Oh! Didn't realize that. I guess since I was connecting to the headers I did not even think there were pull-ups there. No reason there could not be of course. That's what I get for thinking.Not true. We are using the pull ups. There are two resistors in day_trippr's layout that are connected to the i/o pins 7 and 8.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How To: BrewPi LCD Add-On

- Thread starter day_trippr

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The way the ones we have now are set up, there are four connections:

I see the ones you listed (most of them out there) have five connections:

- ROT A

- PB

- GND

- ROT B

How does one "adapt" five connections to the four in the wiring diagrams we are using now?

- CLK

- DT

- SW

- +

- GND

I don't believe we are using pull-ups on the Arduino ... I suppose the Arduino has that capability as well?

Yes, Arduino has internal pull-ups that can be programmatically turned on or off.

The rotary encoder is literally just a switch, and it doesn't matter how it is labelled.

To use them with the Arduino shield I would either remove the pull-ups on the shield and connect CLK and DT to ROT A and ROT B, SW to PB, GND to GND, and + to +5V.

Or remove the pull-ups on the switch PCB and wire it the same but don't connect +.

Probably wiring it the first way would work even without removing the pull-ups.

Sorry, I forgot that you were able to get everything working without an Arduous and were going directly to the Pi.

There are internal pull-ups in the Arduino too. You can save a resistor, and the board space, and the wiring. That's maybe 1 cent right there. When you make a million of them the savings add up.

Bigdaddyale

Well-Known Member

I just got an email saying the boards shipped.BrewPi Shield batch run #2

Ubermick = 3

Cadibrewer = 2

SHB = 4

user 40839

Well-Known Member

- Joined

- Jul 13, 2009

- Messages

- 1,176

- Reaction score

- 86

I just got an email saying the boards shipped.

From China though? So they'll be here... sometime in 2032?

(Thanks again for organizing)

Bigdaddyale

Well-Known Member

That was fast! The boards arrived today. Build instructions and BOM are located here.From China though? So they'll be here... sometime in 2032?

(Thanks again for organizing)

http://diybrewpi.wikia.com/wiki/BrewPi_Shield

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

user 40839

Well-Known Member

- Joined

- Jul 13, 2009

- Messages

- 1,176

- Reaction score

- 86

That was fast! The boards arrived today. Build instructions and BOM are located here.

http://diybrewpi.wikia.com/wiki/BrewPi_Shield

Outstanding job, sir. Got the payment off to you, and looking forward to getting to work.

CadiBrewer

Well-Known Member

How hard would it be to change the design of the board so it will interface directly with a nano?

It would mean a complete redesign but obviously it could be done. My question would be why use the nano with a shield, because you are going to lose the advantage of the small form factor. You'll save a couple of bucks over the Uno but you'll end up with a shield bigger than the nano itself due to all of the component headers. Someone smarter than I could definitely shrink the board to a smaller size, but I doubt you'd get it close to the nano in size.

That being said, if I were to mock up a board, I'd make it so the nano slots into the pcb and sits right on top with all of the component headers around it. You could come up with a pretty cool layout...

Bigdaddyale

Well-Known Member

2nd run shields are in the mail with a 11/25/16 delivery date.

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

It would mean a complete redesign but obviously it could be done. My question would be why use the nano with a shield, because you are going to lose the advantage of the small form factor. You'll save a couple of bucks over the Uno but you'll end up with a shield bigger than the nano itself due to all of the component headers. Someone smarter than I could definitely shrink the board to a smaller size, but I doubt you'd get it close to the nano in size.

That being said, if I were to mock up a board, I'd make it so the nano slots into the pcb and sits right on top with all of the component headers around it. You could come up with a pretty cool layout...

Because you could design it so it all fits behind the lcd and it'll be an all-in-one form factor. a micro could also be used but they are a bit more of a pain to program and not that much smaller than the nano

Bigdaddyale

Well-Known Member

Looks like you guys should all receive the boards today.2nd run shields are in the mail with a 11/25/16 delivery date.

user 40839

Well-Known Member

- Joined

- Jul 13, 2009

- Messages

- 1,176

- Reaction score

- 86

Looks like you guys should all receive the boards today.

Damn, you're on top of it like a midget up a ladder.

My boards are in my dirty little hands, and will start solderin' 'em up as soon as I finish getting the components. (I noticed the Mouser BOM got snipped, and finding the right replacements is NOT that easy.)

Thanks a million for organizing the boards sir! I look forward to having these puppies controlling my shiny new SS Brewtech BME Conicals. Next step, glycol chiller!

IF anyone is having trouble locating the PFETs (Mouser was out when I ordered 3 months ago), shoot me a PM. I have about 45 of those guys and I'll snail mail them to you at $0.00. Limit to 1+ your requirements. i.e. you need 2 I'll send you 3.

If anyone would like to get in on a group buy, I would like to order some boards for myself. If I can get 8 or so other boards spoken for, I would be glad to order these and ship them out like BigDaddyAle has done.

Bigdaddyale

Well-Known Member

Just FYI If you do another run You should do it soon. They shut down production at the PCB plant for Chinese New Year in Feb and it could double the time it takes to receive the boardsIf anyone would like to get in on a group buy, I would like to order some boards for myself. If I can get 8 or so other boards spoken for, I would be glad to order these and ship them out like BigDaddyAle has done.

Just FYI If you do another run You should do it soon. They shut down production at the PCB plant for Chinese New Year in Feb and it could double the time it takes to receive the boards

Thanks for the heads up.

I placed the order today so anyone interested in some boards, let me know.

Additionally for those that need to buy the components, here is my project from Mouser with everything except the 4K7ohm resistor.

http://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=888022ec5b

Bigdaddyale

Well-Known Member

I would go with the male header pins like Day-Tripper suggested in this post. post https://www.homebrewtalk.com/showpost.php?p=7755676&postcount=684Thanks for the heads up.

I placed the order today so anyone interested in some boards, let me know.

Additionally for those that need to buy the components, here is my project from Mouser with everything except the 4K7ohm resistor.

http://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=8b8afcac2b

I would go with the male header pins like Day-Tripper suggested in this post. post https://www.homebrewtalk.com/showpost.php?p=7755676&postcount=684

Like these? http://www.mouser.com/ProductDetail...EpiMZZMs%2bGHln7q6pm66B2%2bBauJgnZYnPM8Ywg2Y=

Bigdaddyale

Well-Known Member

Have you tested your DS18B20 sensors to see if they are running in non paresitic mode ? There was a bunch of us who got the wrong DS18B20 sensors from the factory.There is a sketch you can run to test them some where in this thread.https://www.homebrewtalk.com/showpost.php?p=7556259&postcount=5416hello all, could you please help?

i hav made the shield with instruction of the 1st page everything looks good but the temp sensors does not recognized from the brewpi!!!

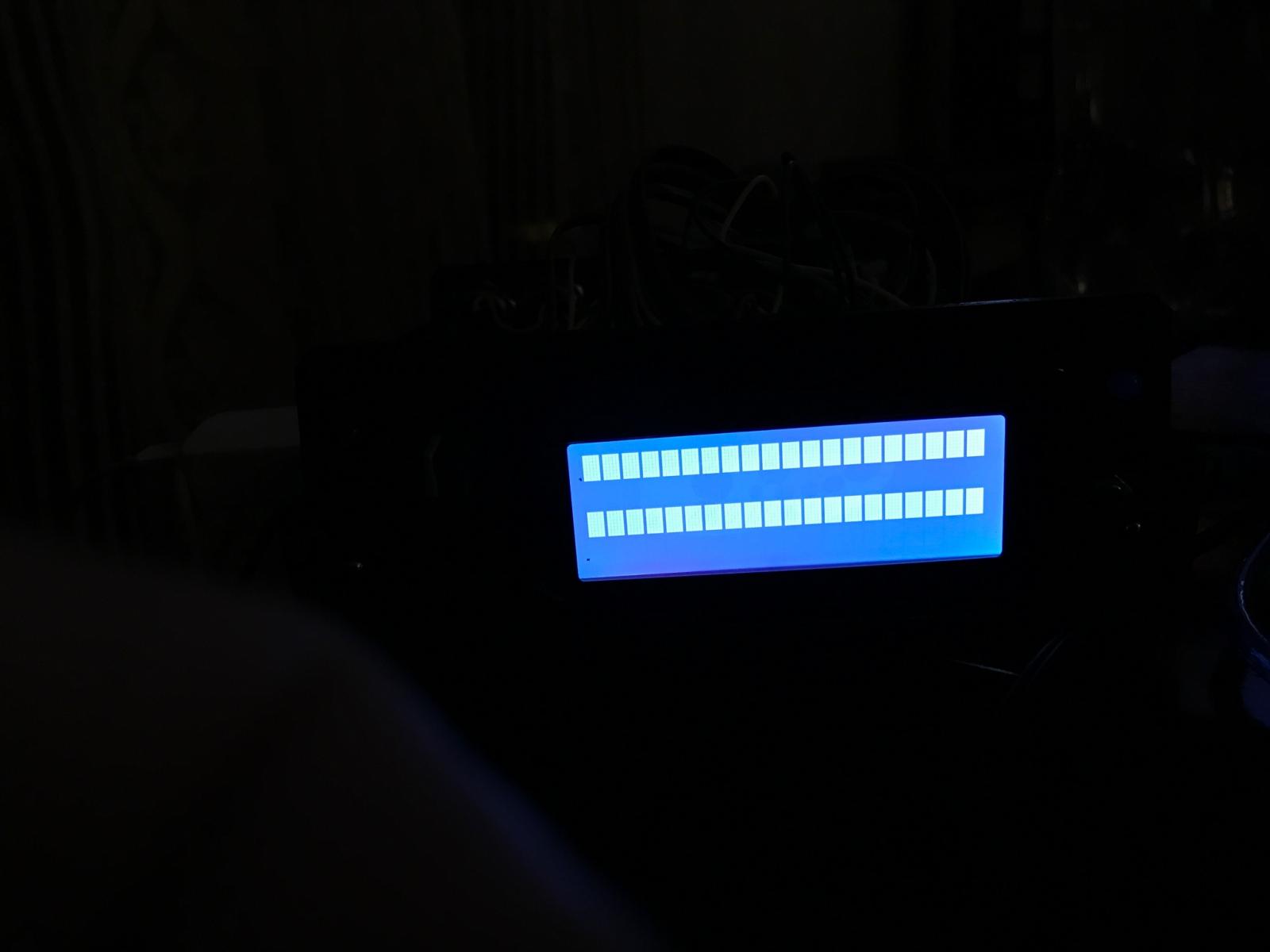

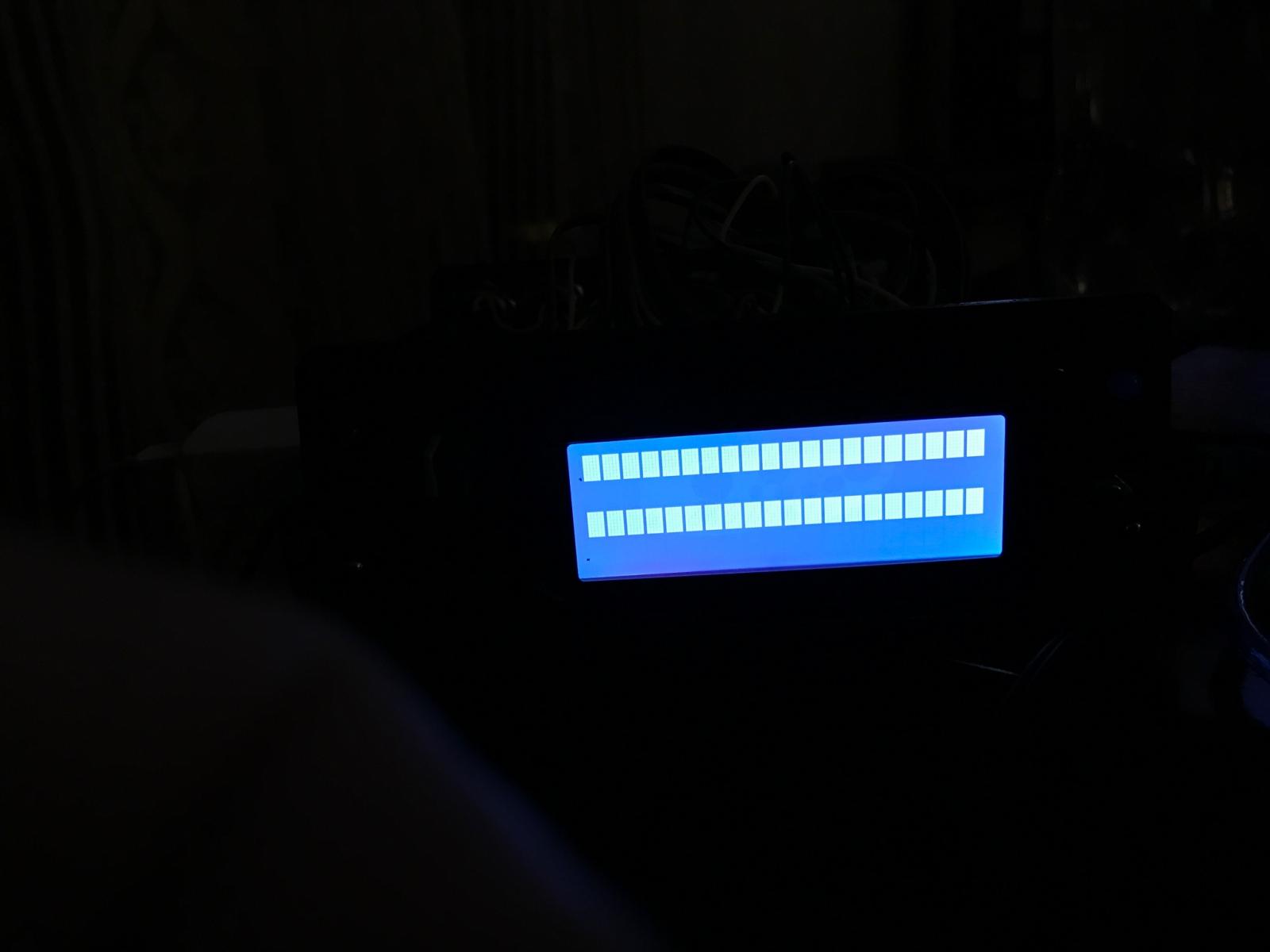

finally the sensors recognized my mistake was on a pin i have double and triple check the pins the problem now is on the screen which shows only 2 lines!! the same thing shown even if itry to connect it via breadboard!!!

That state is where the LCD internal power-up is complete.

It's waiting for a command from the Arduino.

Start with power and ground connections to the shift register, then trace the three inputs from the Arduino, the pull-up on the CLR pin (10) and the grounded OEn pin (13) then the outputs from the shift register to the LCD.

Somewhere there's a miswire...

Cheers!

It's waiting for a command from the Arduino.

Start with power and ground connections to the shift register, then trace the three inputs from the Arduino, the pull-up on the CLR pin (10) and the grounded OEn pin (13) then the outputs from the shift register to the LCD.

Somewhere there's a miswire...

Cheers!

There's also the contrast pot which may be the case ... was with mine.That state is where the LCD internal power-up is complete.

It's waiting for a command from the Arduino.

Start with power and ground connections to the shift register, then trace the three inputs from the Arduino, the pull-up on the CLR pin (10) and the grounded OEn pin (13) then the outputs from the shift register to the LCD.

Somewhere there's a miswire...

Cheers!

There's also the contrast pot which may be the case ... was with mine.

I'm betting you weren't looking at the alternating solid row pattern at the time...

Cheers!

If you power relay #2 from the normally closed side of relay #1, you save a wire nut (save space!) and you prevent both of them from ever coming on at the same time through software or hardware failure.Long as I'm here: I'm reposting this image as the original had an error (B-side NC and NO pin wiring was swapped) and the first post of the corrected version (this one) is buried somewhere in the thread.

I have check all the wires also with the diagram!! i have create also the breadboard but i have the same issue...

i think that is failure of the LCD .....

Did you try adjusting the contrast potentiometer?

When I had that issue with my LCD, I had the connections reversed (pin 1 on 16 and vice-versa).

Finally it works!!!!!!!

i have change the lcd screen with a new one and it works!!! now the only thing that remains is to read how i will program the PID and etc in the brewpi GUI

i have change the lcd screen with a new one and it works!!! now the only thing that remains is to read how i will program the PID and etc in the brewpi GUI  one more question ... if i want to connect the door switch in order to see "open door" alarm in the screen where i should connect it?

one more question ... if i want to connect the door switch in order to see "open door" alarm in the screen where i should connect it?

Finally it works!!!!!!!

i have change the lcd screen with a new one and it works!!! now the only thing that remains is to read how i will program the PID and etc in the brewpi GUI

one more question ... if i want to connect the door switch in order to see "open door" alarm in the screen where i should connect it?

Congratulations!

The door switch is pin 4 to ground and generally set up as "inverted."

Similar threads

- Replies

- 12

- Views

- 4K

- Replies

- 11

- Views

- 2K