Can someone help me understand IBU calculations used by software/websites? My beer recipes are what I feel to be well thought out and designed. I have used BeerSmith and currently have recipes on brewers friend. However, all of my hoppy style beers come out what I taste as severely lacking in hop flavor and aroma. Out of curiosity I entered someone else’s known recipe into brewers friend, specifically it’s the all grain recipe listed on the BYO NEipa style profile. The IBUs listed on the recipe are at 56 but when entered into the brewers friend program IBUs are calculated at 105?!?! What is this?!?! Are all of my recent recipes coming out under-hopped because of a massive over estimation of hop utilization on brewers friend? How is this much variability possible?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hop calculations wayyy off....why? Help

- Thread starter Wyobrew22

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

myndflyte

Well-Known Member

Are you confirming that Brewer's Friend has %AA the same as the BYO recipe?

Smellyglove

Well-Known Member

- Joined

- May 17, 2013

- Messages

- 2,807

- Reaction score

- 807

When it comes to flavor/aroma no software calculates that. When it comes to IBU make sure the hop additions you add are the correct AA, and check how the calculate it.

Can someone help me understand IBU calculations used by software/websites? My beer recipes are what I feel to be well thought out and designed. I have used BeerSmith and currently have recipes on brewers friend. However, all of my hoppy style beers come out what I taste as severely lacking in hop flavor and aroma.

Realize that IBU calculations are designed to estimate isomerization of alpha acids, which is the main component of bitterness in a beer. Hop aroma and flavor involves a whole lot of other stuff, mostly various hop oils.

I did adjust the AA for specific hops in the programs....And just entered into BeerSmith for additional comparison. To summarize: the recipe states 56 IBUs, brewers friend calculates the recipe at 105 IBUs, BeerSmith calculates the recipe at 75 IBUs. I understand aroma and flavor can’t be calculated, I’m just missing a lot of hop character and want to increase it without blowing the IBUs out of proportion, and according to program calculations that’s what will happen with this example recipe. After obtaining an older water report that will get me at least close while waiting on the actual report I am going to add some gypsum to my brewing water but my numbers are very close to the classic listed Pilsen profile.

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

Yes, I did think of that....3 oz of whirlpool hops, and 1 oz at flameout, with 1.5oz FWH and 2 different 3oz dry hop additions. I actually made a similar recipe (based loosely on this one) that will be carbed to taste later today. I am also planning on modifying that recipe and re brewing as I tried a canister style hop spider for the first time and didn’t realize how much the hops would expand and pack that thing.

The calculators are very iffy when it comes to estimating bitterness from flame out and whirlpool additions. Used to be these were small balanced component of the brew but these days, like in your recipe they can be the majority of hops in the brew. None of the available formulas (Rager, Tinseth etc) was designed with this type of brewing in mind.

A lot of this has to do with the complexity of the calculation. After flameout temps are dropping. How fast? Same speed in your system as in mine? Doubt it. Really for big late hop additions trial and error is required. Take good notes. Pay attention to how fast you chill before and during the hop stand. Make adjustment in next batch and repeat.

I hedge my bets on these beers by making sure I’ve got at least 30 calculated IBU from the 60 min addition.

A lot of this has to do with the complexity of the calculation. After flameout temps are dropping. How fast? Same speed in your system as in mine? Doubt it. Really for big late hop additions trial and error is required. Take good notes. Pay attention to how fast you chill before and during the hop stand. Make adjustment in next batch and repeat.

I hedge my bets on these beers by making sure I’ve got at least 30 calculated IBU from the 60 min addition.

I didn't look at the recipe, but 1.5 FWH is pretty big (depending on AA%) for a beer where you want a lot of hop flavor and aroma. For my NEIPAs, I don't do an early boil addition at all. I get all my bitterness from 5 minute, FO and WP additions, where I'm getting a ton of flavor and aroma along with the bitterness. I haven't done a 1.5 oz FWH addition ever, on any of my IPAs back when I was doing early additions for my IPAs.

I use Brewer's Friend for my recipes and it shows the IBU contribution of each hop addition. If I get a number that's off, I start there to see where the IBUs are coming from. Usually I have a WP addition accidentally set as a boil addition.

I use Brewer's Friend for my recipes and it shows the IBU contribution of each hop addition. If I get a number that's off, I start there to see where the IBUs are coming from. Usually I have a WP addition accidentally set as a boil addition.

brew703

Well-Known Member

It's the Wp calculations that are off. I agree w/Eric. I add 30 ibu's at 60 or whenever I end up adding my bittering charge. I just brewed a NEIPA and added my bittering hops at 20. The IBU on Brewers Friend was close to 100 so I just ignore the WP amts and subtract that out. I haven't noticed any overly bitter beers so I know the WP cals are not right. At least for me.

On Experimental Brewing, we interviewed Glenn Tinseth, author of the most widely used hop utilization formula. He had some surprising revelations. First, unless you use the same equipment and chill for the same length of time he did for his research, you won't get the same results. Even more surprising, if you use pellets all bets are off. He only tested with whole hops because back when he did the research pellets were so bad that no one used them! The takeaway is don't worry about the numbers...learn what you like and how it relates to what your software says.

https://www.experimentalbrew.com/experiments/writeups/ibu-lie-kind

https://www.experimentalbrew.com/podcast/episode-32-ibu-lie

https://www.experimentalbrew.com/experiments/writeups/ibu-lie-kind

https://www.experimentalbrew.com/podcast/episode-32-ibu-lie

kylevester

Well-Known Member

What Denny said...

If the bitterness is where you like it with what you've brewed, then keep your additions as you've done in the past. For flavor and aroma, add hops later in the boil or at flame out to help keep that around. And NO OXYGEN post fermentation. That's the biggest killer of hop flavor and aroma in my experience. Once I started flushing kegs by filling with StarSan and pushing out with CO2 and using CO2 to start my beer transfers, my hop forward beers got significantly better and lasted longer.

Also, another reason for the discrepancy could be how the programs are treating FWH. With BeerSmith, when I use FWH, I set it as a 20 minute addition. This seems to be about right as far as the bitterness contribution for me.

If the bitterness is where you like it with what you've brewed, then keep your additions as you've done in the past. For flavor and aroma, add hops later in the boil or at flame out to help keep that around. And NO OXYGEN post fermentation. That's the biggest killer of hop flavor and aroma in my experience. Once I started flushing kegs by filling with StarSan and pushing out with CO2 and using CO2 to start my beer transfers, my hop forward beers got significantly better and lasted longer.

Also, another reason for the discrepancy could be how the programs are treating FWH. With BeerSmith, when I use FWH, I set it as a 20 minute addition. This seems to be about right as far as the bitterness contribution for me.

There was a recent article posted on this site with some calculations that might help you compare your software predictions with real world results... https://www.homebrewtalk.com/formulating-balanced-beer-recipes.html

That resource helps, thanks a lot. I’m just going to pay a lot more attention to how I like the brews to taste rather than the recipes I’m seeing. The neipa i tapped last night was actually pretty decent for a first effort at it and I know exactly how I’m going to improve it, brewing another Sunday.

I have stopped using flameout hops entirely for a couple of reasons.

One, those hops start in boiling water and will contribute a some bitterness before they cool down. How much can be estimated, but it's a pain in the rear. Check out this article, which I only stumbled on yesterday.

https://alchemyoverlord.wordpress.c...-ibu-measurement-especially-for-late-hopping/

Two, I just want flavor and aroma from the late hops anyway.

So, now what I do is figure out a specific whirlpool temperature, chill as fast as possible to that temperature, and then add some hops. I'll even use the PID controller on my electric kettle to keep the temperature where I want it. It's a matter of seconds to punch the buttons, and it's one more variable that I can easily control on repeat brews.

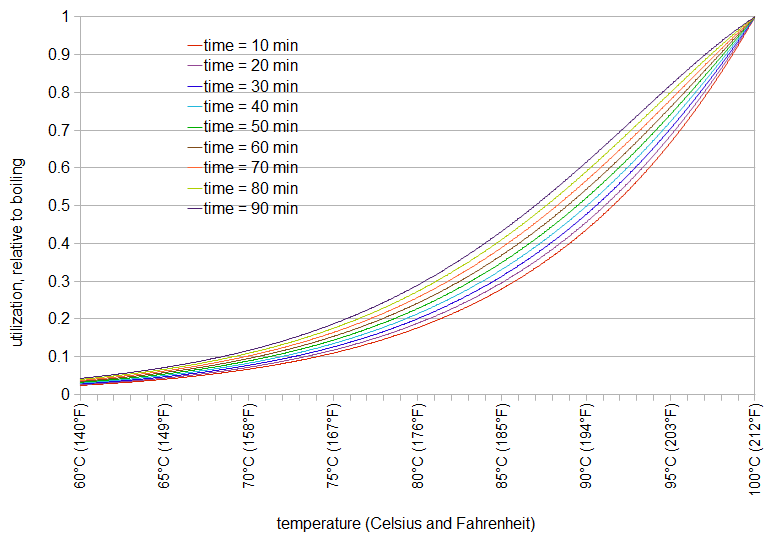

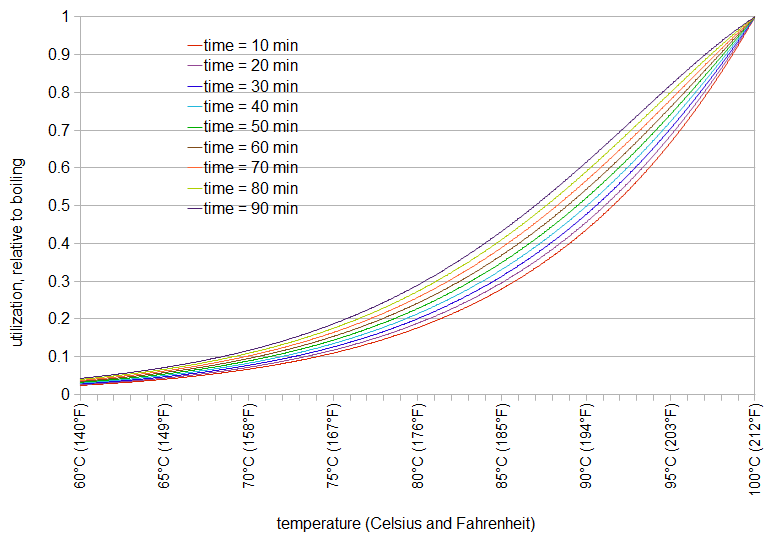

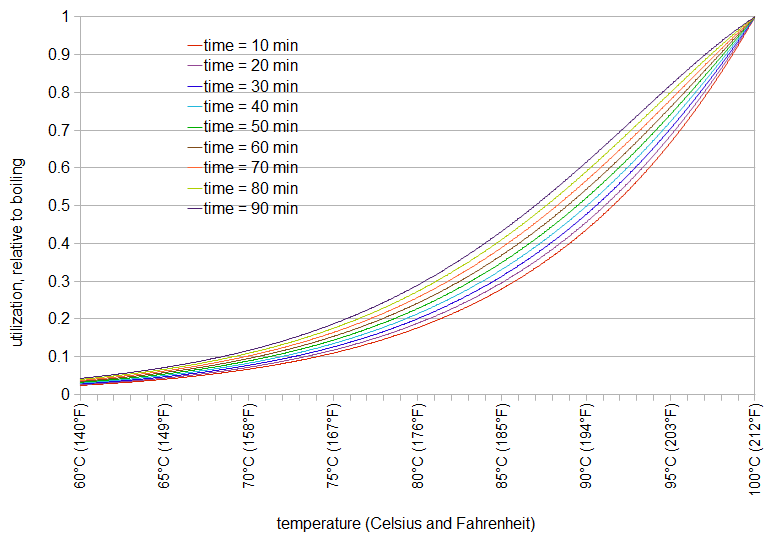

OK, so what is the whirlpool temperature? Well, I also stumbled on another article by the same author that tries to answer the question of how much alpha acid you convert at a given temperature. We know it drops off fast, but how fast?

https://alchemyoverlord.wordpress.com/2016/03/06/an-analysis-of-sub-boiling-hop-utilization/

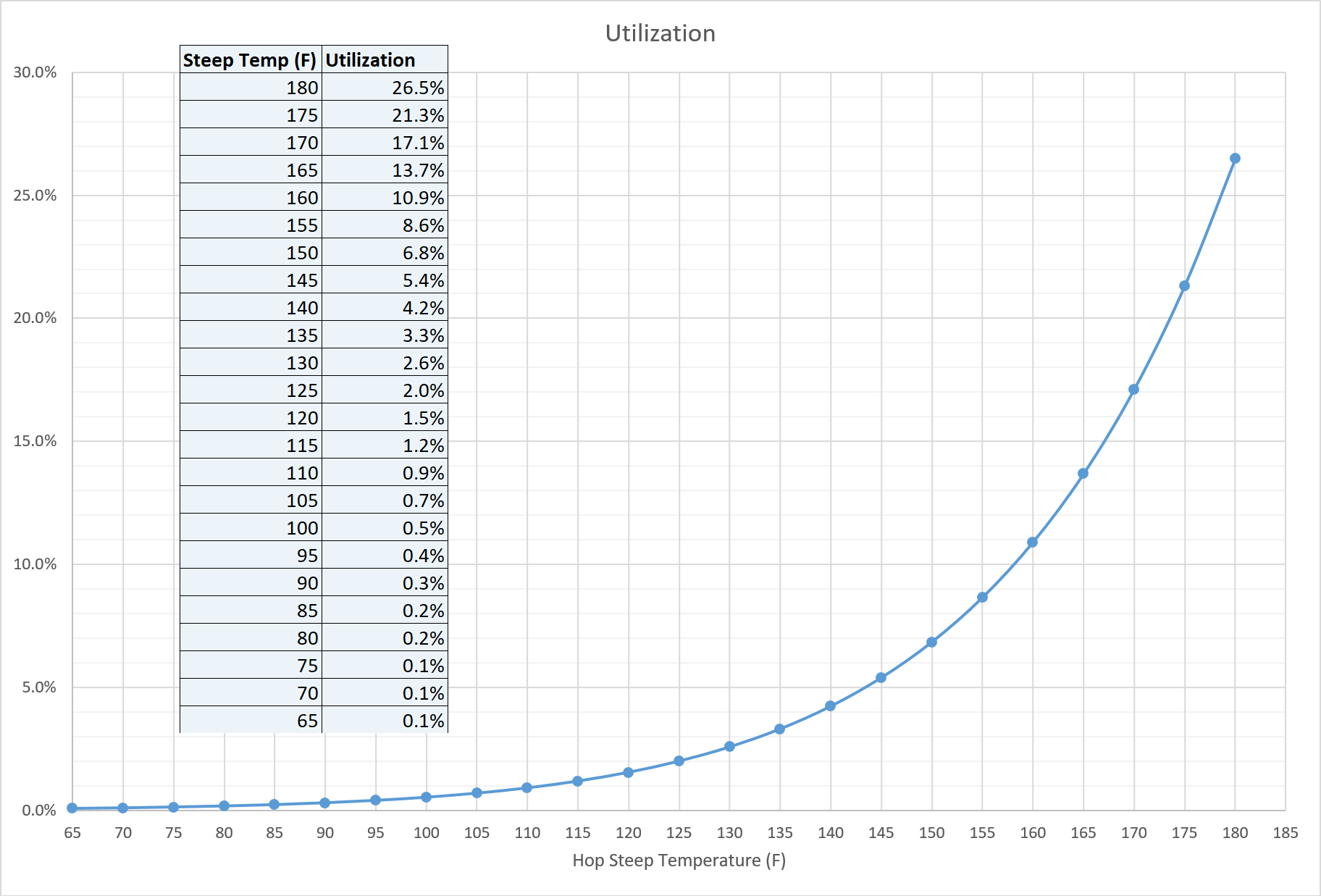

Figure 2 has what I wanted to see:

Before I found this chart, I had been whirlpooling at 165F for 30 minutes. I knew I was adding some bitterness, but with this table I can see that I have been converting about 12% of the whirlpool hop alpha acids this way, as compared to the same time at boil. In my last brew, the 3 oz whirlpool hops that I used added approximately 10 IBU. Next time, I will try a much lower temperature with a similar hop load and see how that tastes.

By the way, once you figure out what your whirlpool protocol is, and what conversion percentage it provides, you can enter that into Beersmith under Options > Bitterness. (The default value is 50%, and Beersmith says this corresponds to 194F, in agreement with the chart.)

The articles above are very clear that there is more to bitterness than alpha acid conversion, so this method still has plenty of errors and approximations. I guess those Magnum hops I added at the start of boil are still isomerizing as the temperature drops, too. But now I feel like I am waving one hand instead of both of them when I try to figure out what whirlpool additions do to my bitterness.

Like @Denny said, it's all a house of cards anyway since the Tinseth equation was built for a different job.

And @kylevester is spot on about oxygen. As soon as I started doing low-oxygen transfers to the keg, my hoppy beers showed an immediate and dramatic improvement. They still fade out over weeks in the keg because I am not religious about the practices, but I have found a happy medium where they taste great for long enough to blow the keg.

One, those hops start in boiling water and will contribute a some bitterness before they cool down. How much can be estimated, but it's a pain in the rear. Check out this article, which I only stumbled on yesterday.

https://alchemyoverlord.wordpress.c...-ibu-measurement-especially-for-late-hopping/

Two, I just want flavor and aroma from the late hops anyway.

So, now what I do is figure out a specific whirlpool temperature, chill as fast as possible to that temperature, and then add some hops. I'll even use the PID controller on my electric kettle to keep the temperature where I want it. It's a matter of seconds to punch the buttons, and it's one more variable that I can easily control on repeat brews.

OK, so what is the whirlpool temperature? Well, I also stumbled on another article by the same author that tries to answer the question of how much alpha acid you convert at a given temperature. We know it drops off fast, but how fast?

https://alchemyoverlord.wordpress.com/2016/03/06/an-analysis-of-sub-boiling-hop-utilization/

Figure 2 has what I wanted to see:

Before I found this chart, I had been whirlpooling at 165F for 30 minutes. I knew I was adding some bitterness, but with this table I can see that I have been converting about 12% of the whirlpool hop alpha acids this way, as compared to the same time at boil. In my last brew, the 3 oz whirlpool hops that I used added approximately 10 IBU. Next time, I will try a much lower temperature with a similar hop load and see how that tastes.

By the way, once you figure out what your whirlpool protocol is, and what conversion percentage it provides, you can enter that into Beersmith under Options > Bitterness. (The default value is 50%, and Beersmith says this corresponds to 194F, in agreement with the chart.)

The articles above are very clear that there is more to bitterness than alpha acid conversion, so this method still has plenty of errors and approximations. I guess those Magnum hops I added at the start of boil are still isomerizing as the temperature drops, too. But now I feel like I am waving one hand instead of both of them when I try to figure out what whirlpool additions do to my bitterness.

Like @Denny said, it's all a house of cards anyway since the Tinseth equation was built for a different job.

And @kylevester is spot on about oxygen. As soon as I started doing low-oxygen transfers to the keg, my hoppy beers showed an immediate and dramatic improvement. They still fade out over weeks in the keg because I am not religious about the practices, but I have found a happy medium where they taste great for long enough to blow the keg.

Thanks for that great input. I will do pretty much the same thing with my next brew. 60min for bittering, half or a third of the remainder at flame out, chill to 75 degrees, throwing in the rest and from there no chill till pitching temp is reached.I have stopped using flameout hops entirely for a couple of reasons.

One, those hops start in boiling water and will contribute a some bitterness before they cool down. How much can be estimated, but it's a pain in the rear. Check out this article, which I only stumbled on yesterday.

https://alchemyoverlord.wordpress.c...-ibu-measurement-especially-for-late-hopping/

Two, I just want flavor and aroma from the late hops anyway.

So, now what I do is figure out a specific whirlpool temperature, chill as fast as possible to that temperature, and then add some hops. I'll even use the PID controller on my electric kettle to keep the temperature where I want it. It's a matter of seconds to punch the buttons, and it's one more variable that I can easily control on repeat brews.

OK, so what is the whirlpool temperature? Well, I also stumbled on another article by the same author that tries to answer the question of how much alpha acid you convert at a given temperature. We know it drops off fast, but how fast?

https://alchemyoverlord.wordpress.com/2016/03/06/an-analysis-of-sub-boiling-hop-utilization/

Figure 2 has what I wanted to see:

Before I found this chart, I had been whirlpooling at 165F for 30 minutes. I knew I was adding some bitterness, but with this table I can see that I have been converting about 12% of the whirlpool hop alpha acids this way, as compared to the same time at boil. In my last brew, the 3 oz whirlpool hops that I used added approximately 10 IBU. Next time, I will try a much lower temperature with a similar hop load and see how that tastes.

By the way, once you figure out what your whirlpool protocol is, and what conversion percentage it provides, you can enter that into Beersmith under Options > Bitterness. (The default value is 50%, and Beersmith says this corresponds to 194F, in agreement with the chart.)

The articles above are very clear that there is more to bitterness than alpha acid conversion, so this method still has plenty of errors and approximations. I guess those Magnum hops I added at the start of boil are still isomerizing as the temperature drops, too. But now I feel like I am waving one hand instead of both of them when I try to figure out what whirlpool additions do to my bitterness.

Like @Denny said, it's all a house of cards anyway since the Tinseth equation was built for a different job.

And @kylevester is spot on about oxygen. As soon as I started doing low-oxygen transfers to the keg, my hoppy beers showed an immediate and dramatic improvement. They still fade out over weeks in the keg because I am not religious about the practices, but I have found a happy medium where they taste great for long enough to blow the keg.

I am not sure if I could get the same "lasting" flavour and Aroma from the 75 degree addition only, that's why I am also adding at flame out. Maybe this is actually not necessary... What do you think? Would only 60 min for bittering and the 75 degree addition for Aroma and flavour be sufficient?

I've been doing hopstands at about 185F - really just because I started out at that temperature and got a good feel for how much bitterness it adds. After reading the articles linked above, I plan to reduce the temperature, using the formulas to estimate IBUs. But I'm a fanatic about infection, so even though hops have antimicrobial properties, I'll probably keep the hop stands at around 170F to get the pasteurization benefit.

I've been experimenting with whirlpool temps for cryo hops. I've tried 185, 160, and 120F. I got the best results by far at 120F.

I got so frustrated with the IBU calculations from the various sites and software, that I ended creating my own spreadsheet that calculates IBUs for each stage separately. The formulas were based on a few days of researching articles on the Internet.

I got so frustrated with the IBU calculations from the various sites and software, that I ended creating my own spreadsheet that calculates IBUs for each stage separately. The formulas were based on a few days of researching articles on the Internet.

That's great, but unless you had the wort analyzed at several points during brewing, you really don't know for certain that it's accurate.

That's great, but unless you had the wort analyzed at several points during brewing, you really don't know for certain that it's accurate.

Very true - my calculations are a best guess based on IBU formula research at different brewing stages. There's been no laboratory analysis of the wort so I'm not making any claims to its accuracy other than it appears close from a sensory perspective. Now with the concept of Alternate Bittering Compounds (ABCs) being thrown around, I'm wondering how long it will be until someone starts adding these calculations to the software!

I am sure we are all just various kinds of wrong, but as long as we have a consistent method and learn how it tastes... That is as good as it's gonna get for now.

Too bad there is no cheap home IBU test, like the little test kits you can get for your aquariums!

Too bad there is no cheap home IBU test, like the little test kits you can get for your aquariums!

I got so frustrated with the IBU calculations from the various sites and software, that I ended creating my own spreadsheet that calculates IBUs for each stage separately.

I hear you. Just today I entered a recipe into BrewersFriend Recipe Designer software and it calculated a Tinseth IBU of 42.9. I then entered the exact same recipe into six other online calculators and got six different results ranging from 40.6 to 50.8! Since the average of all of these calculations is 45, I decided from now on I will just use the BrewersFriend software and add 2 to the result.

TomVA

I am sure we are all just various kinds of wrong, but as long as we have a consistent method and learn how it tastes... That is as good as it's gonna get for now.

Too bad there is no cheap home IBU test, like the little test kits you can get for your aquariums!

This is who I use...http://www.oregonbrewlab.com/homebrewers/ . Also, I'm about to start testing a new device for home use that will give you IBUs, protein, etc.

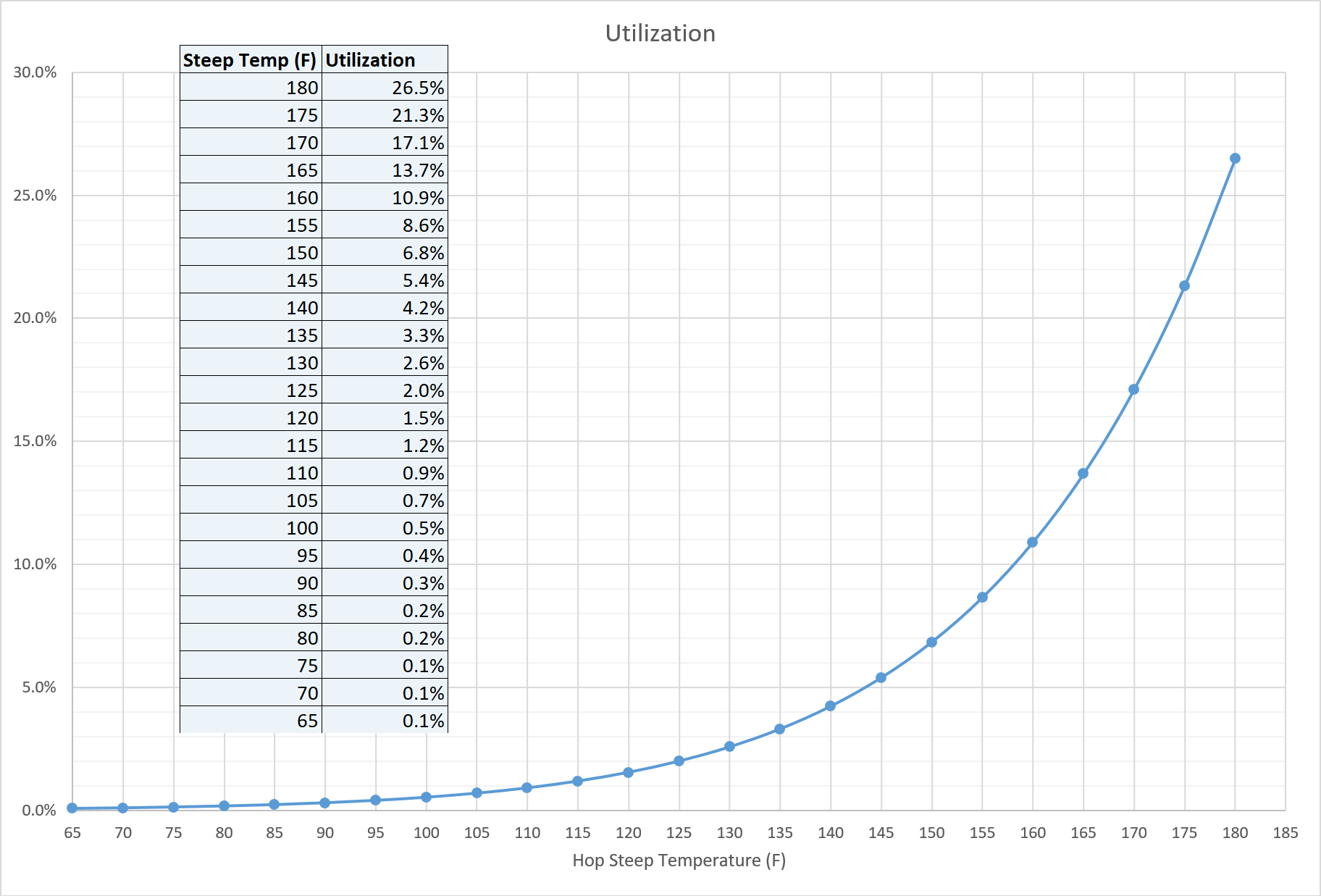

I used the equations in that article to make a hop utilization graph which is easier to read in the low-utilization region. Below is the graph and the table of values, from 180F down to 65F by 5F increments. (direct image link) If anyone wants my spreadsheet file, let me know.

The part of the paper I referenced was this. Note that the assumption is a 40 minute steep, but the author says that temperature is much more important than time.

Next time I whirlpool I am going to try 130F for 30 minutes, for approx 2.5% extra utilization. My last pale ale had a 165F steep step, and while it was tasty and within style guidelines, it was more bitter than I had intended because the steep step added ~11 IBU.

@Denny, looking forward to hearing about that gadget!

The part of the paper I referenced was this. Note that the assumption is a 40 minute steep, but the author says that temperature is much more important than time.

These values of relative utilization are dependent on both time and temperature, although the temperature component has a much larger impact than the time component. We can approximate this as a function of only temperature, by choosing a single steep time to represent the general case, e.g. 40 minutes. We can then fit the relative utilization data to an equation. In this case, a root-mean-squared fitting error of 0.013 can be obtained with the Arrhenius function Urel(T) = 2.39×1011 e-9773/T (where T is temperature in degrees Kelvin). In this case, at 373.15 Kelvin (or 212°F or 100°C), Urel(T) is close to 1.00; at 194°F (90°C), the utilization is half that of boiling.

Next time I whirlpool I am going to try 130F for 30 minutes, for approx 2.5% extra utilization. My last pale ale had a 165F steep step, and while it was tasty and within style guidelines, it was more bitter than I had intended because the steep step added ~11 IBU.

@Denny, looking forward to hearing about that gadget!

I am working on an experiment and communicating with a guy who's already working on it, that shows it's the protein level, not the gravity alone, of the wort that makes a difference to utilization.

That would make perfect sense given the fact that for example the chevallier malt seems to mute malt bitterness, but also leaves higher protein content in the wort. I'll bet @Northern_Brewer might find this interesting.I am working on an experiment and communicating with a guy who's already working on it, that shows it's the protein level, not the gravity alone, of the wort that makes a difference to utilization.

That would make perfect sense given the fact that for example the chevallier malt seems to mute malt bitterness, but also leaves higher protein content in the wort. I'll bet @Northern_Brewer might find this interesting.

Consider this...2 worts of the same gravity, but one has a high % of sugar. In that case the protein content will be vastly different although the gravity is the same.

Next time I whirlpool I am going to try 130F for 30 minutes, for approx 2.5% extra utilization. My last pale ale had a 165F steep step, and while it was tasty and within style guidelines, it was more bitter than I had intended because the steep step added ~11 IBU.

OK I'm not a math guy so forgive me if I'm showing my stupidity here.

Every formula I see for calculating IBU additions in the boil all include the gravity at the start of the boil along with the volume at the start of the boil. But if I'm adding a 5 minute hop addition then my gravity will me much higher, probably close to the ending boil gravity, and the volume will be significantly less than the starting boil volume.

I put a worksheet together that calculates the contributed IBU's based on the volume at the time of the hop addition and the gravity at the time of hop addition and the figures can vary quite a bit over the 'standard' formula used.

Does this make sense or am I just not understanding this?

I think you are correct. The standard way of doing things hand-waves away some important factors. We just don't have a complete toolbox yet. Your approach seems smart to me.

Any value we calculate today is surely wrong... but by using the available tools in a consistent manner I hope to be less wrong than if I just winged it. A consistently somewhat wrong approach will still help me produce tasty beer, and make meaningful and predictable changes to recipes when I want to adjust bitterness.

Any value we calculate today is surely wrong... but by using the available tools in a consistent manner I hope to be less wrong than if I just winged it. A consistently somewhat wrong approach will still help me produce tasty beer, and make meaningful and predictable changes to recipes when I want to adjust bitterness.

Similar threads

- Replies

- 18

- Views

- 2K

Latest posts

-

-

-

-

The Dysfunctional-Palooza Obnoxious Masshole BS Thread

- Latest: Hoppy2bmerry

-

-

-

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)