I'm in the parts & materials gathering stage of my electric HLT build to which I will incorporate a HERMS system later. I plan on installing a 4500 element into an aluminium kettle I've used for my 5 gal. gas fired brews in the past. I'm ready to proceed with installing a dedicated 220v GFCI circuit [via a spa panel from home depot] to service the new setup [an endeavor I'm familiar and comfortable with]. My desire to stay alive and ensure the electrical safety of those near me, brings me to a few fundamental questions when wiring up the PID, SSR and the element for 220v:

1. There are 2 terminals on the element. The schematics I see around the web point to one leg of the 220 supply being run directly from the service to one of the terminals; and the other ran through the SSR [ending at the other terminal]. Is this correct?

2. I see some setups using "contactors" between the SSR and the Element? What is the purpose of a contactor and how is it used correctly in a basic setup?

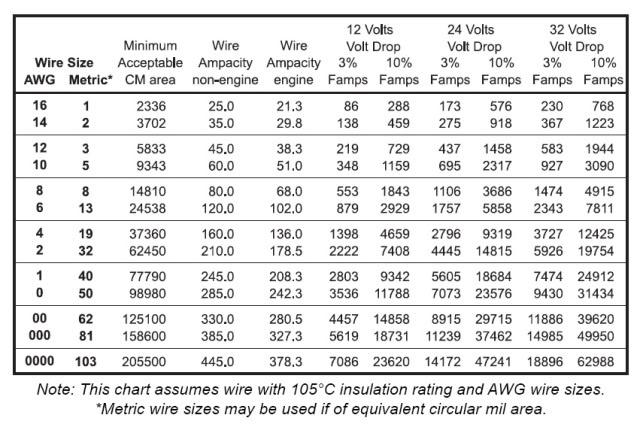

3. I have a 50 amp dedicated circuit feeding the 50amp GFCI spa panel. Is it safe to use 30 amp rated wire/connectors from this point out to the element? A run likely to be as far as 40-50 feet.

Lastly, this is my first go at seeking the guidance of my fellow homebrewers. I have learned nearly all I have from this very site. Thank you to those that have contributed their advice and those that have asked such specific questions; many of which I have had myself and had answered so well right here. I appreciate the consideration of anyone that can help guide me on this project.

1. There are 2 terminals on the element. The schematics I see around the web point to one leg of the 220 supply being run directly from the service to one of the terminals; and the other ran through the SSR [ending at the other terminal]. Is this correct?

2. I see some setups using "contactors" between the SSR and the Element? What is the purpose of a contactor and how is it used correctly in a basic setup?

3. I have a 50 amp dedicated circuit feeding the 50amp GFCI spa panel. Is it safe to use 30 amp rated wire/connectors from this point out to the element? A run likely to be as far as 40-50 feet.

Lastly, this is my first go at seeking the guidance of my fellow homebrewers. I have learned nearly all I have from this very site. Thank you to those that have contributed their advice and those that have asked such specific questions; many of which I have had myself and had answered so well right here. I appreciate the consideration of anyone that can help guide me on this project.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)