Brownyard

Well-Known Member

- Joined

- Aug 19, 2020

- Messages

- 136

- Reaction score

- 64

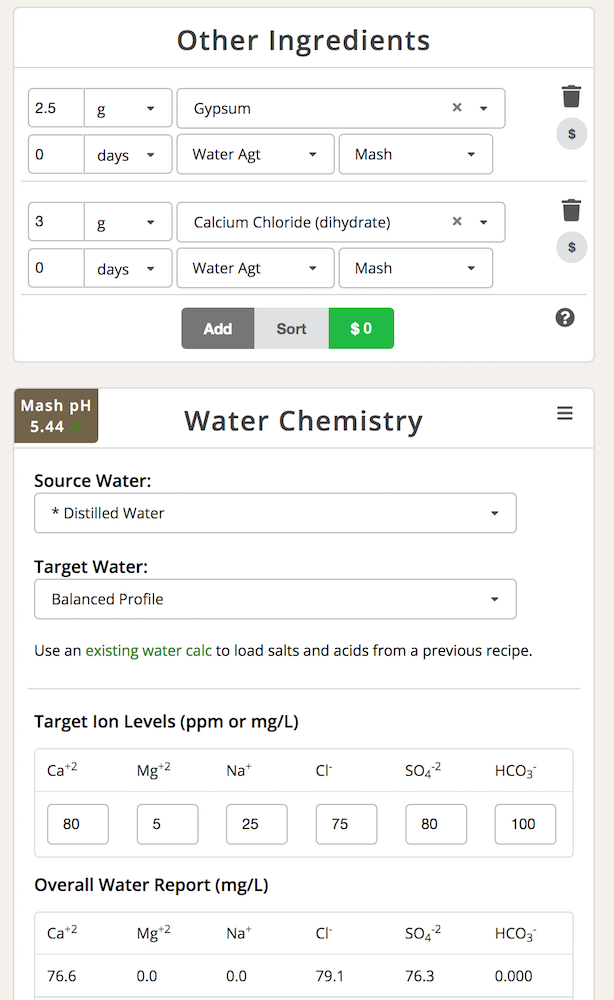

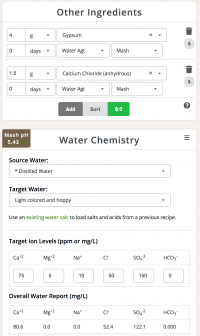

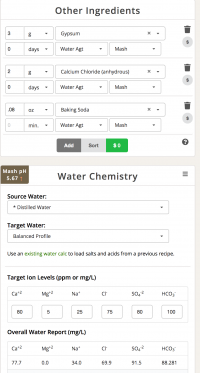

I'm working up a 3 gallon BIAB SMaSH Marris Otter/Citra recipe and will be using distilled or bottled RO Water and am considering Calcium Chloride (1.5 g) and Gypsum (4 g) additions. I'm using Brewer's Friends "Light Colored hoppy" water profile. These additions give me a predicted mash pH of 5.43.

https://www.brewersfriend.com/homebrew/recipe/view/1289274/citra-mo-smash

Anything look glaringly wrong with these adjustments? Should I worry about the sodium and magnesium?

https://www.brewersfriend.com/homebrew/recipe/view/1289274/citra-mo-smash

Anything look glaringly wrong with these adjustments? Should I worry about the sodium and magnesium?

Attachments

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)