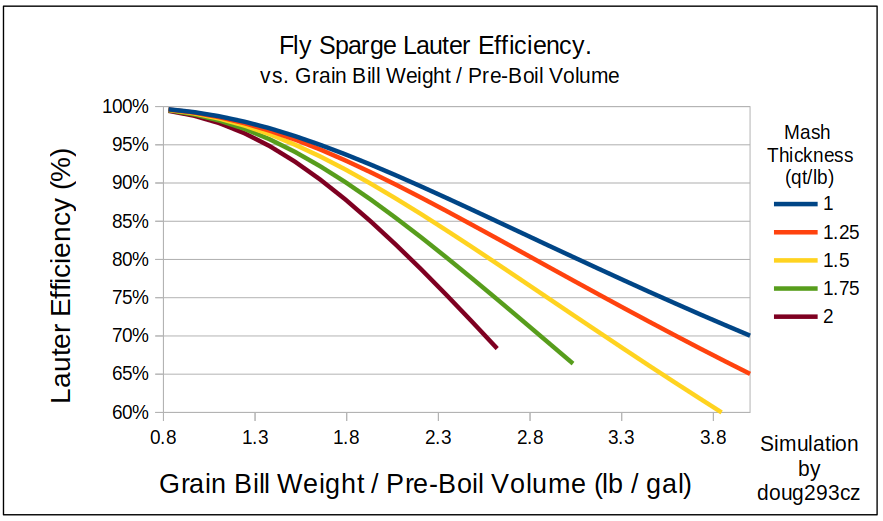

@doug293cz Is there a chart (or formula) out there somewhere that maps out efficiency drop-offs based on how thick the mash is? No rinsing/lautering, just if you soak 1 lb malt in a 2 quarts of water (very thin) at 152F for 60 minutes, you should get be able to get 99% of the theoretically extractable sugars in the malt. And if you soak 1 lb malt in 1 quart of water (very thick) at same temp/time, you can expect to only get 65% of the theoretically extractable sugars...

Something along the lines of:

description | mash thickness | max efficiency

------------+----------------+---------------

very thin | 2.0 | 99%

thin | 1.6 | 95%

average | 1.33 | 90%

thick | 1.2 | 80%

very thick | 1.0 | 65%

If not, it seems like a simple enough experiment to try cheaply at home (small pot and small amount of malt, put it in an oven to keep temp consistent).

Obviously independent variables for different brewers: mill gap, water chemistry, malt choice

*, malt freshness...

Bah, forum software doesn't actually do fixed-width font formatting

*

*Actually, if you're using brewing software for the recipe, it should know the max pts of sugar for each malt, so that's probably not a factor, tho freshness of the malt surely would be...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)