

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)