just started boiling my first batch. i'm noticing a LOT of husks in the boil, at lease more than i got with my cooler mash tun with braid in it. I've scraped about a good 2 cups worth of proteins. i'm wondering if this is normal for the system or if i made a mistake. when circulating the mash i saw some husk though it seemed like very thing circulated well. I did remove the ball valve since i heard it gets clogged a lot. any ideas?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grainfather!!

- Thread starter BrewMeister49

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

just started boiling my first batch. i'm noticing a LOT of husks in the boil, at lease more than i got with my cooler mash tun with braid in it. I've scraped about a good 2 cups worth of proteins. i'm wondering if this is normal for the system or if i made a mistake. when circulating the mash i saw some husk though it seemed like very thing circulated well. I did remove the ball valve since i heard it gets clogged a lot. any ideas?

Awhile back in this thread, someone posted a sink strainer over the overflow pipe. I bought one and it keeps the husks out of the boiler. $2 fix.

@domdom This is just a simple user error. You need to adjust the re-circulation flow (via the ball valve) so not so much goes through the overflow during the mash rest.

I ignored the flow and had it wide open my first few batches and had the same problem you're having. Fiddled with the flow the 3rd batch and haven't had any issues since. I suppose you could take the route damdiver did, but IMO, that's just kinda fixing a problem that shouldn't be there in the first place.

I ignored the flow and had it wide open my first few batches and had the same problem you're having. Fiddled with the flow the 3rd batch and haven't had any issues since. I suppose you could take the route damdiver did, but IMO, that's just kinda fixing a problem that shouldn't be there in the first place.

I still think your getting most of the grain in the boil from grain getting though the bottom plate on the mash tun section. I posted sometime ago how built a triple false bottom. Works perfectly now.

I still think your getting most of the grain in the boil from grain getting though the bottom plate on the mash tun section. I posted sometime ago how built a triple false bottom. Works perfectly now.

If you get grain through the provided false bottom, then I think your grain is crushed too fine. And I would think you would get some really, really slow sparges unless you are using rice hulls. Just my opinion. I don't have an issue with grain or husks going through.

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,063

- Reaction score

- 2,256

I'm getting what seems to be a fair amount of grain or husks in the boil as well. I haven't paid that close attention to the overflow but I looked towards the end today and it was definitely flowing into the overflow even towards the end of the mash.

Could this be affecting my efficiency? Only reason I ask is I've ended up with crazy high efficiency with my first two brews. Crushing my own grain at as close to .039 as I can get and I'm getting between 91 and 95% efficiency using the calculator on the grainfather website. I measured the well stirred preboil wort with both a refractometer and a hydrometer and got the same numbers (at room temps). It takes me a while to Sparge and nothing seems to be stuck. I pour pretty slowly to try to keep that 1cm distance above the grain bed. I just take a quart at a time from a pot I warm on a camp stove in my garage. I can get it to maintain 168* pretty well. I've been mashing around 152 for 60 minutes. I thought my scale might be off but with a 30g weight it was only off by .3g so I don't think that would have that big of an effect.

Could this be affecting my efficiency? Only reason I ask is I've ended up with crazy high efficiency with my first two brews. Crushing my own grain at as close to .039 as I can get and I'm getting between 91 and 95% efficiency using the calculator on the grainfather website. I measured the well stirred preboil wort with both a refractometer and a hydrometer and got the same numbers (at room temps). It takes me a while to Sparge and nothing seems to be stuck. I pour pretty slowly to try to keep that 1cm distance above the grain bed. I just take a quart at a time from a pot I warm on a camp stove in my garage. I can get it to maintain 168* pretty well. I've been mashing around 152 for 60 minutes. I thought my scale might be off but with a 30g weight it was only off by .3g so I don't think that would have that big of an effect.

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

Diamonddave74

Active Member

- Joined

- Mar 27, 2016

- Messages

- 38

- Reaction score

- 10

I doubt many grains are getting through the bottom or top plate. If so then the crush is too fine but doubt that's it.

Have a picture on the amount of grain? I get some but not a lot at all.

Have a picture on the amount of grain? I get some but not a lot at all.

crusader1612

Well-Known Member

Awhile back in this thread, someone posted a sink strainer over the overflow pipe. I bought one and it keeps the husks out of the boiler. $2 fix.

Or get the new filter, and coverthe overflow with the old filter.

I doubt many grains are getting through the bottom or top plate. If so then the crush is too fine but doubt that's it.

Have a picture on the amount of grain? I get some but not a lot at all.

I'm crushing grain with a Monster Mill Pro3 mill, but have tried the Barley Crusher also. The bottom plate is the main issue for grain in boiler. The stirring action on mash in pushes the grain though the plate. I'm sure it varies from crush to crush or how much the person moves his/her spoon around the bottom. My triple bottom makes it harder for the grain to work its way past.

Brewmasher

Well-Known Member

- Joined

- Jun 10, 2016

- Messages

- 163

- Reaction score

- 61

Try conditioning your grain next time. After weighing, mist it with 3-4 oz water or star san and give it a good toss. It helps if you seal it up in a container for a few hours or overnight before crushing, but it's not necessary. This keeps the husk from splintering into tiny fragments allowing a finer crush, better circulation and lautering.

dibbz

Active Member

- Joined

- Aug 26, 2014

- Messages

- 40

- Reaction score

- 7

Just FYI, brewing today so I ran my mash through a strainer for 10 minutes when bringing it to a boil and pulled out this, it is all very small and probably not a problem, but I might keep doing it.

http://imgur.com/1ZN4v5B

http://imgur.com/1ZN4v5B

one thing that might have been the reason for all the grain in my boil was that i tried doing a low mash at 113F for 10 minutes. I gathered hot water from my tap for this and has a starting temp of about 120. the temp didn't drop as much as I thought it would after adding grain so I added a couple ice cubes and plunged the mash grain container in and out a few times to bring the temp down. Next time i'm going to do a simple single temp infusion and see if i end up with less grain in the boil. if now, i'll add some stainless steel mesh to the bottom.

Did my first brew with the GF last night. A weeknight is definitely not the best to use a new system for the first time. I started at 5:30 and finished at 11:00. It will take some time getting used to; the chilling and cleaning more than anything else. I was <4hrs with my cooler/kettle set up so that's going to be a high bar to beat. The all in one convenience was very nice and I was able to sparge right from my stovetop by just controlling the kettle valve (no more lifting 5+ gallons repeatedly!). Sparge went very quickly with a small grain bill, about 20 minutes total.

Recipe only used 2oz of hops but they formed a nice barrier/filter on the pump intake and the wort was very clear out of the chiller. Boil came within 20 minutes with Graincoat on there and was plenty strong.

I ended up letting the wort sit overnight and pitched this morning. Tap water here is 85 degrees and I didn't have the pieces to set up my old immersion chiller as a pre-chiller. Definitely will by next batch though as chilling in the summer is a nightmare. I can see this counterflow chiller will be awesome in the winter.

Recipe only used 2oz of hops but they formed a nice barrier/filter on the pump intake and the wort was very clear out of the chiller. Boil came within 20 minutes with Graincoat on there and was plenty strong.

I ended up letting the wort sit overnight and pitched this morning. Tap water here is 85 degrees and I didn't have the pieces to set up my old immersion chiller as a pre-chiller. Definitely will by next batch though as chilling in the summer is a nightmare. I can see this counterflow chiller will be awesome in the winter.

StoutNoDoubt

Well-Known Member

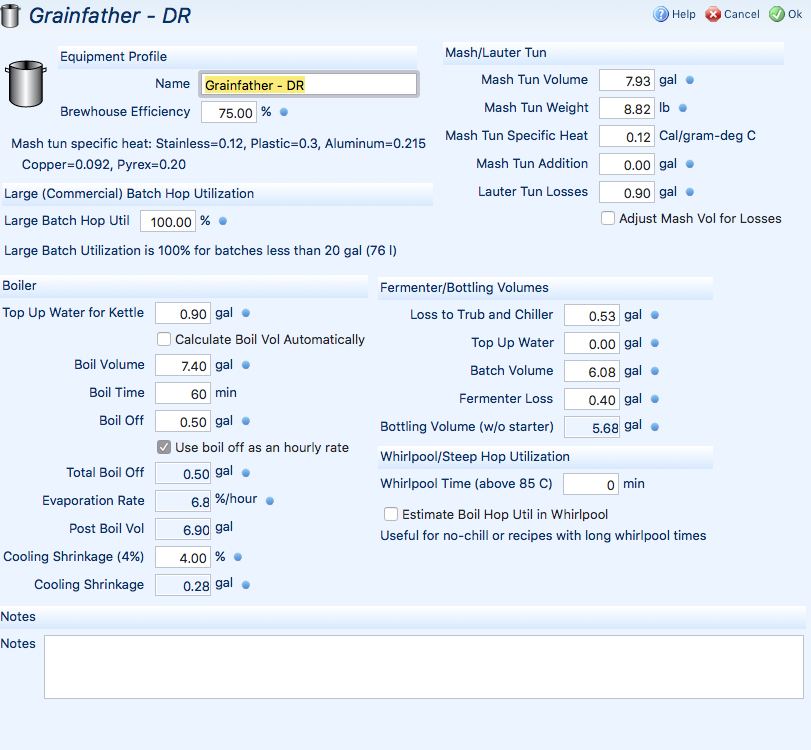

I posted three files on March 24 -- p. 124 of this thread -- https://www.homebrewtalk.com/showthread.php?t=550870&page=124 -- that should help. Read the entire pdf-file and make all three sets of changes, and you should get fairly closel

I noticed on this beersmith profile that you have your final batch volume set to 6 gallons versus the typical 5. Is there a reason or do you bottle 6 gallons when you brew, typically?

I noticed on this beersmith profile that you have your final batch volume set to 6 gallons versus the typical 5. Is there a reason or do you bottle 6 gallons when you brew, typically?

I've used these profiles for my brews and thought the same thing. I was going to adjust it, but figured not to screw with it.

In the end, I just figured, "Who cares". The extra left in the GF after I fill my fermenter (which also has extra volume in it) is not costing that much more and I'm assured of having my cornies filled to the 5 gallon mark every time. Plus, on the heavy dry hop batches the extra liquid that gets absorbed doesn't leave me with a "short batch".

FYI, the one change I've made to the profile was dialing in my efficiency at 85%. That's what I get with my Barley Crusher .038" mill setting. Slower sparge, but rice hulls helped and I have yet to overlap the sparge with the boil (boil switch on when sparge starts). Gotta wait for the boil to come up so who cares about the length of the sparge.

Brewing_CSU_Ram_Fan

Member

- Joined

- Feb 18, 2016

- Messages

- 20

- Reaction score

- 8

Latest brew results...

Early in my brewing on the grainfather I was having horrible efficiency. I brewed 8 or 9 batches within the first two months of having the grainfather, I still could not get it right and efficiency was just at 60% or slightly higher. (this discussion is earlier in this thread and mostly concerns sparging).

After taking a break because of work travel, I have started brewing again. I have brewed 6 batches in the last 4 weeks and I am now getting 80% or better now because of one simple factor... double milling. I have started double milling the grain at my LHBS and adding rice hulls as a standard addition to my recipe. I have noticed that as a result of the double milling, the mash flow is much slower and the flow rate has to be adjusted down or the wort will go through the overflow tube. Lastly, because of the thicker mash from double milling, the sparge process is taking much longer but I feel that it is much more efficient.

Just thought I would share this as others might have had the same problem.

Early in my brewing on the grainfather I was having horrible efficiency. I brewed 8 or 9 batches within the first two months of having the grainfather, I still could not get it right and efficiency was just at 60% or slightly higher. (this discussion is earlier in this thread and mostly concerns sparging).

After taking a break because of work travel, I have started brewing again. I have brewed 6 batches in the last 4 weeks and I am now getting 80% or better now because of one simple factor... double milling. I have started double milling the grain at my LHBS and adding rice hulls as a standard addition to my recipe. I have noticed that as a result of the double milling, the mash flow is much slower and the flow rate has to be adjusted down or the wort will go through the overflow tube. Lastly, because of the thicker mash from double milling, the sparge process is taking much longer but I feel that it is much more efficient.

Just thought I would share this as others might have had the same problem.

I posted three files on March 24 -- p. 124 of this thread -- https://www.homebrewtalk.com/showthread.php?t=550870&page=124 -- that should help. Read the entire pdf-file and make all three sets of changes, and you should get fairly closel

I just made the adjustments that were in the PDF and I have a few questions.

1) After the "Check boil off as an hourly rate" it says the evaporation rate should be 7.2%/hour but on my beersmith, it says 6.8%/hour. I swear everything prior to this step is perfect. Will this make much of a difference?

2) I noticed that the hourly boil-off rate is 0.5 gal per hour. However, after a few batches, I've noticed that I'm getting about 0.5gal per 30 mins. I have the double-layered reflectix layer on my GF. How should I go about making adjustments for this?

Sorry if these are noob questions...I'm fairly new to beersmith and obviously my GF

treacheroustexan

Well-Known Member

So I have a couple cleaning questions. After brew day, I have always just ran hot water through the chiller, no PBW or anything. Is this okay, or before my next brew day should I run a pbw/oxy solution through it? I have had a few infection scares my past two brews that I brewed on the grainfather. I'm wondering if my cleaning procedure has something to do with it? I recirculate the boiling wort through for 10 minutes so I wouldn't think that it would, but who knows. Brewing this weekend so interested to hear your guys thoughts.

lewandowski46

Well-Known Member

After each brew you should run PBW through so it doesn't collect solids on the inside of the CFC, those solids could become a house for bacteria and make it harder to sanitize. PBW/Oxy is a cleaner though, not a sanitizer. The CFC get's sanitized upon pumping the boiling wort through it. With that said, if there's a buildup of solids it makes it that much harder to sanitize if there's places for bacteria to hide.

I would also say cleaning it right away after brewing will make it easier to clean. If you wait, those solids harden and become more difficult to get clean.

I would also say cleaning it right away after brewing will make it easier to clean. If you wait, those solids harden and become more difficult to get clean.

scallopking

Well-Known Member

- Joined

- Sep 23, 2015

- Messages

- 198

- Reaction score

- 46

I run a 1-2 gallon of One Step through it completely, then use the Star San leftover from the sanitizing the yeast packet, scissors and paddle and run 1-2 gallons of that through it finally, let it drain out and store away.

MeanLowerLow

Well-Known Member

- Joined

- Feb 18, 2016

- Messages

- 84

- Reaction score

- 22

So I have a couple cleaning questions. After brew day, I have always just ran hot water through the chiller, no PBW or anything. Is this okay, or before my next brew day should I run a pbw/oxy solution through it? I have had a few infection scares my past two brews that I brewed on the grainfather. I'm wondering if my cleaning procedure has something to do with it? I recirculate the boiling wort through for 10 minutes so I wouldn't think that it would, but who knows. Brewing this weekend so interested to hear your guys thoughts.

Here's something I've learned:

I was using the CFC hose to fill my GF and Sparge Heater as it provided a nice hose for me to fill everything. I then started getting a really nasty plastic/vinyl flavor in all of my beers, after 12-15 successful brews with the GF, using campden in all just to be safe.

So last week I go to brew again (I took a break from brewing because I'm basically going to have to dump 4-5 more kegs, and I've already dumped 3, which is both painful and disheartening), and I use bottled water because I know our local water is hard and gets worse in the summer. At the end, when I hook up my CFC to get ready to cool, the water being discharged from the fresh side of the CFC smells HORRIBLY of plastic/vinyl. It was at this moment that I realized the problem was my water supply, per se, it was that sediment had collected over the 15 good brews in the CFC. I always pump pbw through the part of the CFC that the wort flows through, but that didn't help the fresh water part that never gets cleaned.

I supposed I could hook up a pump to clean the fresh water part of the CFC, but in reality I just will not use the CFC as a fresh water supply hose going forward. I don't think your issues are related to mine, but I wanted to throw my experience out there.

Another thing, I always dump the first pint or so of wort down the drain before I start running the boiling worth through the CFC to sterilize. In my mind, this gets any residual water that may be left from the last brew into the sink instead of my wort. This is hopefully just being overly cautious.

Last edited:

Here's something I've learned:

I was using the CFC hose to fill my GF and Sparge Heater as it provided a nice hose for me to fill everything. I then started getting a really nasty plastic/vinyl flavor in all of my beers, deposit 12-15 successful brews with the GF, using campden on all just to be safe.

So last week I go to brew again (I took a break from brewing because I'm basically going to have to dump 4-5 more kegs, and I've already dumped 3, which is both painful and disheartening), and I use bottled water because I know our local water is hard and gets worse in the summer. At the end, when I hook up my CFC to get ready to cool, the water being discharged from the fresh side of the CFC smells HORRIBLY of plastic/vinyl. It was at this moment that I realized the problem was my water supply, per se, it was that sediment had collected over the 15 good brews in the CFC. I always pump pbw through the fpart of the CFC that the wort flows through, but that didn't help the fresh water part that never gets cleaned.

I supposed I could hook up a pump to clean the fresh water part of the CFC, but in reality I just will not use the CFC as a fresh water supply hose going forward. I don't think your issues are related to mine, but I wanted to throw my experience out there.

Another thing, I always dump the first pint or so of wort down the drain before I start running the boiling worth through the CFC to sterilize. In my mind, this gets any residual water that may be left from the last brew into the sink instead of my wort. This is hopefully just being overly cautious.

I noticed the very bad plastic/vinyl smell from the CFC from day one after unboxing and sanitizing (could smell it coming from the wort out hose, too). I have two brews done so far and neither of them have an off flavor. One in the keg and one in the fermenter. I was worried about it ruining my beers but neither of them are showing signs of it. Good to know on filling the GF with water from the CFC. I have been using RO water and love it.

I have been cleaning everything with 1-2 gals of PBW, 1-2 of clean water. I use a sponge to clean the walls of the kettle while things are re-circulating. I see no reason to fill it all the way up and use the extra PBW.

Brewmasher

Well-Known Member

- Joined

- Jun 10, 2016

- Messages

- 163

- Reaction score

- 61

I'm basically going to have to dump 4-5 more kegs, and I've already dumped 3, which is both painful and disheartening),

Man, can't you donate this to the homeless? A local fraternity should be able to drain those in a couple of days. Maybe you can work out a "work for beer" arrangement with the locals. I know how much work goes into brewing, and I know what your dumping is way better than the cheap crap most of these folks drink. There just has to be a better way.

MeanLowerLow

Well-Known Member

- Joined

- Feb 18, 2016

- Messages

- 84

- Reaction score

- 22

I noticed the very bad plastic/vinyl smell from the CFC from day one after unboxing and sanitizing (could smell it coming from the wort out hose, too). I have two brews done so far and neither of them have an off flavor. One in the keg and one in the fermenter. I was worried about it ruining my beers but neither of them are showing signs of it. Good to know on filling the GF with water from the CFC. I have been using RO water and love it.

I have been cleaning everything with 1-2 gals of PBW, 1-2 of clean water. I use a sponge to clean the walls of the kettle while things are re-circulating. I see no reason to fill it all the way up and use the extra PBW.

I'm going to use RO for the first time tomorrow - and I'm going to add some Calcium Chloride as I'm brewing a German Hefe.

I clean with 4 gal of PBW, then 4 gal of clean water. I run both through the CFC and mash arm for 10 min each - this basically gives me enough time to get everything else cleaned while these cycles are running.

dmenace79

Member

- Joined

- Apr 7, 2016

- Messages

- 22

- Reaction score

- 3

I just made the adjustments that were in the PDF and I have a few questions.

1) After the "Check boil off as an hourly rate" it says the evaporation rate should be 7.2%/hour but on my beersmith, it says 6.8%/hour. I swear everything prior to this step is perfect. Will this make much of a difference?

2) I noticed that the hourly boil-off rate is 0.5 gal per hour. However, after a few batches, I've noticed that I'm getting about 0.5gal per 30 mins. I have the double-layered reflectix layer on my GF. How should I go about making adjustments for this?

Sorry if these are noob questions...I'm fairly new to beersmith and obviously my GF

I just made a profile and mine reads the same. 6.8 Percent. Did anyone ever figure out the discrepancy? Or does it matter?

dmenace79

Member

- Joined

- Apr 7, 2016

- Messages

- 22

- Reaction score

- 3

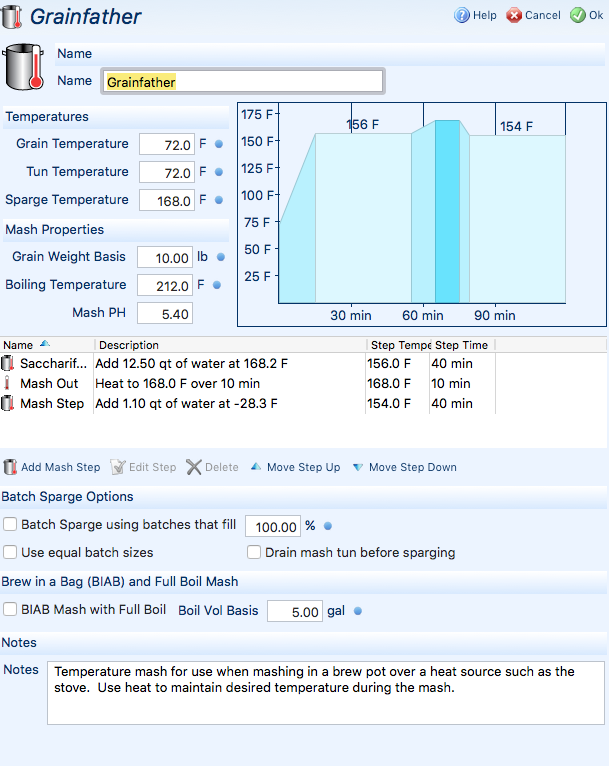

If you use BrewSmith to develop your recipes, it will assist in establishing the right strike water temperature by entering the grain temperature in the mash profile. I've found it does a rather good job providing you have changed some settings in BeerSmith to fit the Grainfather. Use the attached profiles and explanation to make the necessary changes. By the way, by making these changes, BrewSmith's inability to accurated calculate mash and sparge water quantities are also fixed

This is a screen shot of my Beer Smith, that shows the 6.8% that CPHAM was talking about. I was also confused about which temp mash profile in step three to use? I just picked a random one and entered the numbers you had on the PDF. Will my profile just add those mash numbers by default when entering a recipe?

Thanks

MeanLowerLow

Well-Known Member

- Joined

- Feb 18, 2016

- Messages

- 84

- Reaction score

- 22

Man, can't you donate this to the homeless? A local fraternity should be able to drain those in a couple of days. Maybe you can work out a "work for beer" arrangement with the locals. I know how much work goes into brewing, and I know what your dumping is way better than the cheap crap most of these folks drink. There just has to be a better way.ipe:

I tell you man, the ones I poured out already were flat out the most disgusting beer I've ever tasted. They made Milwaulkee's Best taste like Dom Perignon.

For the other 5 in question, I'm going to run a taste test with my family on Saturday... And rank them as either dump, keep to give away/throw a party, and good to drink. I think I will be lucky if two are worth saving. I guess that's what happens when you have a problem in your process pop up when you're brewing twice a week (I was brewing for my friends wedding when the issue first popped up, luckily I had some I had brewed for myself to replace what I brewed for the wedding so I wasn't totally up **** creek)

Brewing_CSU_Ram_Fan

Member

- Joined

- Feb 18, 2016

- Messages

- 20

- Reaction score

- 8

I noticed the very bad plastic/vinyl smell from the CFC from day one after unboxing and sanitizing (could smell it coming from the wort out hose, too). I have two brews done so far and neither of them have an off flavor. One in the keg and one in the fermenter. I was worried about it ruining my beers but neither of them are showing signs of it. Good to know on filling the GF with water from the CFC. I have been using RO water and love it.

I have been cleaning everything with 1-2 gals of PBW, 1-2 of clean water. I use a sponge to clean the walls of the kettle while things are re-circulating. I see no reason to fill it all the way up and use the extra PBW.

I have a buddy who has a still. I have had 2 bad batches in the years of brewing... we ran them through the still. Might give you the excuse to purchase the alembic dome distilling kit for GF.

I run a fresh rinse of water through the wort line just before brewing... drain it... and then I also pour out the first pint when sanitizing the wort line. It seems like a lot, but it is less than 30 seconds to give it that fresh water run and drain before hooking up to the GF.

I haven't used the water line to fill the GF as I learned my lesson back in the day using a water hose to fill up my HLT when I gravity brewed. I now only pour water into a container straight from the house spigot.

lewandowski46

Well-Known Member

I use one of these with the matching 10 ft hose you can get with it as well. Important the type of hose as its made for drinking water and does not impart that runner/plastic smell. I fill up a couple 5 gal buckets with water through the filter and add my brew salts. Have made excellent beer with it.

A key when using a carbon filter is to let the water flow slowly, give the carbon time to absorb the chlorine. I shoot for 1/2 gal a min flow rate through the filter.

Camco 40043 TastePURE Water Filter with Flexible Hose Protector https://www.amazon.com/dp/B0006IX87S/?tag=skimlinks_replacement-20

A key when using a carbon filter is to let the water flow slowly, give the carbon time to absorb the chlorine. I shoot for 1/2 gal a min flow rate through the filter.

Camco 40043 TastePURE Water Filter with Flexible Hose Protector https://www.amazon.com/dp/B0006IX87S/?tag=skimlinks_replacement-20

Last edited by a moderator:

Similar threads

- Replies

- 15

- Views

- 1K

- Replies

- 24

- Views

- 2K