So I finally made (in my opinion) a proper NE IPA. I've struggled with this one for a long time and I believe it came down to cold side low oxygen tactics and reducing dry hop time. It was also a total pain in the @$$ and I want to improve my process.

I'd like some good suggestions on how to streamline this low oxygen process aside from buying a bunch of new equipment.

This was my fermentation to packaging process and it was not that fun.

1. Temp controlled bucket fermenter. I applied keg lube to the seal to make sure it was totally air tight. This worked great.

2. Did not cold crash because I did not want to suck in O2 into the bucket,

LODO transferred to a corny keg using a purged corny keg: Beer disconnect to the spigot on the fermenter and gas disconnect to air lock. All the tubing was purged and the beer trades places with the co2 in the keg in a closed system. () This took frikin forever but its pretty easy.

3. Soft crashed to 55 degrees

4. Added entire dry hop bill (6 oz) at one time for 2 days only. Purged keg after addition. Way less grassy herbal flavors.

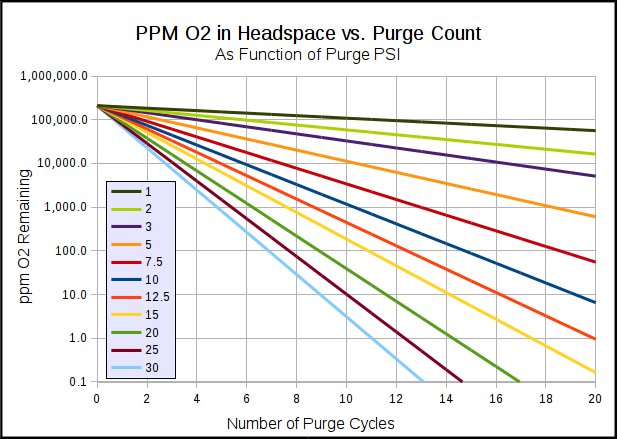

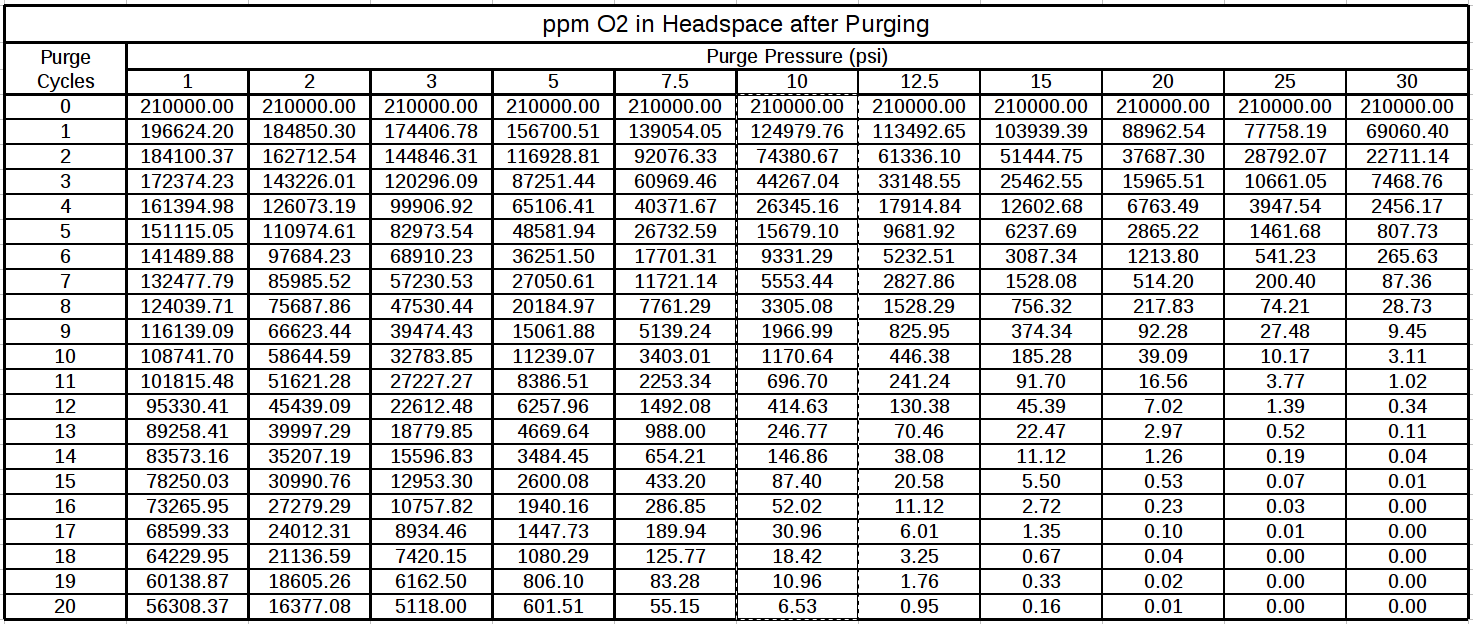

4. Dropped temp to 39 degrees and bumped CO2 to 30 PSI overnight.

5. Keg dip tube clogged and so I racked it over to another keg and it's fine. The keg had a thick layer of yeast that was clogging the dip tube.

What can I do better that still maintains the low oxygen exposure? This didn't go well despite the outcome.

Things that come to mind:

1. Floating pickup tube for the keg.

2. CO2 filled mylar balloon to attach to the air lock for cold crash with bucket and then transfer to a keg.

3. Fermenatsaurus so I never have to transfer it and keep it under pressure.

Thanks in advance!

I'd like some good suggestions on how to streamline this low oxygen process aside from buying a bunch of new equipment.

This was my fermentation to packaging process and it was not that fun.

1. Temp controlled bucket fermenter. I applied keg lube to the seal to make sure it was totally air tight. This worked great.

2. Did not cold crash because I did not want to suck in O2 into the bucket,

LODO transferred to a corny keg using a purged corny keg: Beer disconnect to the spigot on the fermenter and gas disconnect to air lock. All the tubing was purged and the beer trades places with the co2 in the keg in a closed system. () This took frikin forever but its pretty easy.

3. Soft crashed to 55 degrees

4. Added entire dry hop bill (6 oz) at one time for 2 days only. Purged keg after addition. Way less grassy herbal flavors.

4. Dropped temp to 39 degrees and bumped CO2 to 30 PSI overnight.

5. Keg dip tube clogged and so I racked it over to another keg and it's fine. The keg had a thick layer of yeast that was clogging the dip tube.

What can I do better that still maintains the low oxygen exposure? This didn't go well despite the outcome.

Things that come to mind:

1. Floating pickup tube for the keg.

2. CO2 filled mylar balloon to attach to the air lock for cold crash with bucket and then transfer to a keg.

3. Fermenatsaurus so I never have to transfer it and keep it under pressure.

Thanks in advance!

Last edited: