I was in jury duty last week. One of my fellow jurors is in charge of all the Coors and Molson breweries across the U.S.. He and I had a few short discussions on brewery practices, ingredients and procedures.

I know that when I buy hops that it comes enclosed in Nitrogen packets and other times in just refrigerated packets. When I get the hops home, I put it in the refrigerator until I need it….freeze if necessary.

I asked him how they handle hops at the breweries and he told me that they don’t get all excited about its preservation in lots of instances, because in a lot of beers they prefer to get the hops when it is yellow and has been fully exposed to the environment. I asked him why and he told me that their beer recipes are very old and that they want everything the way it used to be.

way back when, they didn’t have refrigeration and the hops always rotted, consequently, they follow suit in this day and age. They want to keep everything the same.

I asked him about corn sugar usage in beers and he told me it is absolutely the best, because it is light corn flavor dextrose and brings out the malt flavors in light colored beers. The problem is that it is cost prohibitive (too expensive). Of course it is a great way to bring up your OD and raise your ABV. The lesser, but still expensive ingredients are corn and rice, but they are also expensive in commercial brewing.

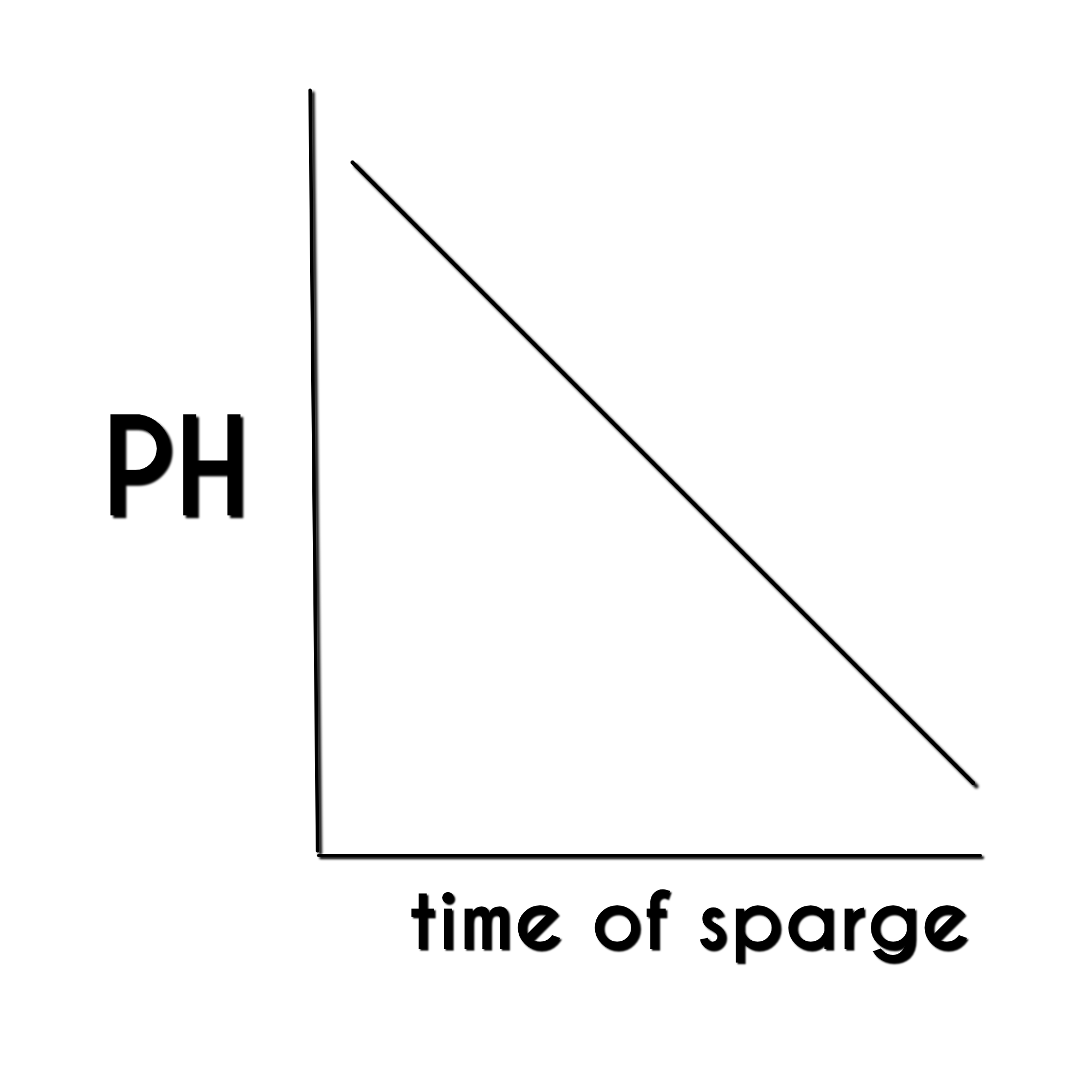

I showed him a couple recipes that I had on my phone. The sparge temperature was listed as 190 - 200 F. He told me to even go 5 degrees hotter. I asked him about tannin release at such high temps and he told me in Home Brewing that should not be an issue, but preferable for a more efficient brew (to get all the sugars).

Personally, I am willing to give all these ideas as a shot (experiment), but I do not claim this to be right, nor will I be responsible for you screwing anything up by using these practices.

I would like to hear your thoughts on these subjects and results if you do try any of them.

I know that when I buy hops that it comes enclosed in Nitrogen packets and other times in just refrigerated packets. When I get the hops home, I put it in the refrigerator until I need it….freeze if necessary.

I asked him how they handle hops at the breweries and he told me that they don’t get all excited about its preservation in lots of instances, because in a lot of beers they prefer to get the hops when it is yellow and has been fully exposed to the environment. I asked him why and he told me that their beer recipes are very old and that they want everything the way it used to be.

way back when, they didn’t have refrigeration and the hops always rotted, consequently, they follow suit in this day and age. They want to keep everything the same.

I asked him about corn sugar usage in beers and he told me it is absolutely the best, because it is light corn flavor dextrose and brings out the malt flavors in light colored beers. The problem is that it is cost prohibitive (too expensive). Of course it is a great way to bring up your OD and raise your ABV. The lesser, but still expensive ingredients are corn and rice, but they are also expensive in commercial brewing.

I showed him a couple recipes that I had on my phone. The sparge temperature was listed as 190 - 200 F. He told me to even go 5 degrees hotter. I asked him about tannin release at such high temps and he told me in Home Brewing that should not be an issue, but preferable for a more efficient brew (to get all the sugars).

Personally, I am willing to give all these ideas as a shot (experiment), but I do not claim this to be right, nor will I be responsible for you screwing anything up by using these practices.

I would like to hear your thoughts on these subjects and results if you do try any of them.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)