I have been kinda thinking about this as I have been low on my OG the last few brews. I started using my own mill of which I have the gap set at about a credit card thickness. I am thinking of tightening the crush a bit more to see if this helps. But, I know I don't want to go to tight because I think that will mess up my mash, correct? My other thought is, I have some light DME that I was using to attempt to do a starter with, that failed miserably, but that's another topic. My thought is, pull a sample with 10 mins or so left in the mash and see where I am. If I am low, add a bit of DME to see if I can bring it up. Would that be advisable to do? My last thought, is to increase my mash time by 15 mins and check again to see what I get. Any comments would be appreciated. Rock On!!!!!!!!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hitting my OG

- Thread starter redrocker652002

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

wsmith1625

Well-Known Member

Personally I wouldn't add dme after the mash. It won't hurt anything but it's not that important. On your next batch, you should adjust to compensate for the low gravity. You could grind your grain tighter, add more total grain, or add a dunk sparge. My advice is to tighten your mill gap a bit and see if your numbers pick up. With BIAB there is very little consequence to grinding very fine.

If your using brewing software, you could also leave everything alone and simply lower your efficiency a bit. The software will adjust to your lower efficiency by increasing the grain bill. What is your current efficiency set to?

If your using brewing software, you could also leave everything alone and simply lower your efficiency a bit. The software will adjust to your lower efficiency by increasing the grain bill. What is your current efficiency set to?

Maybe the recipe estimate is off?

Question N° 1: Have you dialed in your recipe software with observed data pulled from multiple batches? Actual grain absorption ratio, etc?

Question N° 2: Are you using lot specific potential numbers for your base grain?

+1 BIAB, crank the mill down. No risk of a stuck sparge. At least one BIABer here does 100% wheat or rye with no rice hulls.

As long as your efficiency is consistent, it can be worked with.

Is your mash gravity low? Or just OG? The former would likely be low conversion efficiency. Fix that. Tighter gap, longer mash, calibrate thermometer, take a look at mash pH. The latter may be low conversion, not enough boil off, or...

Question N° 1: Have you dialed in your recipe software with observed data pulled from multiple batches? Actual grain absorption ratio, etc?

Question N° 2: Are you using lot specific potential numbers for your base grain?

+1 BIAB, crank the mill down. No risk of a stuck sparge. At least one BIABer here does 100% wheat or rye with no rice hulls.

As long as your efficiency is consistent, it can be worked with.

Is your mash gravity low? Or just OG? The former would likely be low conversion efficiency. Fix that. Tighter gap, longer mash, calibrate thermometer, take a look at mash pH. The latter may be low conversion, not enough boil off, or...

My take on adding DME is to not, but it's certainly viable, normal, and etc.

I don't chase a gravity number. I take great care in recording volume and gravity data throughout the making process. By comparing these numbers across batches and throughout a brew, I can find where they 'don't add up' and which numbers are reliable. This has allowed me to find tune my software to the product, not the other way around. By making the software reflect the beer as it is, subsequent beers come out the way I intended with very little effort.

My most recent batch was intended to be 4G VIF @ 1042. It hit 1041 and I just filled 42 bottles. 4G/12oz=42.66

It took me a couple dozen batches to really get my software dialed in, but I'm thrilled with the repeatable results.

I don't chase a gravity number. I take great care in recording volume and gravity data throughout the making process. By comparing these numbers across batches and throughout a brew, I can find where they 'don't add up' and which numbers are reliable. This has allowed me to find tune my software to the product, not the other way around. By making the software reflect the beer as it is, subsequent beers come out the way I intended with very little effort.

My most recent batch was intended to be 4G VIF @ 1042. It hit 1041 and I just filled 42 bottles. 4G/12oz=42.66

It took me a couple dozen batches to really get my software dialed in, but I'm thrilled with the repeatable results.

I use Brewfather and I think I have it set at 75%. I have to look. I was thinking of fooling around with the recipe I just did that I know what my OG was and see where I am. I already dunk sparge, usually for about 15 mins. My boiloff seems high though. I start with a preboil of about 6.75 gallons and end up just above 5. I am still learning all the ins and outs of all grain, so I may be way out of line in my thinking.Personally I wouldn't add dme after the mash. It won't hurt anything but it's not that important. On your next batch, you should adjust to compensate for the low gravity. You could grind your grain tighter, add more total grain, or add a dunk sparge. My advice is to tighten your mill gap a bit and see if your numbers pick up. With BIAB there is very little consequence to grinding very fine.

If your using brewing software, you could also leave everything alone and simply lower your efficiency a bit. The software will adjust to your lower efficiency by increasing the grain bill. What is your current efficiency set to?

Thank you for all the info. I might tighten the mill up a bit and see where I go. I have only done two batches with my own crush, so I am still gathering numbers. I am going to wipe my slate clean so to speak and start really paying attention to my numbers.Maybe the recipe estimate is off?

Question N° 1: Have you dialed in your recipe software with observed data pulled from multiple batches? Actual grain absorption ratio, etc?

Question N° 2: Are you using lot specific potential numbers for your base grain?

+1 BIAB, crank the mill down. No risk of a stuck sparge. At least one BIABer here does 100% wheat or rye with no rice hulls.

As long as your efficiency is consistent, it can be worked with.

Is your mash gravity low? Or just OG? The former would likely be low conversion efficiency. Fix that. Tighter gap, longer mash, calibrate thermometer, take a look at mash pH. The latter may be low conversion, not enough boil off, or...

Answers to questions:

1. Not really. I have been a little lazy with updating software with my actual numbers, that will change next batch and those going forward.

2. I am not sure what you mean by lot specific. I order most of my stuff thru Morebeer.

My mash efficiency has been low as well I think, but like I said, I have been lazy with the numbers. That will change. I need to go thru all my notes and get them organized and maybe create a spreadsheet with my batch numbers on it to compare.

Thank you all for the input, I will keep this thread posted as I get more comfortable with my process.

Last edited:

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

1. Not really. I have been a little lazy with updating software with my actual numbers, that will change next batch and those going forward.

I'd reframe your question then.

Not: Why is my OG low?

But: Why is my actual OG different from the estimate?

2. I am not sure what you mean by lot specific.

It's probably more important for heritage barleys or floor-malted stuff, etc. Basic 2-row is highly regular.

The recipe estimate is only as good as the inputs. If a given malt is typically 81% extract, but that particular lot(bag) of malt is 79% , your OG will take a hit, but it's not a conversion issue. Even at 100% conversion, your actual OG won't hit the number if the software thinks the malt has 81% potential.

wsmith1625

Well-Known Member

I use Beersmith and have my efficiency at 72%. I think it's pretty accurate for my setup. You may want to chase 75% or just drop to 70% and see if you start getting closer numbers. I think I started at 70 and was overshooting my numbers, so I started increasing until I got consistent results at 72%. Maybe not the most scientific method, but it worked for me.I use Brewfather and I think I have it set at 75%. I have to look. I was thinking of fooling around with the recipe I just did that I know what my OG was and see where I am. I already dunk sparge, usually for about 15 mins. My boiloff seems high though. I start with a preboil of about 6.75 gallons and end up just above 5. I am still learning all the ins and outs of all grain, so I may be way out of line in my thinking.

Split out your efficiencies. Once you can visualize conversion, lauter, and mash efficiencies as three separate items, you'll gain the fast track toward dialing in your system.

That's a rather high boil off, while you still come up short on gravity (OG). So yes, you'll need to look at the efficiencies of each step, as @DBhomebrew mentioned.I start with a preboil of about 6.75 gallons and end up just above 5.

It's even worse. When you end up with (only) 5 gallons in your kettle, due to trub left behind, you won't really have 5 gallons going into your fermenter, which is what actually defines batch size.

As said before, with BIAB you can crush very finely as the (fine) mesh is a very good and efficient grist/wort separator.

Also, smaller sized kernels, such as wheat, rye, oat (malt), etc., will benefit from crushing at a tighter gap. I reset the gap on my mill for each, which is a little bit of a hassle, but I'm quite sure you can crush everything, including Barley, at 0.025" instead of 0.034" (credit card).

Oat malt and other such thin kernels may need it tighter though. Flaked goods are fine too, milled at 0.025".

If you have calipers measure the credit card(s), their thickness can vary a little. You can also sand them to the thickness you want.

As was said before it's easy to add a few points that way, or just let it be. I don't think we can taste 5 points missing in a 1.060 target beer, unless maybe when they're next to each other.If I am low, add a bit of DME

And definitely don't add extract to your mash tun, add to your boil kettle at the end. Or even better, dissolve the extract in some hot wort out of your kettle, and add all of that directly to your fermenter. That way 100% of your $$ extract ends up in your beer.

Oh yes there is. My first batch which was expected to have an OG of 1.050 ended up at 1.072. It was terrible having to drink that much stronger beer.With BIAB there is very little consequence to grinding very fine.

I agree that I thought that was a bit high of a boil off as well. My boil was pretty active and maybe a bit over. Not so much rolling but seemed more. I might try reducing the boil intensity, and maybe put a lid or a fan over the boil to catch some of the condensation and run it back into the kettle. Bbeerme said he had a fan setup right above his boil kettle and had it turned on to return some of the condensation back into the kettle. When I tell you this guy is Mr Gadget, I am not joking. He had a re-circulation setup that was a DIY dream. I am going to try and put it together as it had a recirc pump and heater to heat the wort as it went thru. Ooops, very much off topic. LOL. The .025 is going to be a setting for my next brew to see where that gets me. I have a feeler gauge that I used for spark plug gaps so that won't be a problem.That's a rather high boil off, while you still come up short on gravity (OG). So yes, you'll need to look at the efficiencies of each step, as @DBhomebrew mentioned.

It's even worse. When you end up with (only) 5 gallons in your kettle, due to trub left behind, you won't really have 5 gallons going into your fermenter, which is what actually defines batch size.

As said before, with BIAB you can crush very finely as the (fine) mesh is a very good and efficient grist/wort separator.

Also, smaller sized kernels, such as wheat, rye, oat (malt), etc., will benefit from crushing at a tighter gap. I reset the gap on my mill for each, which is a little bit of a hassle, but I'm quite sure you can crush everything, including Barley, at 0.025" instead of 0.034" (credit card).

Oat malt and other such thin kernels may need it tighter though. Flaked goods are fine too, milled at 0.025".

If you have calipers measure the credit card(s), their thickness can vary a little. You can also sand them to the thickness you want.

As far as what went into the fermenter, I might have been a bit off. It was between 5.25 and 5.50 gallons, but again, I was not very diligent in my recordings. That will change. Thanks to all who replied with info, keep it coming. I am taking it all in and learning a ton from all of you. Rock On!!!!!!!!!!

I think the last batch Brewfather estimated the OG at somewhere near 1.055 and I ended up at 1.044 or something like that. I know it was really off. That one is in the fermenter now, and will be either kegged or bottled this weekend. So we shall see.As was said before it's easy to add a few points that way, or just let it be. I don't think we can taste 5 points missing in a 1.060 target beer, unless maybe when they're next to each other.

And definitely don't add extract to your mash tun, add to your boil kettle at the end. Or even better, dissolve the extract in some hot wort out of your kettle, and add all of that directly to your fermenter. That way 100% of your $$ extract ends up in your beer.

Now that is a problem I don't think I would mind having. LOL. Rock On!!!!!!!Oh yes there is. My first batch which was expected to have an OG of 1.050 ended up at 1.072. It was terrible having to drink that much stronger beer.

To reinforce your point I biab and have my mill set at .022" and use that for everything.That's a rather high boil off, while you still come up short on gravity (OG). So yes, you'll need to look at the efficiencies of each step, as @DBhomebrew mentioned.

It's even worse. When you end up with (only) 5 gallons in your kettle, due to trub left behind, you won't really have 5 gallons going into your fermenter, which is what actually defines batch size.

As said before, with BIAB you can crush very finely as the (fine) mesh is a very good and efficient grist/wort separator.

Also, smaller sized kernels, such as wheat, rye, oat (malt), etc., will benefit from crushing at a tighter gap. I reset the gap on my mill for each, which is a little bit of a hassle, but I'm quite sure you can crush everything, including Barley, at 0.025" instead of 0.034" (credit card).

Oat malt and other such thin kernels may need it tighter though. Flaked goods are fine too, milled at 0.025".

If you have calipers measure the credit card(s), their thickness can vary a little. You can also sand them to the thickness you want.

hotbeer

Opinionated Newb

- Joined

- Mar 10, 2021

- Messages

- 3,090

- Reaction score

- 2,809

All the advice above is good advice. I was just wondering why you think changing your mills gap is going to mess up your mash?

At most you might find your bag takes longer to drain or perhaps the mesh is loose and lets some of the finer ground stuff out into your wort. But all that will do is become trub on the bottom of the FV later. So no biggie.

Of course I'm just assuming you are BIAB. So if you are doing a more traditional mash, then yes you might have to use more rice hulls and do other stuff.

At most you might find your bag takes longer to drain or perhaps the mesh is loose and lets some of the finer ground stuff out into your wort. But all that will do is become trub on the bottom of the FV later. So no biggie.

Of course I'm just assuming you are BIAB. So if you are doing a more traditional mash, then yes you might have to use more rice hulls and do other stuff.

I am going to run my mill down to that area on my next brew and see where it takes me. Rock On!!!!!!To reinforce your point I biab and have my mill set at .022" and use that for everything.

My thought is, finer crush, more will be extracted. That was my thought anyway. Seems I am getting info that my crush might have been a bit too coarse, but I guess I am still interested in any input.All the advice above is good advice. I was just wondering why you think changing your mills gap is going to mess up your mash?

At most you might find your bag takes longer to drain or perhaps the mesh is loose and lets some of the finer ground stuff out into your wort. But all that will do is become trub on the bottom of the FV later. So no biggie.

Of course I'm just assuming you are BIAB. So if you are doing a more traditional mash, then yes you might have to use more rice hulls and do other stuff.

Adding DME (late in the process as @IslandLizard suggests) makes sense to fix a batch that isn't where you want it to be.

But for future batches, it's better to adjust your process and grain bill so you achieve your desired result.

The software will accurately predict the OG only if you measure what your process and equipment achieves and then give it that information. As software makers have long said, "garbage in, garbage out."

But for future batches, it's better to adjust your process and grain bill so you achieve your desired result.

The software will accurately predict the OG only if you measure what your process and equipment achieves and then give it that information. As software makers have long said, "garbage in, garbage out."

hotbeer

Opinionated Newb

- Joined

- Mar 10, 2021

- Messages

- 3,090

- Reaction score

- 2,809

Well if you are not hitting the number you want to hit for OG, then it's seems like you'd want to extract more. If you routinely are under the value specified for the OG by your recipe software, then you need to adjust the efficiency values to match what you are getting in real life. And then you'll see that in order to get the beer to the proper OG that you'll have to either increase the fermentable ingredients beforehand or add some DME or even just sugar, but sugar probably will ferment out differently enough to leave you with a different taste than what just wort will.My thought is, finer crush, more will be extracted. That was my thought anyway. Seems I am getting info that my crush might have been a bit too coarse, but I guess I am still interested in any input.

Milling your grain finer might have you hitting the efficiencies that the recipe is expecting you to hit. Then you won't have to increase the fermentable ingredients or add DME or sugar.

If you are already getting all that you can from your fermentable ingredients and are still missing your OG, then something is wrong somewhere. Probably in the volume of the water you are left with as opposed to what was expected.

If you are only getting about 60% efficiency, then it can be improved if you want. But it's not like a failing grade on your report card that many seem to think of it as. It just means you must use more fermentable ingredients to get the OG that is desired. And account for that by adjusting the stuff in your recipe software to match what you are actually doing and getting.

Conversion efficiency and lauter (wort separation) efficiency are two independent items, but mash efficiency = conversion efficiency * lauter efficiency. Mash efficiency is a composite efficiency. If you maximize conversion efficiency and lauter efficiency, mash efficiency will also be maximized.Split out your efficiencies. Once you can visualize conversion, lauter, and mash efficiencies as three separate items, you'll gain the fast track toward dialing in your system.

If you are recipe building based on brewhouse efficiency, then you also need to worry about transfer efficiency, which equals volume in fermenter / post-boil volume. Brewhouse efficiency then becomes mash efficiency * transfer efficiency = conversion efficiency * lauter efficiency * transfer efficiency. Notice that boiling does not affect efficiency whatsoever (unless you have a significant boil-over or spill a lot during boiling.)

@redrocker652002 : Low OG is very often due to low conversion efficiency (which makes mash and brewhouse efficiencies low.) This is especially likely in your case since you are doing a batch sparge (unless there is something really odd about your sparge process.) Low conversion efficiency almost always comes down to the crush being too coarse for conversion to complete in the allotted time for the mash. Conversion is a two step process, gelatinization followed by starch hydrolysis (chopping up starch into sugar.) Non-gelatinized starch cannot be hydrolyzed, so you need some gelatinization before any hydrolysis can occur. Once you have started gelatinization, hydrolysis can proceed in parallel, but to achieve 100% conversion efficiency, you first have to reach 100% gelatinization of the starch.

Gelatinization starts at the surface of the grits, and proceeds inwards. The larger the grits, the longer they take to completely gelatinize, so coarser crushes need longer mash times to reach 100% conversion efficiency. This is why crushing finer often resolves mash efficiency issues. The other thing you can do is mash longer.

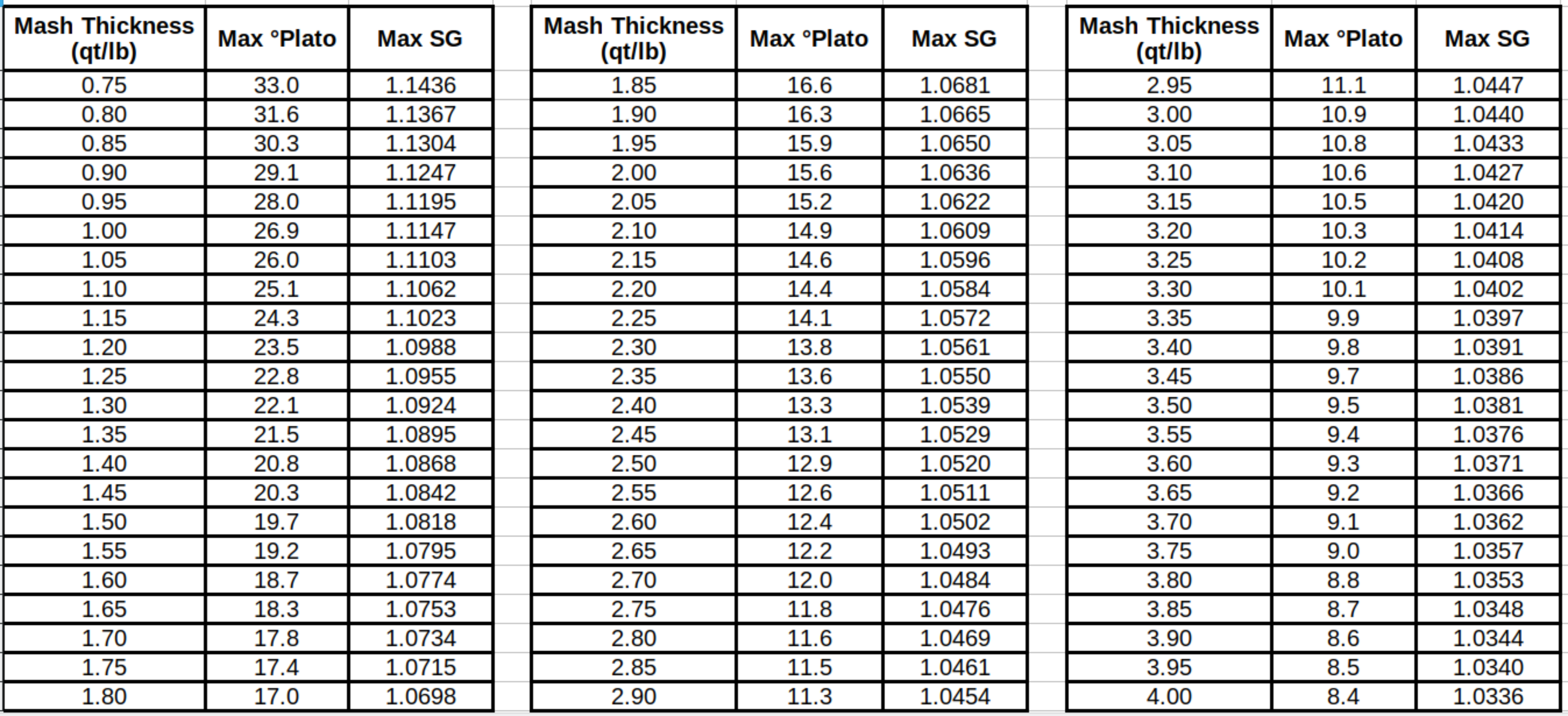

It is relatively easy to quantitatively monitor the progress of conversion during the mash. It turns out that the maximum SG of wort in the mash (after 100% conversion) is determined by three variables only: the total grain weight, the mash thickness (eg. qt / lb of strike water), and the weighted average grain potential. For most reasonable recipes, weighted average grain potential is 80% +/- 1% fine grind dry basis (1.0365 - 1.0375 expressed as SG potential of 1 lb in 1 gal of wort.) So, simply by monitoring the SG of the wort during the mash (after a thorough homogenization of the mash) you can tell what the current conversion efficiency is. Sampling is easier if you have a low sample volume instrument (refractometer or EasyDens.) The chart below shows the maximum wort SG (at 100% conversion) for a range of mash thicknesses and a weight average grain potential of 80% (FGDB.) Your current conversion efficiency is equal to:

Instantaneous conversion efficiency = (Current SG - 1) / (Max SG -1)

If your conversion efficiency is low at the end of whatever mash time you chose, then let it keep going for another 10 - 15 minutes and check the SG again. Continue until you get an acceptable SG or the SG stops increasing from one sample to the next.

Brew on

More great info to digest. Thanks all. I think I am going to start with a finer grind and check my OG at 60, if it isn't what I think it should be, I will go another 15 mins and check again.

I, in the past, have added all my ingredients and weights to Brewfather. The software then tells me how much sparge and strike water I should be using and what my OG and PreBoil numbers should be. I am going to create a spreadsheet or use the journal my wife gave me to start really tracking numbers and see where I am going wrong. In all honesty, I need to get off the idea that I am going to be right on all the numbers. The beer has been good for the most part, so I guess I should not complain. LOL. Thanks to all who have replied, keep it coming. I appreciate all info.

I, in the past, have added all my ingredients and weights to Brewfather. The software then tells me how much sparge and strike water I should be using and what my OG and PreBoil numbers should be. I am going to create a spreadsheet or use the journal my wife gave me to start really tracking numbers and see where I am going wrong. In all honesty, I need to get off the idea that I am going to be right on all the numbers. The beer has been good for the most part, so I guess I should not complain. LOL. Thanks to all who have replied, keep it coming. I appreciate all info.

Grind the grain as fine as you can. Start checking the gravity at 30 minutes, then every 10 after that. A refractometer helps with this as you won't need a big sample (2-3 drops) and won't need to cool it.

I finally have one of those too. LOL.Grind the grain as fine as you can. Start checking the gravity at 30 minutes, then every 10 after that. A refractometer helps with this as you won't need a big sample (2-3 drops) and won't need to cool it.

jambop

Well-Known Member

Well I suppose everyone has a different story to tell about grain crush but I get sometimes in excess of 85% conversion and always more than 80% using a grain gorilla two roller mill set at 1.60 mm . I treat my brew water to generally give an alkalinity of around 25 - 80 ppm and have calcium at around 100-190 ppm for darker beer and for lighter beers have the alkalinity at around 10 ppm and calcium 50-100 ppm of course other anions are set according to style but I only adjust alkalinity and calcium for the mash and only the alkalinity for the spare the other salts are added to the boil phase . A fine crush only really speeds the conversion a fairly rough crush and a 90 min mash will deliver a good conversion and speedy sparge in my experience, too fine a crush is just going to foul up your sparge. I use a Grainfather S40 .I have been kinda thinking about this as I have been low on my OG the last few brews. I started using my own mill of which I have the gap set at about a credit card thickness. I am thinking of tightening the crush a bit more to see if this helps. But, I know I don't want to go to tight because I think that will mess up my mash, correct? My other thought is, I have some light DME that I was using to attempt to do a starter with, that failed miserably, but that's another topic. My thought is, pull a sample with 10 mins or so left in the mash and see where I am. If I am low, add a bit of DME to see if I can bring it up. Would that be advisable to do? My last thought, is to increase my mash time by 15 mins and check again to see what I get. Any comments would be appreciated. Rock On!!!!!!!!!!!

edit

correction mill is actually set at 1.5 mm

Last edited:

Conversion should be >95% if not 100%. With BIAB, a bag in a kettle, you can grind as fine as you are able. My grist has plenty of flour.

jambop

Well-Known Member

Agr

Agreed I should have said I get about 85% or more mashing efficiency. You do not need to crush grain finely to get good conversion that is a myth a fine crush only speeds the conversion and causes sparging problems. The enzymes are inside the grain and the grains only need lightly crushed enough to to break the grain into a few pieces to allow the brew liquor to enter the grain and start the enzymatic process osmosis then draws the sugars into the brew liquor. Crisp maltings in the UK supply commercial brewers in the UK with their Marris Otter malt pre-crushed through a large three roller mill with a spacing of 1.6 mm .Conversion should be >95% if not 100%. With BIAB, a bag in a kettle, you can grind as fine as you are able. My grist has plenty of flour.

Agreed.You do not need to crush grain finely to get good conversion that is a myth a fine crush only speeds the conversion

On some systems. BIAB, a bag in a kettle, has no problems with flour.and causes sparging problems.

Yes.The enzymes are inside the grain and the grains only need lightly crushed enough to to break the grain into a few pieces to allow the brew liquor to enter the grain and start the enzymatic process osmosis then draws the sugars into the brew liquor.

Ok. We're talking BIAB homebrew.Crisp maltings in the UK supply commercial brewers in the UK with their Marris Otter malt pre-crushed through a large three roller mill with a spacing of 1.6 mm .

jambop

Well-Known Member

You can say what you like mate the notion that crushing your grains to powder to get efficiency is total myth and counter productive in terms of time and fuel required to get the same efficiencies using a standard crush no matter what way you brew. Big brewers know what they are doing and what they do is no different to what small brewers can do ... they do not pound their grain to flour.

Is a fine crush required for full conversion? No.

Is a fine crush detrimental (in regards to a bag in a kettle)? No.

BTW, I don't pound my grain to flour either. A mill is much more effective.

Is a fine crush detrimental (in regards to a bag in a kettle)? No.

BTW, I don't pound my grain to flour either. A mill is much more effective.

I'm a 3V brewer nowadays, but two things for what they're worth:notion that crushing your grains to powder to get efficiency is total myth

Many posts here at HBT advocate the similar "myth" that finer grind improves BIAB efficiency. Not all or mostly flour, granted.

Back in the day, I used a primitive bag (mesh bottom, tight-woven sides) and had some stuck mashes. No mill back then - I ground malt in a blender.

Cheers!

Read more threads on HBT suffering from low efficiency or low OG. There are many where the OP comes back and says that finer crush improved their efficiency. The evidence is convincing.You can say what you like mate the notion that crushing your grains to powder to get efficiency is total myth and counter productive in terms of time and fuel required to get the same efficiencies using a standard crush no matter what way you brew. Big brewers know what they are doing and what they do is no different to what small brewers can do ... they do not pound their grain to flour.

Also, are you aware that there are large commercial breweries that crush to powder using a hammer mill, and lauter with a filter press? Alaskan is one.

Brew on

As @doug293cz points out, over 25% of all the beer produced in the world is made using a Mash press and hammer mill.

Here are a few more breweries that use Meura Mash Filters

Here are a few more breweries that use Meura Mash Filters

jambop

Well-Known Member

Aye they do make some poor beers in the USRead more threads on HBT suffering from low efficiency or low OG. There are many where the OP comes back and says that finer crush improved their efficiency. The evidence is convincing.

Also, are you aware that there are large commercial breweries that crush to powder using a hammer mill, and lauter with a filter press? Alaskan is one.

Brew on

As it happens I was brewing today, Jennings Cumberland ale clone, I took a few photographs you can see my crushed Crisp extra pale MO and the results of my labours. I could probably have got more sugars from the mashed grains but I stopped sparging at 1.015 as I do not want to have to boil for more than 90 mins. I am more than happy with the result of the mash and boil lets hope the beer turns out right... never had a failure in 40 years so I am hopeful .

Grain bill was

Crisp MO 4.1 kg

Flaked Barley 0.3 kg

Carafa III 0.05 kg

Hops Challenger cones 40g @90'

EKG 25g cones @15'

Challenger 10 cones FO

Aye they do make some poor beers in the US

As it happens I was brewing today, Jennings Cumberland ale clone, I took a few photographs you can see my crushed Crisp extra pale MO and the results of my labours. I could probably have got more sugars from the mashed grains but I stopped sparging at 1.015 as I do not want to have to boil for more than 90 mins. I am more than happy with the result of the mash and boil lets hope the beer turns out right... never had a failure in 40 years so I am hopeful .

Grain bill was

Crisp MO 4.1 kg

Flaked Barley 0.3 kg

Carafa III 0.05 kg

Hops Challenger cones 40g @90'

EKG 25g cones @15'

Challenger 10 cones FO

View attachment 821374View attachment 821375View attachment 821376

Use of hammer mills and filter presses for brewing started in Europe. Undoubtedly there are poor beers brewed there as well.

Excellent notes, but you don't list strike volume or mash thickness anywhere (that I could see.) Could you provide that info please?

Also, your conversion was only about 87% complete after a 90 minute mash, if we assume that 1.055 at end of mash-out was 100% complete. Info on strike volume or mash thickness will allow checking the validity of the "complete at end of mash-out" assumption.

Brew on

jambop

Well-Known Member

Strike water and so on was on the other side of the page so I could not have them both on the same photograph.

Mash was 2.7L per kilo and strike volume was 20L , should have been 19.89 I just round up, the Grainfather has about 8 L of brew liquor sitting under the grainbasket so for the record the grains are doughed in to around 12L of brew liquor at strike temp and then the recirc pump is turned on and mashed stepped to 90 mins then mash out.

I like the S40 but it takes time to get to know it. For example I do not use the markings on the vessel I weigh my mash and sparge water additions so I know what I have added. However after addition the losses during mashing and boiling complicate matters and estimated have to be made. I estimated I had 29.5L in the vessel post boil and that was a good estimate because I got 26 L in the FV and measured the dregs from the bottom of the boiler at 3 L. Volumes are a problem if you want to be really accurate. I have done several volume checks adding known volumes to the boiler and comparing to the markings but the liquid is always at room temp and the boiler cold neither of these things is true for an actual brew until you have chilled the wort so you have to guess a little bit for anything before the post boil volume.

edit

Just another thing I measure the pH just as a reference my water is treated to give a set alkalinity value for this brew the brew liquor alkalinity was 25 ppm

Also the BH figure is wrong I lost more than I thought BH was 75% I could cut that by saving the dregs in a tall cylinder and letting it settle but to be honest for maybe another two litrres of clear wort I cannot be bothered ... but given the cost of materials maybe I should ?

Mash was 2.7L per kilo and strike volume was 20L , should have been 19.89 I just round up, the Grainfather has about 8 L of brew liquor sitting under the grainbasket so for the record the grains are doughed in to around 12L of brew liquor at strike temp and then the recirc pump is turned on and mashed stepped to 90 mins then mash out.

I like the S40 but it takes time to get to know it. For example I do not use the markings on the vessel I weigh my mash and sparge water additions so I know what I have added. However after addition the losses during mashing and boiling complicate matters and estimated have to be made. I estimated I had 29.5L in the vessel post boil and that was a good estimate because I got 26 L in the FV and measured the dregs from the bottom of the boiler at 3 L. Volumes are a problem if you want to be really accurate. I have done several volume checks adding known volumes to the boiler and comparing to the markings but the liquid is always at room temp and the boiler cold neither of these things is true for an actual brew until you have chilled the wort so you have to guess a little bit for anything before the post boil volume.

edit

Just another thing I measure the pH just as a reference my water is treated to give a set alkalinity value for this brew the brew liquor alkalinity was 25 ppm

Also the BH figure is wrong I lost more than I thought BH was 75% I could cut that by saving the dregs in a tall cylinder and letting it settle but to be honest for maybe another two litrres of clear wort I cannot be bothered ... but given the cost of materials maybe I should ?

Last edited:

I feel more relaxed having let go, somewhat, of my urge to try to get every bit I can into the glass. It still rankles to see sweet wort, and finished beer!, go down the drain, but there are other values besides efficiency.cannot be bothered ... but given the cost of materials maybe I should

jambop

Well-Known Member

Thing is it happens every brew a 5L measuring cylinder is all that is required for two or three more flip tops... I think I will buy one .I feel more relaxed having let go, somewhat, of my urge to try to get every bit I can into the glass. It still rankles to see sweet wort, and finished beer!, go down the drain, but there are other values besides efficiency.

For a strike volume of 20 L and mash bill of 4.45 kg, I get your max mash SG @ 100% conversion as 1.0593. Your measured 1.055 at end of mash-out works out to 92% conversion efficiency. (This is using a rigorous method for calculating efficiency rather than the simple 55 / 59.3 = 92.75%.) I get your mash efficiency at 87.6%. I get a higher mash efficiency than your 84% because I correct for the moisture content of the grain (assumed to be 4%) which effectively decreases your grain bill weight.Strike water and so on was on the other side of the page so I could not have them both on the same photograph.

Mash was 2.7L per kilo and strike volume was 20L , should have been 19.89 I just round up, the Grainfather has about 8 L of brew liquor sitting under the grainbasket so for the record the grains are doughed in to around 12L of brew liquor at strike temp and then the recirc pump is turned on and mashed stepped to 90 mins then mash out.

I like the S40 but it takes time to get to know it. For example I do not use the markings on the vessel I weigh my mash and sparge water additions so I know what I have added. However after addition the losses during mashing and boiling complicate matters and estimated have to be made. I estimated I had 29.5L in the vessel post boil and that was a good estimate because I got 26 L in the FV and measured the dregs from the bottom of the boiler at 3 L. Volumes are a problem if you want to be really accurate. I have done several volume checks adding known volumes to the boiler and comparing to the markings but the liquid is always at room temp and the boiler cold neither of these things is true for an actual brew until you have chilled the wort so you have to guess a little bit for anything before the post boil volume.

edit

Just another thing I measure the pH just as a reference my water is treated to give a set alkalinity value for this brew the brew liquor alkalinity was 25 ppm

Also the BH figure is wrong I lost more than I thought BH was 75% I could cut that by saving the dregs in a tall cylinder and letting it settle but to be honest for maybe another two litrres of clear wort I cannot be bothered ... but given the cost of materials maybe I should ?

So, even with a 100 minute mash (including mash out) you still are not achieving 100% conversion efficiency with your crush. But an 87% mash efficiency is nothing to sneeze at.

Brew on

Similar threads

- Replies

- 5

- Views

- 404

- Replies

- 22

- Views

- 1K

Latest posts

-

-

-

-

-

-

-

-

For Sale SS Brewtech - 7 Gallon Unitank 1.0

- Latest: IslandLizard

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)