I just got a Kegco 3 roller mill and I’m trying to get my crush set up. Not sure I can trust the numbers etched on the case.

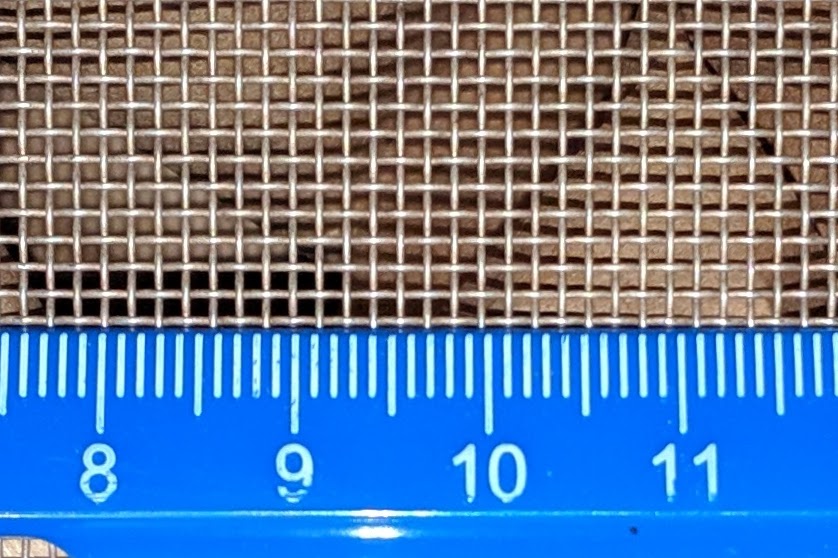

This is a sample with the gap set to about .040, judged by sticking the plastic ruler pictured into the rollers. (Per calipers, it is .040”, but using it as a guide gives me a smaller gap according to the numbers on the mill.)

My goal is to get into the .035-.040 range for a first brew but I could use a sanity check based on the appearance.

My system is e-brew-in-a-basket, with a 1000 micron mesh... so, much more coarse than a bag. I can’t go too fine.

Any thoughts?

This is a sample with the gap set to about .040, judged by sticking the plastic ruler pictured into the rollers. (Per calipers, it is .040”, but using it as a guide gives me a smaller gap according to the numbers on the mill.)

My goal is to get into the .035-.040 range for a first brew but I could use a sanity check based on the appearance.

My system is e-brew-in-a-basket, with a 1000 micron mesh... so, much more coarse than a bag. I can’t go too fine.

Any thoughts?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)