I'm fortunately to have an old-school e-hobby store a half hour away, and they carry pretty near every imaginable diameter of shrink wrap tubing.

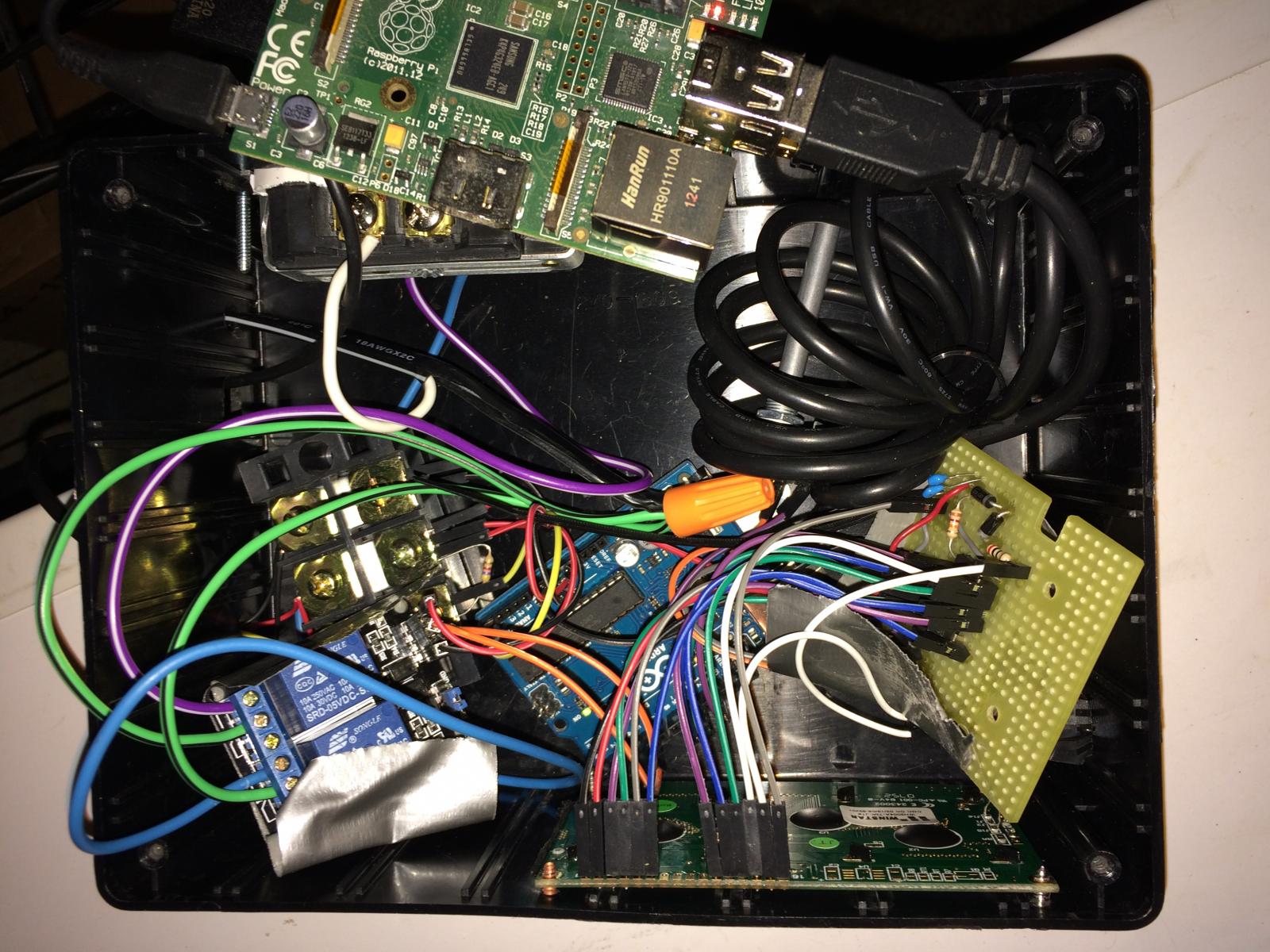

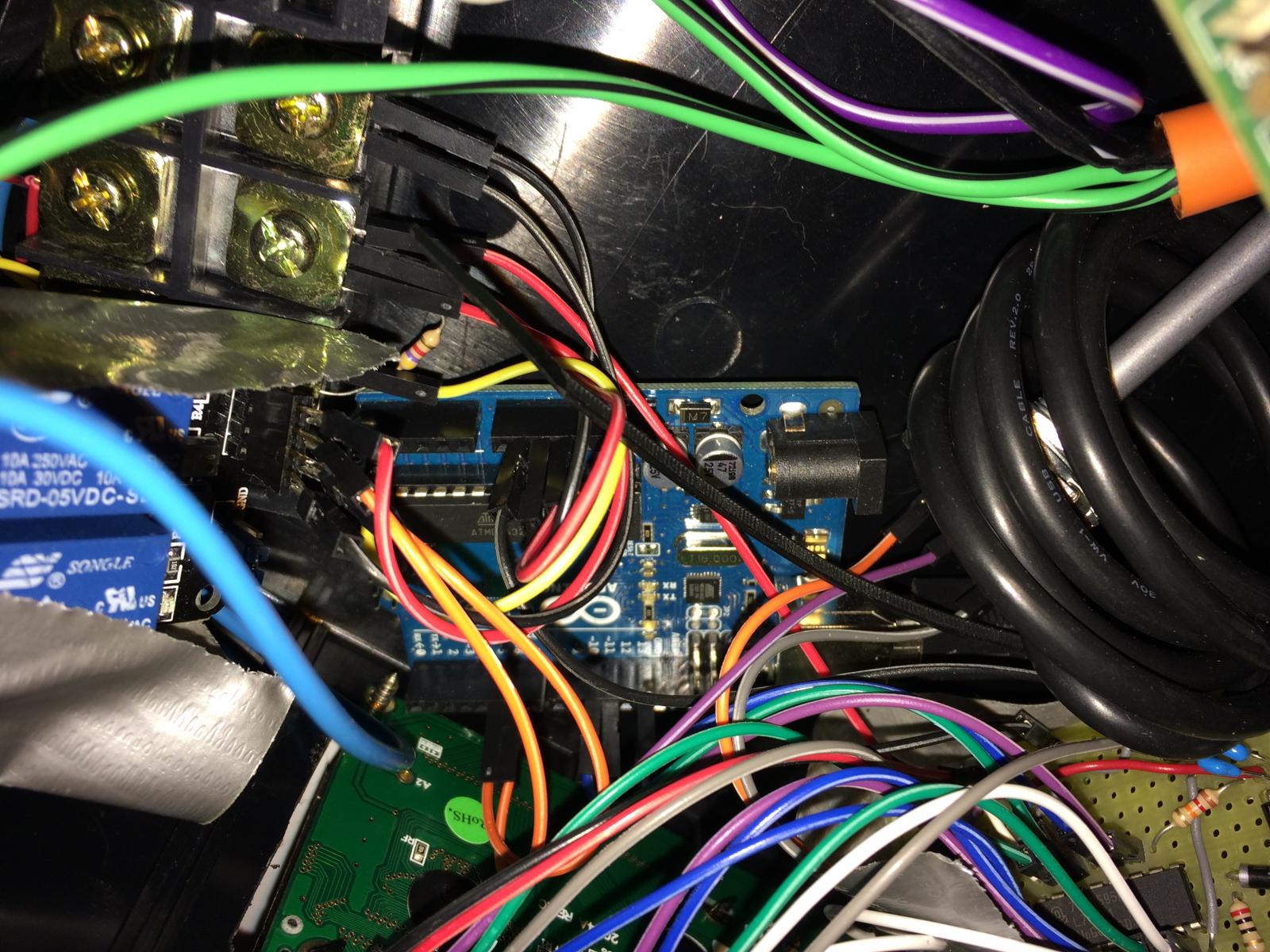

I picked up a chunk that was wide enough to insert the guts of a $2 eBay 9V 1A wart, shrunk it snug, and hard-wired it inside my wee minion case.

The volumetric difference is dramatic - I literally could not have added the LCDs to my minions if I kept the wall wart cases intact.

You could use electrical tape as well - it's not like there's a lot of heat going on inside one of these things, so it should stay wrapped...

Cheers!

I'll keep that in mind. Depending on the enclosure, I thought of using the casing, but that sounds like a better solution.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)