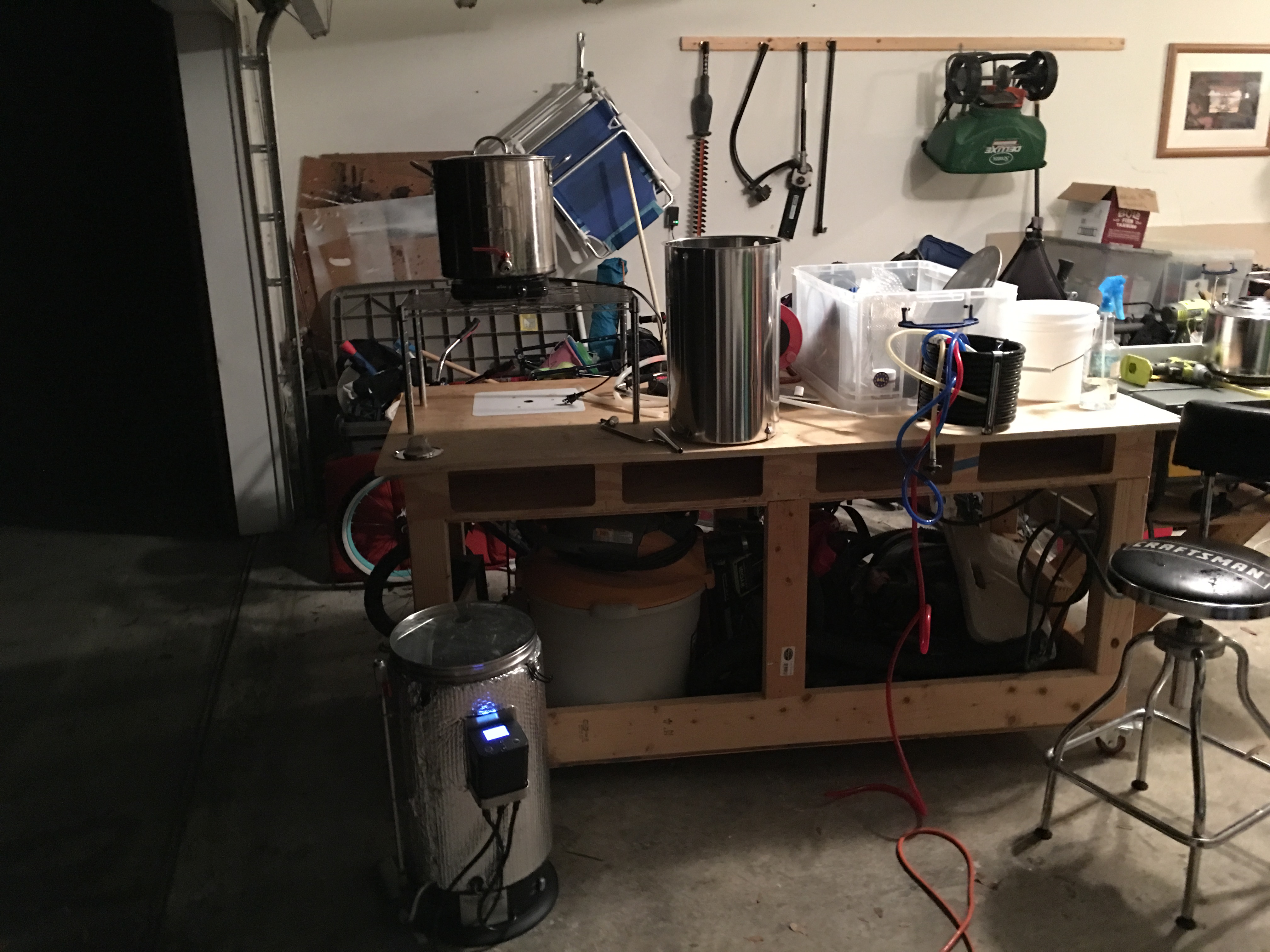

So I documented my grainfather brew day. Please give me any pointers to improve efficiency or shorten my brew day. Aside from a grainfather with a connect control box. I am using a 5 gallon pot with a cheap hot plate and inkbird thermostat. The whole process takes 6 hours total. But really only 4.5 hours if I ignore the day prior setup and the time it takes to come up to mash temp. Here is my brew day:

The night before brew day. (40 mins)

· Set up wheeled workbench with sparge pot on top of platform and burner, place thermostat near pot.

· Calculate recipe and input to Grainfather app/website.

· Rinse out Grainfather and sparge pot and fill with calculated mash and sparge volumes

o 10 lb grain bill, 5.5 gallon fermenter quantity, and 60 minute boil came out to 4.16 gallons of mash water and 3.36 gallons of sparge water.

· Place "trub trap" in Grainfather and put lid on top.

Brew Day

· As soon as you wake up/get home turn on Sparge hot plate and Grainfather, start recipe and let water come to temp. (50 mins)

· Stirred in grains, put on recirculation pipe and set to mash.

· Mashed with recirculation valve full open for 60 minutes

· After automatic mash-out at 168, sparge at 168.

· As soon as you lift the grain bin above to drain, manually turn on the heat to boil.

· Sparge occurred quickly and I tried to keep a level of water above the grain bed at all times (maybe half an inch or so). Next time I’ll try a slower sparge for better efficiency. Efficiency was calculated at 80%

· Place sparge water thermostat probe in sanitizer.

· After sparging and draining complete, take a preboil reading of gravity and volume, then put the lid back on with a towel on top to help it get to temp.

· Connect the counter-flow chiller.

· Clean everything as soon as you can, and set up sanitized materials and fermenter while the boil is taking place.

· During the last few minutes of the boil, place the silicon output hose of the counter-flow chiller in the wort and clamp in the direction of the "whirlpool" soon to come.

· After the boil with associated hop additions, kill the boil and turn on the pump. The water is still plenty hot to sanitize the counter flow chiller, while using your paddle to get a good whirlpool going.

· As soon as whirlpooling with the paddle is complete, clean it and place it in sanitizer

· Take a gravity and volume reading

· After 5 minutes of whirlpool, consider the counter-flow chiller sanitized and start the cooling water into the counter-flow chiller, give it another 10-15 minutes or whirlpooling, while cooing the wort back into the Grainfather. Collect the now heated counter-flow chiller water for cleaning later.

· After about 15-20 total minutes of whirlpool, place the temp probe from the sparge water thermostats into the counter-flow chiller output hose and place the whole thing into the fermenter. Adjust the Grainfather pump valve to reach a suitable temp. During a cold night, the valve was completely open and the output wort was 75 degrees, the Grainfather read the temp as 165 still.

· After all is transferred, use sanitized paddle to aerate wort, sprinkle yeast, close up and place in fermentation chamber.

· Rinse everything out and pour hot counter-flow chiller water back into Grainfather, mix in cleaner, turn pump and heat on (140 degrees) and let cycle for about 15 minutes. Pump out and give it all a good scrub then rinse.

· 4.5 hours from temps to full clean up.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)