What is this "dual plug socket with usb integrated" that you speak of? Do you mean a "wall wart" type of power adapter that has two USB-style power receptacles?

Cheers!

Cheers!

What is this "dual plug socket with usb integrated" that you speak of? Do you mean a "wall wart" type of power adapter that has two USB-style power receptacles?

Cheers!

This is what I speak of -> http://www.amazon.co.uk/dp/B00B9G6YO0/?tag=skimlinks_replacement-20

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

At idle they should be off. If they are lit then change the inverted state. If whatever is hooked up up to the relay is on when light is off then you have the relay side hooked up backwards.

You'd have to have setup the host name to be brewpi. Also you'd have to have a home network that allows domain names internally. Does your password protected site work. Because the error message you talk about isn't an error message, it's telling you that you don't have a qualified domain name, which is fine.

Don't ask me I don't care for password protection nor do I know anything about php script. I just know I've seen a lot of people freak out because it have them an "error" when it's not an error it's just an unnamed server in the domain.

Raspberry Pi Model A+ Is Smaller, Thinner, and Just $20 http://lifehacker.com/raspberry-pi-model-a-is-smaller-thinner-and-just-20-1656837626

Also only one USB slot and no Ethernet port. Although, with a USB hub and a WiFi dongle I suppose you could get away with it.

Damn what kind of airlocks are you using that your fermenters will blow up?

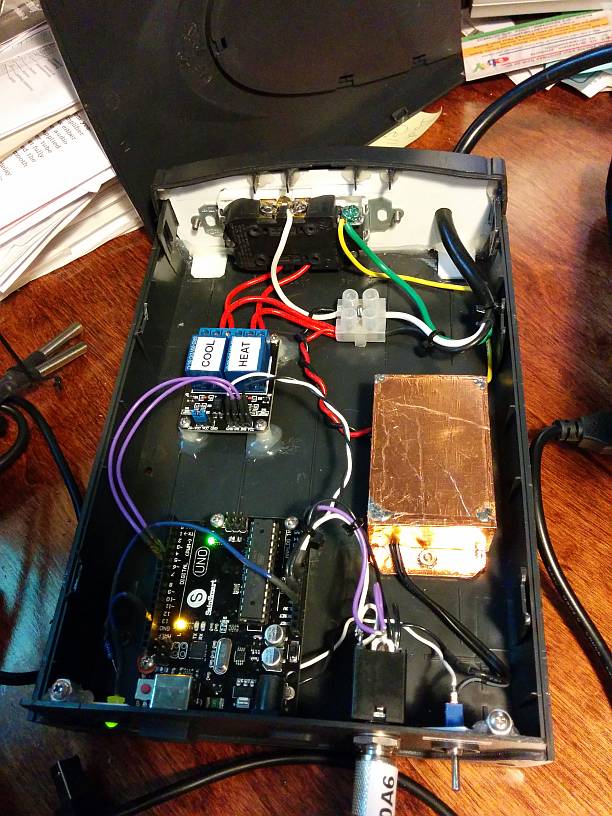

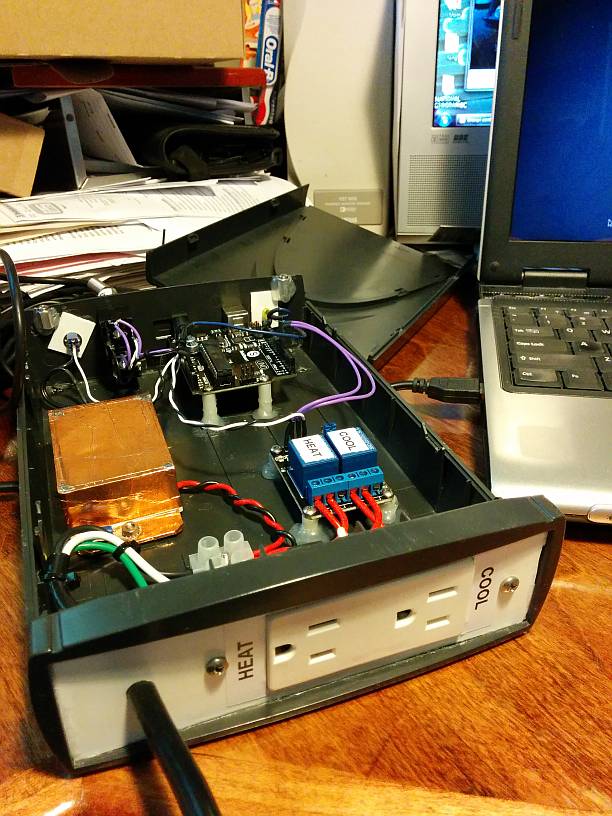

Cold weather is here and we're about to hit a freeze, so I figure I need to find a heat source for my chamber. It's a 15.5 cuft chest freezer. I found this small space heater locally available at walmart: http://www.walmart.com/ip/Pelonis-Fan-Forced-Heater-with-Thermostat/21804031 . It's similar to the small Lasco that OP links in the first post.

What do you guys have to say about the safety of using one of these? I ask because I woke up this morning to find about 1/2" of beer and starsan on the bottom of the freezer from blow-off overflow. If I hadn't expected blow-off this time and not used the blow-off hose, it surely would have exploded in there and drenched any heater that I may have had. I'm no electrician, but that seems like it would cause a bad day.

Do I need GFCI protection? What other safety measures are you all taking? Should I look into more "moisture friendly" heating options, if so what are they?

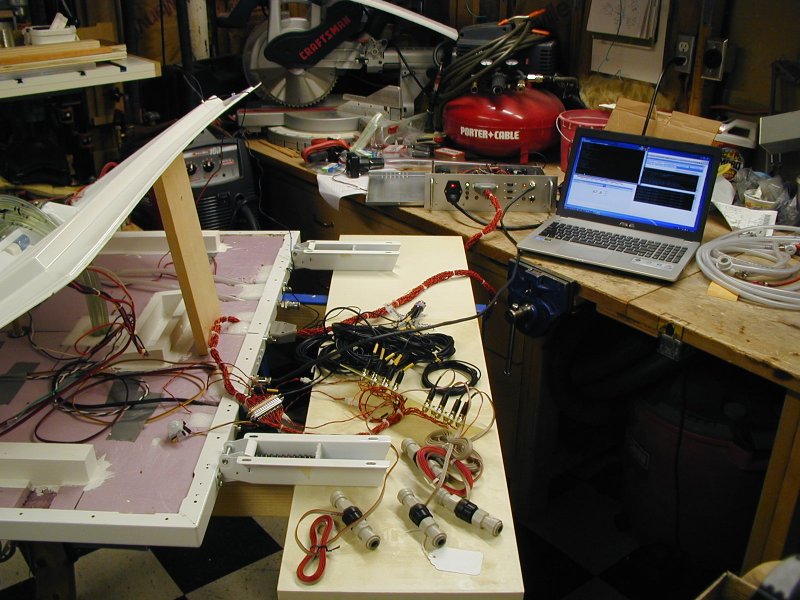

I used 1/4" stereo "headphone" plugs/jacks and I don't recommend them because they will short 2 of wires together as you insert the plug. I added a power switch so I could turn off the arduino while plugging/unplugging (and yes, I also need to unplug the USB cord). mini-XLRs would be perfect but they're really expensive. DIN plugs are probably good for this application.

In my opinion, the CAT3/Telephone connections are the best connection to use. My problem with the mini xlr is the length of the plug. I bought a 12' telephone cord and cut it in half, giving me (2) 6' cables. But I built by own temperature probes.