I assume you are using std LHBS $8 hydrometer that ranges from 0.980 - 1.120. Consider purchasing lab grade narrow range hydrometers ($30 ea) as a future investment. 2-3 of them will cover the normal brewing ranges. Not absolutely required but the cheapo hydrometers have pretty course accuracy while the lab grade ones will correct to less than a SG point.

There are differences in grain from year to year, variety to variety, and malster to malster that make a difference. Very complex subject and one of the reasons why its challenging to make the same beer back to back every time. There is a science to it but it's not straight forward. This could be a factor as well.

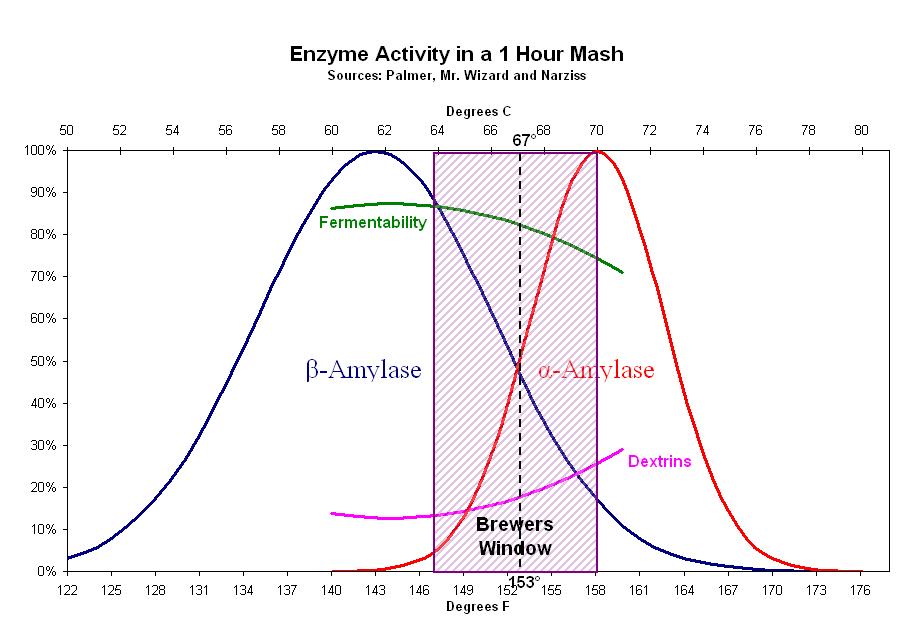

I don't personally have a lot of data about single infusion mashing between 150-160. I typically do a Hockhurz style step mash to get benefits of multiple temperatures. The few times i've done a single infusion mash at like 158 i know i had some cloying beers though.

Dry citrus juice is my preference, but make what you like. To me malt subdues hops so i aim dry as possible for hoppy styles. So for me i step through 144-148-151-162-171 to get great attenuation but still great body and foam.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)