The chocolate, roasted, and black patent smooths out the roasted portion, cuts down on flavor offs. Still the "blond in a black skirt".Most of the recipes I’ve seen only use Maris otter, flaked and roasted. Do these other grains bring it closer in some way?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Guinness Clone Questions

- Thread starter hawkwing

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

hawkwing

Well-Known Member

I watched one similar to that too. May have been the same guy. I picked up that they use only roasted unmalted barley in the 10% range. Not sure how close the roasted barley we can get is to their custom roasted. They also said FG 1.008. In the other video I mentioned they said they do a 90 minute boil.

I’ve been developing a recipe in both the Grainfather app and BeerSmith. I’m currently tweaking the water profile. I’m starting from distilled and using the Wicklow water profile.

I’ve been developing a recipe in both the Grainfather app and BeerSmith. I’m currently tweaking the water profile. I’m starting from distilled and using the Wicklow water profile.

Maris Otter or no? That seems to be the most fundamental difference of opinion.

hawkwing

Well-Known Member

Yes Maris Otter. I got Crisp. I'm a little concerned that I'm not seeing any yeast action though. The Package expiry I think was this month but Hopefully I'll see something by morning.Maris Otter or no? That seems to be the most fundamental difference of opinion.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

Yeast almost always pulls through. Just wait.

hawkwing

Well-Known Member

It's been 44 hours and not a sign of fermentation. I cooled the wart with my immersion cooler and I aerated for about an hour with an aquarium pump with sanitary filter and stainless diffusion stone. Not sure if I should aerate it more or not.Yeast almost always pulls through. Just wait.

I'm going away for a week too. I got another pack today. Best before on the package is the 27th same as the other one. I busted the bubble pack at the shop and if it doesn't swell up I'm taking it back and asking for a refund. I got some Safale S-04 as a backup. I might have to load the keg in my car and take it with me.

Ah, I didn't realize you were using liquid yeast. I always make a starter with liquid yeast to be sure and have a dry yeast backup plan. Good luck. Don't wait too long to get some yeast working.

Could use the second pack for a starter and then harvest the yeast to use sometime in 1-2 months?

beren

Well-Known Member

Make a 2l starter. Put half in a 2nd batch of Guiness and get some vials and make 10 starter vials Maintaining A Healthy Yeast Bank Long Term

Makes liquid yeast for each batch $1 or less

Makes liquid yeast for each batch $1 or less

hawkwing

Well-Known Member

That’s what I want to do. Years ago I harvested yeast and froze some. But then life happened and I didn’t have the time to brew for a while.

It ended up taking off just in time for me to set it up before I left. I have the gas port on my fermentation keg connected to the beverage out on the serving keg. (I cut the tube short so it doesn’t stick down). Then I put the spunding valve on the gas out on the serving keg. I set it to 10 PSI. That’s should be 1.2 volumes C02 at room temperature. Which is what a quick google said. Then I’ll just hook up with nitrogen to serve at whatever pressure it’s supposed to be. I think it needs to be higher than CO2. I might need a longer serving line not sure.

It’s also time to get my CO2 tank tested and filled. Got 1.4 lbs in a 20 lbs tank.

It ended up taking off just in time for me to set it up before I left. I have the gas port on my fermentation keg connected to the beverage out on the serving keg. (I cut the tube short so it doesn’t stick down). Then I put the spunding valve on the gas out on the serving keg. I set it to 10 PSI. That’s should be 1.2 volumes C02 at room temperature. Which is what a quick google said. Then I’ll just hook up with nitrogen to serve at whatever pressure it’s supposed to be. I think it needs to be higher than CO2. I might need a longer serving line not sure.

It’s also time to get my CO2 tank tested and filled. Got 1.4 lbs in a 20 lbs tank.

beren

Well-Known Member

Why ferment under pressure? the wyeast irish ale hits FG in like 3 days anyway

As far as freezing it's way cheaper and easier than ordering liquid in the summer... even from the lhbs.

As far as freezing it's way cheaper and easier than ordering liquid in the summer... even from the lhbs.

hawkwing

Well-Known Member

Well a few reasons. One it’s something new to try. Two it’s carbonated already. Three apparently I don’t have to worry about the temperature and flavors as much. Four I can do a closed to air transfer.Why ferment under pressure? the wyeast irish ale hits FG in like 3 days anyway

As far as freezing it's way cheaper and easier than ordering liquid in the summer... even from the lhbs.

hawkwing

Well-Known Member

I noticed that this method does not rinse the yeast. Not sure if it matters or not?Make a 2l starter. Put half in a 2nd batch of Guiness and get some vials and make 10 starter vials Maintaining A Healthy Yeast Bank Long Term

Makes liquid yeast for each batch $1 or less

beren

Well-Known Member

One you don’t harvest from beer that you made just the starter, and two I believe everybody says washing the yeast is actually worse nowadays.I noticed that this method does not rinse the yeast. Not sure if it matters or not?

hawkwing

Well-Known Member

Well it looks like my fermentation is complete. It’s been two weeks or more since I pitched. I’m not completely trusting my spunding valve. I set it to 10 psi and when I got home it was 15. I adjusted again and waited a week. Then a couple days ago it was back up higher than it’s supposed to be. Anyway today I disconnected it all and put it in the kegerator to cold crash and clean. Is a week enough for this or should I chill for 2 before transfer long time the serving keg?

Also what pressure should I set my nitrogen to and how long do I need to let it absorb before drinking? Is it similar to CO2 for time? I’ve ready 30-45 psi for nitrogen. Do I need a longer beverage line for pressure drop?

I got a stout spout for my kegerator for now. I’ll get a stout tap someday.

Also what pressure should I set my nitrogen to and how long do I need to let it absorb before drinking? Is it similar to CO2 for time? I’ve ready 30-45 psi for nitrogen. Do I need a longer beverage line for pressure drop?

I got a stout spout for my kegerator for now. I’ll get a stout tap someday.

- Joined

- Nov 26, 2013

- Messages

- 9,926

- Reaction score

- 24,098

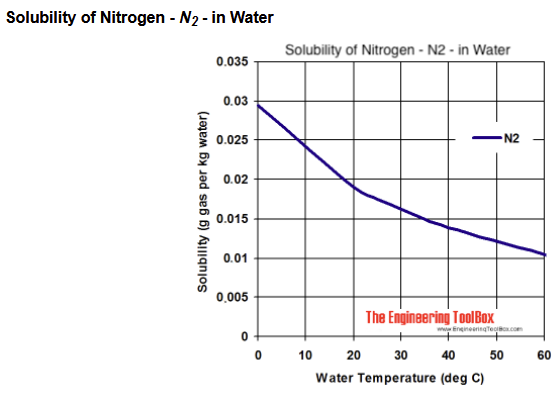

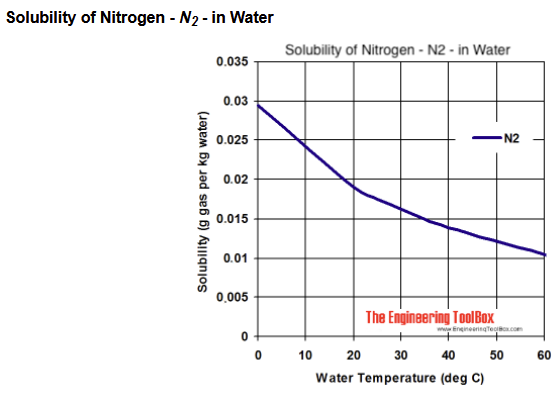

Nitrogen does not dissolve in water (beer) at least not appreciably. Typically when people serve a nitro beer they are using 75% nitrogen 25% CO2 "beer gas". Others who know more about this will have to chime in here as I have never used it. I just know Nitrogen does not dissolve like CO2 in beer.

hawkwing

Well-Known Member

Well I fermented under pressure so hopefully have close to the right amount of co2. I thought I might need a diffuser for the nitrogen but someone on here told me that was wrong thinking. I dunno. But for now I don’t have a diffuser in the keg. However the pressure for nitrogen needs to be higher.

beren

Well-Known Member

I force carb it with co2 then put it on nitro. The nitro doesn’t really dissolve in beer like co2 does that’s why it’s used for normal beer with long lines. I think I use 36 or 38 on my dial gauge. More and it has a giant head.

beren

Well-Known Member

Oh don’t try to use nitro with a normal tap. You’ll have beer shot all over at the high pressures. This says chrome but mine came stainless KegWorks Amazon.com: KegWorks European Specialty Stout Beer Faucet in Chrome: Restrictor Beer Faucet: Home & Kitchen

hawkwing

Well-Known Member

I have a stout spout for my Nukatap faucet. They say it's make for nitro beers.Oh don’t try to use nitro with a normal tap. You’ll have beer shot all over at the high pressures. This says chrome but mine came stainless KegWorks Amazon.com: KegWorks European Specialty Stout Beer Faucet in Chrome: Restrictor Beer Faucet: Home & Kitchen

hawkwing

Well-Known Member

What pressure and temperature do you force carb too? Since I pressure fermented to 10 psi at room temp or a cool room temp this time of year it should be in the ballpark for a 25% CO2 blend.I force carb it with co2 then put it on nitro. The nitro doesn’t really dissolve in beer like co2 does that’s why it’s used for normal beer with long lines. I think I use 36 or 38 on my dial gauge. More and it has a giant head.

beren

Well-Known Member

I shake it at like 25-30psi for a bit, then chill it at12psi, co2 is a lot cheaper than beergas

Also what pressure should I set my nitrogen to and how long do I need to let it absorb before drinking? Is it similar to CO2 for time? I’ve ready 30-45 psi for nitrogen. Do I need a longer beverage line for pressure drop?

I usually carbonate with 10 psi of CO2 for a few days (3 is usually enough, but I do use small kegs), then switch to 40 psi beer gas. I then wait a day for whatever nitrogen is going to dissolve. The pour is definitely different after that day wait, so getting nitrogen into solution does matter. You do not need a longer line; the stout faucet/tap provides enough restriction as it is.

hawkwing

Well-Known Member

Well it turned out great! I'm very happy with it. The Grainfather S40 worked well especially for the sale Price. Basically half regular price. I'm going to make a few mods so I can have the lid on during recirculation and not make a big mess with a decent flow rate. Pressure fermentation and carbonation with closed transfer worked well. Got it on 40 PSI nitrogen. It's not going to last.

But I was pickup up ingredients for the Wee Heavy I'm going to be making and there was a half price sale on recently past best before yeast packs of Wyeast and Imperial. Going to add them to my yeast bank. Then figure out what I'm going to make with them.

But I was pickup up ingredients for the Wee Heavy I'm going to be making and there was a half price sale on recently past best before yeast packs of Wyeast and Imperial. Going to add them to my yeast bank. Then figure out what I'm going to make with them.

Looks great!

Similar threads

- Replies

- 18

- Views

- 838

- Replies

- 48

- Views

- 2K

- Replies

- 10

- Views

- 849

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)