Austin_

Well-Known Member

I have a process similar to Screwy. I recirculate hot PBW water through the system for about 15 minutes. I then dump out the liquid, wipe everything down, and then spray it out. Looks like new.

How’s your cleaning process so far on the ss brewtech kettles? I’ve got a 20 gal, so a little tough to lift and rinse out. I’ve been using PBW and running it thru the pump for 20 min with cold water, but still have buildup and gunk on the coils. Next time I’m goin to heat the water while it’s running thru the cleaning cycle...

I use these to clean my Boilcoils:

https://www.amazon.com/gp/product/B000BAT8PM/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

I cut them in half/quarters and I've only gone through a couple of pads in ~6 months. Just a quick wipe down after cleaning, followed by one more rinse before drying it all off. Worth the $12.

My wife has caught wind of these too and has stolen a bunch for around the house.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I love that brew cart!

Why didn't you ask Dave to get the pickup tube and whirlpool arm for you? He's extremely reasonable with stuff like that.

I agree with ScrewyBrewer that stirring is the key to a better efficiency. Even before I went electric but still doing BIAB, I made sure to stir at least every 12-15 minutes.

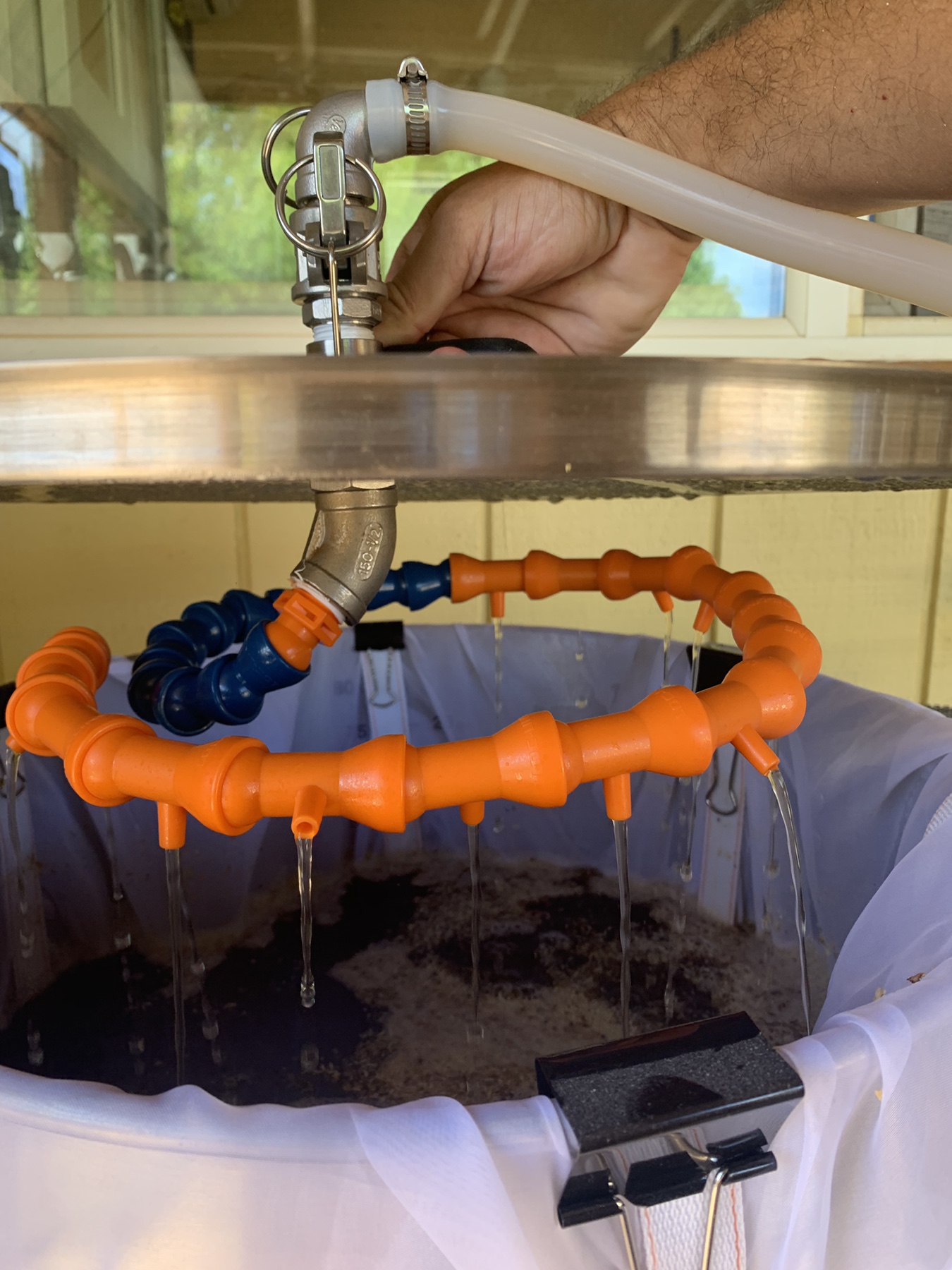

I guess the next logical place to look would be your grain crush and stirring the mash. Our systems don't have arms that turn to agitate and keep the grains from clumping together. I've thought about running the loc-line straight down the center of the grain bed. From the outlet in the top to the bottom of the grain bed. In the hope that the streams of moving wort are enough to agitate the grain bed keeping it nice and loose.

Finally got my whole system together. Wound up getting a pickup tube and whirlpool arm from Brewhardware. I have the 15 gallon 240v version which has the BrewBuilt kettle. The pickup tube fits between two of the coils, touching, but should be fine. I ordered the whirlpool arm with the 18" length and male camlock attachment. Going to test it all tonight and setup my Beersmith equipment profile.

I also put this together last night for a brew cart. It's a beast. Will try to get some pictures of the setup tonight.

Sweet! I love the bar to hold the control unit too!

Good call gonna ditch the basket on next brew and let bag sit directly on coil. Fingers crossed!

Going this route tomorrow. I bought a false bottom from Brew Hardware but by the end of the boil only 1/3 to 1/2 of the coils of my wort chiller will be submerged. And the false bottom is such a tight fit with the boil coil that I can’t easily remove it after the mash.

I can play with my dead space numbers or get a different chiller but I’ll see how this works first.

Did you use the bag that came with the system?

I love both the Brew Bag and Wilser and while I can't swear to it, it appears the Brew Bag gave me some problems with recirculation that the Wilser didn't but I made other changes as well so who knows. I know what I've done lately works for me and that's great.I did. My Wilserbag is too small (only works with the basket). The stock bag worked but I will probably get a new Wilser.

78% is great. What was your mash thickness, do you remember?I ditched the stainless basket and bought another brewbag, one that was made for my 20 gal kettle. Left the controller on during mash so it rested right on coils, no prob. Pump running on low output and recirculated just fine.

End result was 78% efficiency on my 10 gal batch. Couldn’t be happier.

I ditched the stainless basket and bought another brewbag, one that was made for my 20 gal kettle. Left the controller on during mash so it rested right on coils, no prob. Pump running on low output and recirculated just fine.

End result was 78% efficiency on my 10 gal batch. Couldn’t be happier.

Did your heating element have a lot of carbon buildup with the bag resting on it?I ditched the stainless basket and bought another brewbag, one that was made for my 20 gal kettle. Left the controller on during mash so it rested right on coils, no prob. Pump running on low output and recirculated just fine.

End result was 78% efficiency on my 10 gal batch. Couldn’t be happier.

@Beer-lord I've been stuck in the 68-73% efficiency range my past three brew days. I know my grain crush is too fine because after the mash it's been hard getting the wort to drain from the hoisted grain bag. In the meantime I ordered a Bayou Classic false bottom and will ordered the @wilserbrewer Grand Slam package with heavy duty duel ratchet pulleys. It's good to hear you've worked through your earlier issues.For a second I thought about going without the basket then decided, 'if it ain't broke, don't fix it' and glad I did.

I still think mashing in without recirculating for the first 10 minutes or so has made all the difference for me. I'm still right about 80% in efficiency in my pales and 76-78 in my larger beers. I'm ecstatic with that!