shelly_belly

Someday After A While

I put a solid bung in the better bottle, lay it on it's side and vigorously roll it back and forth a few inches while I count to 60. Then I add the yeast.

osagedr said:Pure O2 through a 0.5 micron stone.

Fermentation is everything--incremental improvements add up to great (not just good) beer.

People who buy a pure O2 system have wasted their money. The majority of the aeration does not come from the bubbles. The bubbles simply mix up the liquid and cause unaerated liquid to continually come to the top and in contact with room air.

I have kept aquariums for years, and my experience comes from that and reading about that topic. Beer is no different than aquarium water when it comes to aeration.

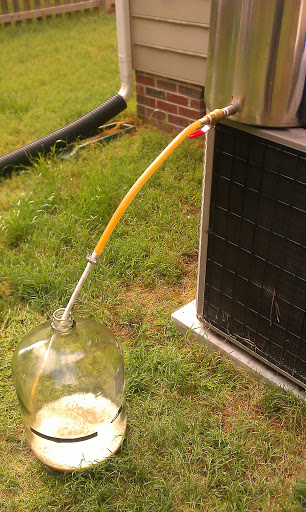

I use the venturi effect mansonsjax mentions earlier.

Here's a youtube video from -TH- that demonstrates it in action.

http://www.youtube.com/watch?v=XqYYbP6Wqfg&feature=channel_page

first 24 hours... Oxygen = good

beyond that... Oxygen = bad

don't shake it doug.

JeepDiver said:Using my Chiller, I move it up and down to quciken the chill, and move it around a lot. It's usually foamy by the time I get through. Never had a problem with stuff fermenting out. I may get some improvment with an O2 kit, but don't see the point right now since things come out good without it.

"It is generally safe to assume that you need at least 10ppm of oxygen. 10ppm will supply adequate oxygen in most situations. Over-oxygenation is generally not a concern as the yeast will use all available oxygen within 3 to 9 hours of pitching and oxygen will come out of solution during that time as well. Under-oxygenation is a much bigger concern."

This is directly from Wyeasts document. Regular air at max, no matter what method you use will only achieve at most, 8ppm. That is why Williams O2 system is important. If you haven't read this document, I highly suggest it. It's well done and easy to understand. I think an earlier poster has a link to it.