Diamonddave74

Active Member

- Joined

- Mar 27, 2016

- Messages

- 38

- Reaction score

- 10

Is the GF UL approved ?

I believe they used ETL. Same thing really. Just different certification entities.

Is the GF UL approved ?

Yes, I just saw that. They announced it on their Facebook page as well. Here's a link to the bundle deal they're offering.

https://www.grainfather.com/shop/grainfather/grainfather-connect-bundle.html

The bundle deal is the same price as when the new ones come out. They are just trying to liquidate all of the old grainfathers with the "normal/mash" switches because going forward they will all have just an on/off switch instead. Doesn't bother me any just leaving it on normal, so why not get an extra controller in case something goes wrong?

Link is broken.

Where did you get the figures for your mash and sparge volumes? For a 5.25 gal. batch, the Grainfather calculator calls for 4.81 gal. mash water and 2.65 gal. sparge water for a 60 min. boil, or 2.91 gal. for a 90 min. boil.

https://www.grainfather.com/brewing-calculators

Why do you have lauter/mash tun losses? Those should be 0 or counted as a mashtun addition.

Why do you have too-up water for the kettle? Are you losing an equivalent volume somewhere?

Hey all, I just got an email that the Grainfather Connect is (finally) available in the US! I have already ordered mine. Really looking forward to trying it out - I will post some thoughts after I get to use it in case anyone is interested. I'm hoping it will allow me to brew during a workday by setting up before work, then having the water heated by the time I get home.

Is it not possible to change that "tap valve" on the GF heater to a ball valve? I am asking because that is what I was planning on doing to mine. Was hoping it had been done before.

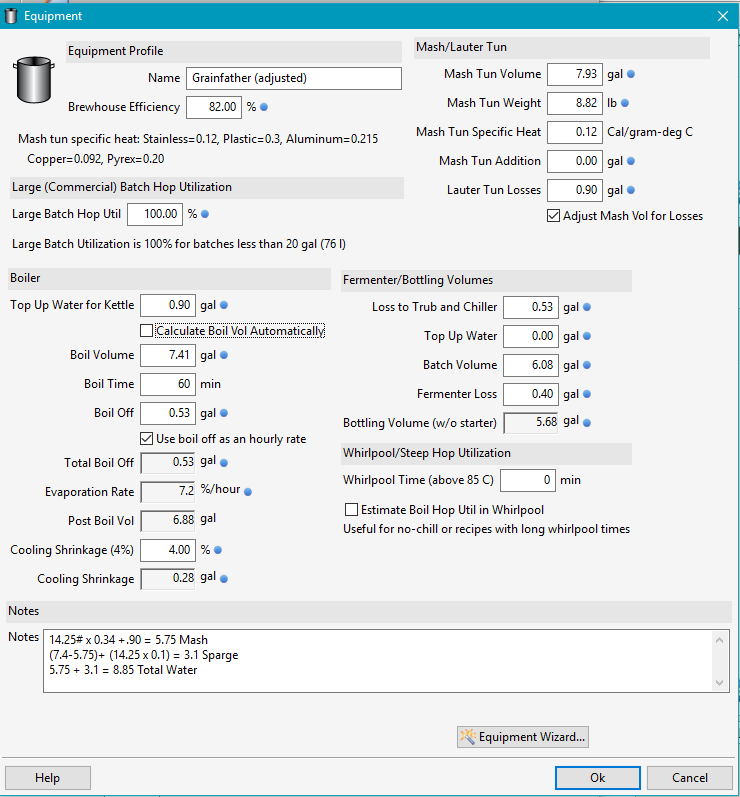

damn good question. I have no idea. I followed the profile adjustments from this thread. I changed those, and I got 4.1 gallons for mash, and 4.4 gallons sparge. After absorption, this seems a bit more accurate.

Another resource is to check would be if beersmith has a grainfather equipment profile.

Its possible, but you would most likely ha r to drill out the opening g, voiding any warranty

Mine is over soon so I will be doing this.

How does one empty a GF after cleaning it ?

Does some water remained trapped in the tube going to the pump ?

Concerning the new controller, I read the description of it AFTER I bought it [emoji3] as that was never a question. Anyway, the description says 2000w heating. I'm wondering if this new controller is able to turn on both heating elements, if indeed there are two, for an increased boil as opposed to the 1600w OR 400w we've all been brewing with.

Here is my equipment profile with calcs in the notes area based on the original GF instruction manual formula.

Also, I made these adjustments:

http://www.beersmith.com/forum/index.php/topic,14483.msg57259.html#msg57259

I hit my efficiency, vols and gravities spot on most of the times.

I ordered the new controller from AIH today as well to see how it works out.

I decided to order this ball valve for the sparge heater for now to run inline. Hopefully it will flow enough. They do have a 1/2" version as well but I got the 3/8".

https://www.kegworks.com/inline-ball-valve-shut-off

I also ordered the blichmann brumometer 3/8" to run inline on the wort out side of my chiller so I can tell the actual temp of the wort coming out.

I think these few things should dramatically help with the ease of use of the grainfather, especially once the grainfather recipe builder gets released.

That's exactly what I proposed...let me know how it works out ASAP as our GF controllers aren't in til February on this side of the line...I'm likely not brewing until then...just fermenting Festa all grains...

Will do.

For anyone who wants to add a brumometer to their chiller, there is one in the for sale section of this forum right now for $16 shipped. I wish I would've seen that before I bought mine.

Also, what are you guys running your grain mill gap setting at? I saw somewhere but can't find it now, that .55 was recommended for the grainfather.

Also, what are you guys running your grain mill gap setting at? I saw somewhere but can't find it now, that .55 was recommended for the grainfather.

brewed quite a bit with my grainfather, just a couple things

1. That stupid check valve is a pain in the dick, i have taken it out and its not going back in.

2. Longer hose on the inlet of the chiller, this would make cleaning easier so it doesnt have to sit on top.

3. Im certain the grainbed isnt staying at the proper temperature when mashing, now this is a complicated problem because grainbed drainage is different with each brew. Im brewing this weekend and i want to stick my remote thermometer in the middle of my grainbed and monitor the temperature.

This unit is still so great for apartment brewers!

Yes on the apartment. Whether or not my grain bed temperature is accurate, I haven't made a brew with mine that has disappointed me.