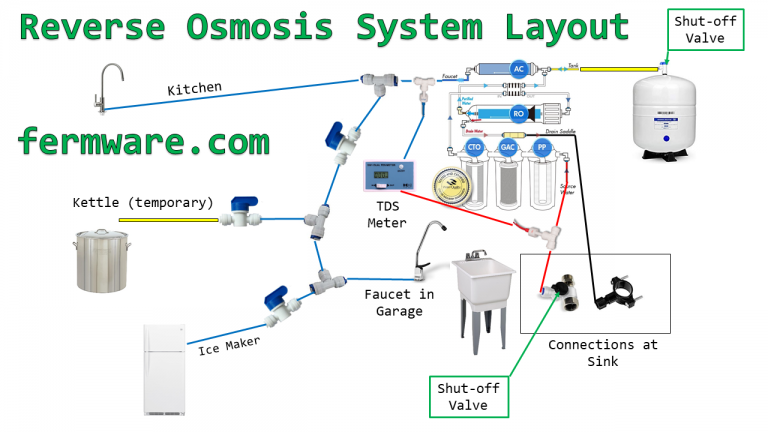

At some point in your brewing career you are going to become interested in taking your water chemistry to the next level. As part of that, you might come to the realization that you want to improve the quality of your water and stop using the water from a garden hose or you might want to cut down on the inconvenience of having to go to the store to get your water. I had waited a long time to do it, but I've had my system installed for 2 years now and I don't regret the expense one bit.

I put together a guide on reverse osmosis systems detailing

Here is a link to the full guide:

http://fermware.com/reverse-osmosis-system-installation/

I put together a guide on reverse osmosis systems detailing

- The basic components of a RO (Reverse Osmosis) system

- Some of the considerations when choosing a system

- A brief explanation of how they work

- How I chose to install my system

Here is a link to the full guide:

http://fermware.com/reverse-osmosis-system-installation/

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)