volatileant

Member

- Joined

- Apr 28, 2021

- Messages

- 5

- Reaction score

- 1

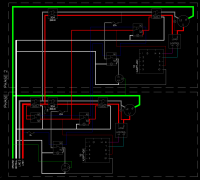

I'm looking for a bit of a sanity check, as I have been going around in circles simultaneously trying to cobble together an eBIAB system on the cheap for now (scored a new BruGear 15 gallon kettle with TC ports and fittings for $45!), while planning out the controller to eventually power the mash/boil kettle while simultaneously heating/holding sparge water in another kettle. This future mash/boil kettle would have a grain basket a-la Spike Solo/Grainfather/etc to facilitate sparge. Further down the road, I would like this controller to power a still in manual mode on the PIDs to fuel a motorcycle converted for ethanol.

Iteration 1 would be built to power a single 5500w element, essentially Doug's design from here in an oversized enclosure, swapping the 30a main power contactor with 50a part and 6ga input.

Iteration 2 would basically double everything up to separately control two 5500w elements.

Even Iteration 1 is probably overkill for the 15 gallon kettle, but would rather spend a bit more up front rather than start from scratch in a year or two.

Any flaws in that plan? Is it even worth doing? What better options am I missing?

Iteration 1 would be built to power a single 5500w element, essentially Doug's design from here in an oversized enclosure, swapping the 30a main power contactor with 50a part and 6ga input.

Iteration 2 would basically double everything up to separately control two 5500w elements.

Even Iteration 1 is probably overkill for the 15 gallon kettle, but would rather spend a bit more up front rather than start from scratch in a year or two.

Any flaws in that plan? Is it even worth doing? What better options am I missing?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)