I agree with

@grampamark, adjusting it is a little frustrating, but once you have both sides evened out and tightened up, it's fine.

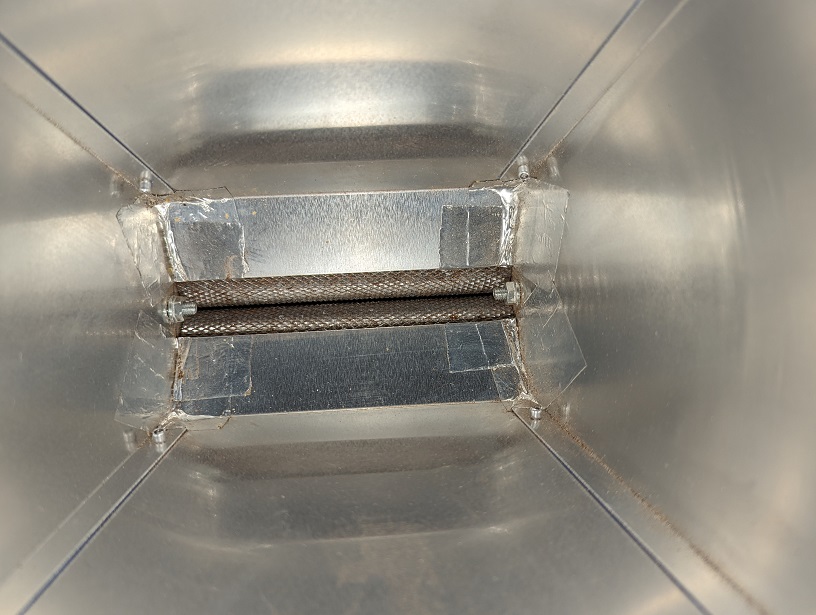

Another slight negative is the gaps on the hopper leading down to the rollers, which may also exist in other mills. For this I used some aluminum tape, allowing just a little flex so when grains are loaded in, the tape isn't entirely supporting the weight. It may not be needed as once grains are loaded in, the gap may be too small for a grain to slide through, but I have OCD.

View attachment 755074

View attachment 755073

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)