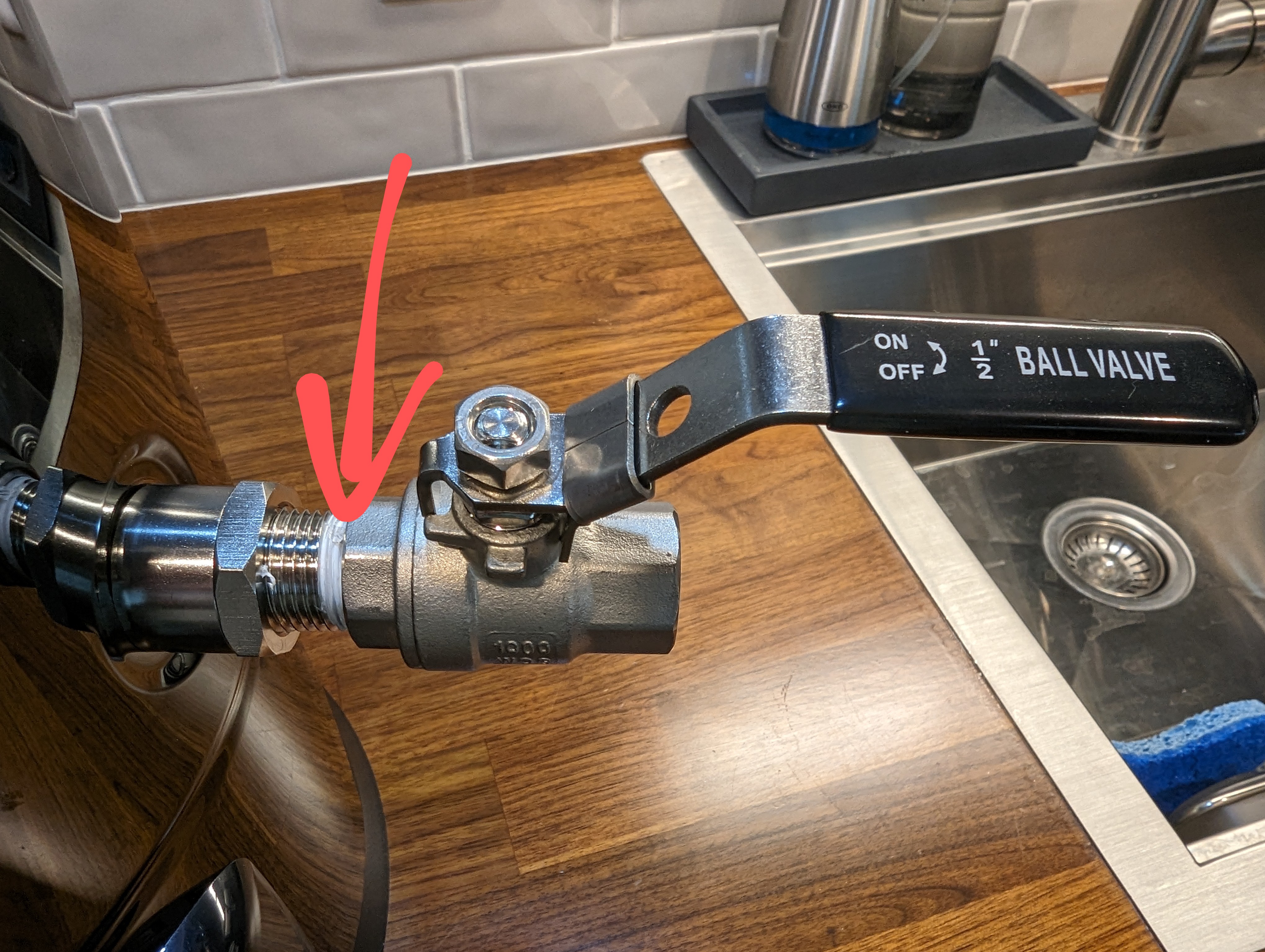

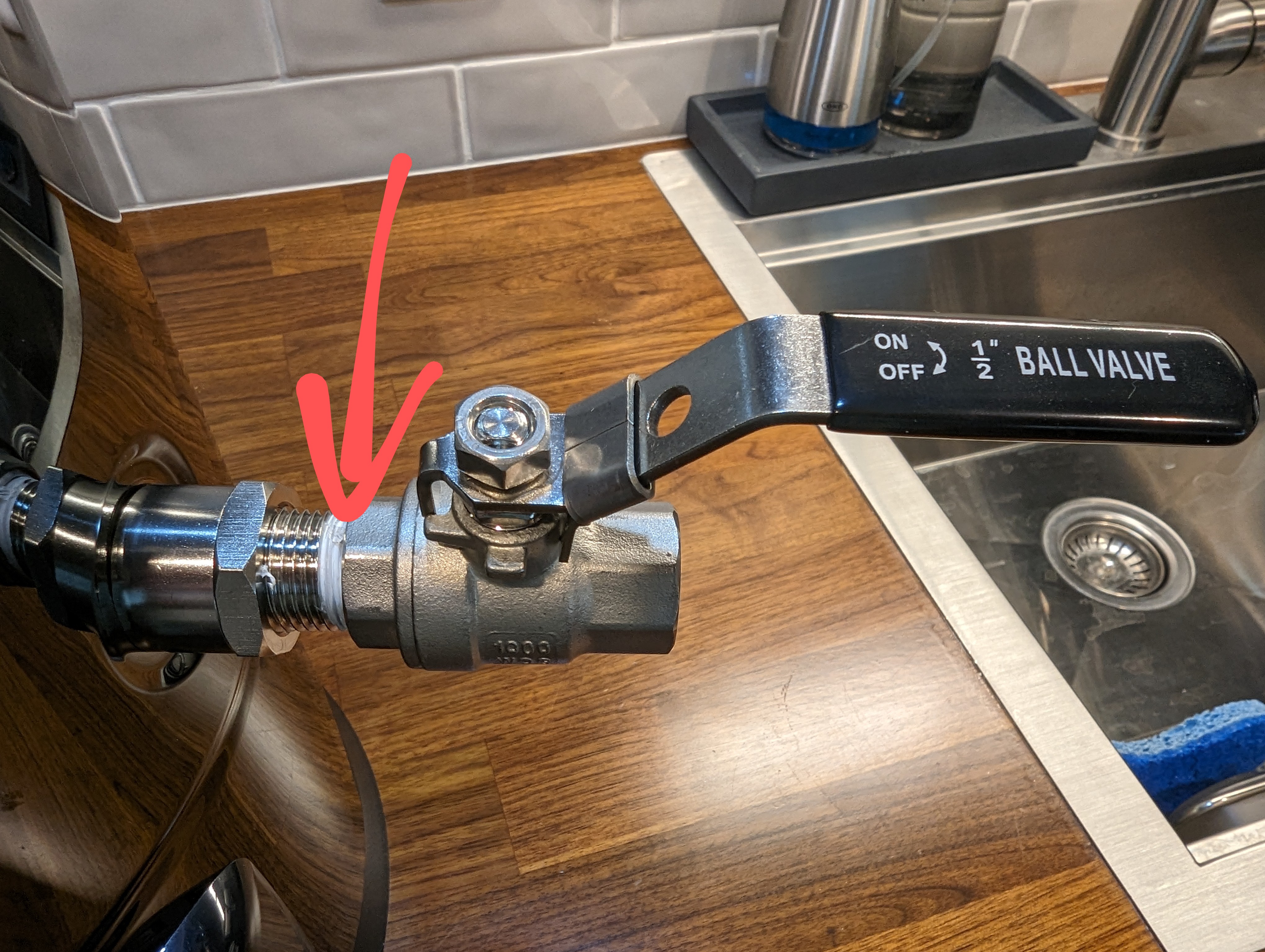

I was going to take my Gigawort for its maiden voyage soon but after doing a leak test it's leaking where the main body/nipple screws into the ball valve (hope I'm using the correct terminology; see pic -- arrow pointing to where it's leaking).

The problem is I can't screw the ball valve in tighter into the main body but I also can't take the thing apart and take another run at assembling the whole thing better from scratch.

Before explaining the problem here's a photo of the parts from the instructions so people know what the heck parts I'm talking about.

To explain this as best I can, the issue is the the main body (the part with the visible threads that's sticking out of the Gigawort body) spins in the same direction as the ball valve and without resistance from the main body the ball valve can't be tightened or loosened.

I got a pipe thread wrench with plastic teeth since I don't want to damage the threads by just clamping the hell out of it with a pair or pliers or something, but unfortunately it doesn't hold tightly enough and the whole thing still spins.

Anyone have any tips or tricks to either tighten or loosen this thing? I don't mind buying the right tools to handle this since if it happened once it'll happen again, or maybe I'm just totally missing something here.

Thanks!

The problem is I can't screw the ball valve in tighter into the main body but I also can't take the thing apart and take another run at assembling the whole thing better from scratch.

Before explaining the problem here's a photo of the parts from the instructions so people know what the heck parts I'm talking about.

To explain this as best I can, the issue is the the main body (the part with the visible threads that's sticking out of the Gigawort body) spins in the same direction as the ball valve and without resistance from the main body the ball valve can't be tightened or loosened.

I got a pipe thread wrench with plastic teeth since I don't want to damage the threads by just clamping the hell out of it with a pair or pliers or something, but unfortunately it doesn't hold tightly enough and the whole thing still spins.

Anyone have any tips or tricks to either tighten or loosen this thing? I don't mind buying the right tools to handle this since if it happened once it'll happen again, or maybe I'm just totally missing something here.

Thanks!