Hello Everybody. I used to post on Homebrew Digest and rec.crafts.brewing back in the 1990's. It's been a long time, but I'm back and brewing!! I have followed this thread with great interest. I used to make and use agar slants, but I just tried freezing my first batch of yeast, and I would like some feedback on a couple of points. I may be over simplifying things, so I would like to know if I've missed something.

Everybody is talking about harvesting from the primary or from a starter. But that seems to me like it is more difficult, and one generation removed from the original strain. I understand if you are not starting from a smack pack, but if you are, why not extract directly from the smack pack?

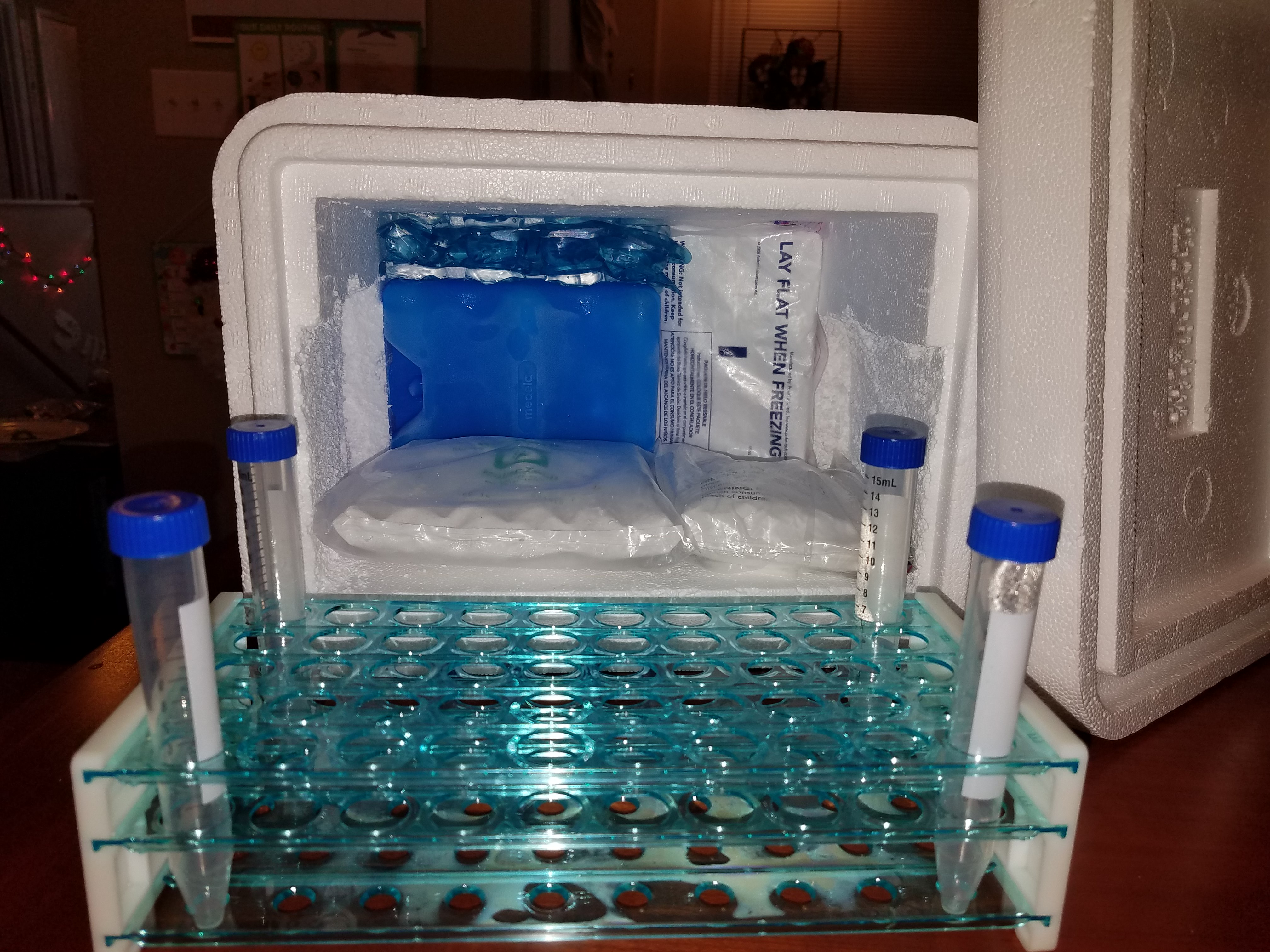

Here is the procedure I just used to freeze my first batch of yeast. If I've got something wrong, please comment!

Harvesting Yeast from Smack Pack:

(Follow basic starter, freezing, and agar slant procedures already established in previous articles.)

Prepare 6ea. sterile 15ml vials with 1.5ml glycerin in each.

Prepare 1ea. 500ml starter.

(Optional: Prepare 6 baby food jars with agar/wort media in bottom, sterilize in pressure cooker.)

From a new Smack Pack (smacked and swollen, sterilize outside of pack), extract 6ea. 10ml samples into the 15ml vials with glycerin. This will leave roughly 65ml in smack pack. Pitch this into 500ml or 1000ml starter. Take care not to contaminate smack pack. Now use inoculating loop to gather remaining yeast in bottom of smack pack to inoculate each agar slant (optional, but I wanted a back-up in case I screw up the freeze!!).

Freeze vials (per procedure)

Store agar slants (per procedure)

You now have 6ea. frozen, pitchable vials of Original Generation yeast strain, and 6ea. agar slants. When you get down to your 2nd to last vial, pitch into 200ml or 500ml starter, and begin again, as if it were a new smack pack (create 6 new frozen vials and pitch remainder into 1000ml starter). This should prevent the eventual mutation from constantly harvesting from the primary (so desu ka?, n'est pas?, RIGHT?).

Experiment in Harvesting Yeast and freezing full load from Primary:

Pitching directly into the next batch would be nice, but I'm not ready to brew yet. So... I'm freezing the the whole load. Results will follow in few months when I revive the frozen load.

(Follow basic yeast washing procedures already established in previous articles.)

For 10 gal. batch (2ea. 5 gal. carboys)

On second day of fermentation, right after blow-off had subsided, I transferred to “first secondary”, and threw out all the dredges from primary. Two days later, I transferred again to the real secondary, this time harvesting the yeast (I know... people say harvest from the primary, but this was an afterthought, and I will only be using it to pitch to another batch, not for my yeast bank.). I only put in a small amount of sterile water (~500ml) into each carboy, swirled, and poured into 1-quart, sterile mason jars (one for each carboy.) This was all viable, clean yeast, without the need for multiple washes and getting rid of the top and bottom layers. (Sorry I didn’t take pictures – thought of that afterwards!) The jars settled into 2 distinct layers (not 3 like you usually get with all the trub from the primary) – a yeast cake at the bottom, and the liquid on top. I put in refrigerator over night.

Next day:

I prepared a sterile water and glycerin solution by adding 2 oz (59-60ml). glycerine into 8oz. (~240ml) sterile water. This will render a 25% solution, which I added to the yeast slurry, which is approximately 250 – 300ml. So, depending on the density of your yeast cake, you should wind up between 12.5% to 15% glycerin in the final mix.

Decant liquid from top of yeast in mason jars (I use a sterile turkey baster to remove most of the liquid down to about 1/4” (6mm) of liquid on top of yeast, then pour off remaining liquid until yeast appears in stream. This seems to allow for removal of more liquid before yeast enters the stream.) Now pour half of sterile, 25% glycerin/water solution into each mason jar of yeast. Swirl to loosen yeast cake, and pour both jars into one sterile 1-quart mason jar. Shake vigorously to mix glycerin solution with yeast, and put in refrigerator.

Follow freezing technique to allow 48 hours to cool before final freeze.

I have a VERY old refrigerator that I keep around 50°F (10°C) for my kegs. It is just past the shutoff point of the thermostat – any further and it shuts off completely. So, the freezer never quite freezes – it stays right about 32-33°F (0-1°C). So, it is perfect for stepping down the temperature for a day or two before going into the deep freeze.

Mason jar is about 2/3 full, so plenty of room for expansion during freezing. (Even up to 3/4 full is sufficient - I freeze soup in mason jars like this all the time - so long as you have at least 1" (2.5cm) of headspace, it's fine, just keep the cap loose until it's frozen.)

Other suggestion:

I use a milk frother (Ikea - $3) to aerate my starters. Wipe the stir rod and spring with alcohol and flame to sterilize, then let it rip! Nothing but foam in less than a minute (be sure to use a large container, because volume will more than double in foam.) NOTE: Some of the Ikea frothers are stronger than others. I hot-wired mine to a 5v power adapter (they normally run 3v with 2 AA batteries.) Now it doubles as a weedeater!!

Comments welcome!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)