Finally found the pics of this conversion. Basically, if anyone wants to convert this to a tower, but locate it towards the back, this is the way to go.

If you open the door and lift up the plastic top with minimal effort, it comes right off. You can see what the top looks like in this blurred image. just cheap plastic, and barely glued down.

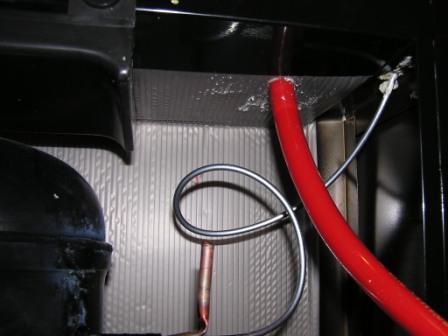

In this image you can see what you have to remove next. It is foam insulation that seems like the expandable foam type so that it is pretty well stuck to the plastic liner of the fridge. In between the foam and the inside plastic contains the coolant lines. They are wrapped around the outside of the plastic fridge liner, and secured to it with what I remember to be metal-tape. You can see them in the next pic:

I basically used a filet knife and a spatchula to pull out the foam where I put the tower. The foam is a good two and a half inches deep, but be very careful not to push to hard or too deep with the knife, cause if you knick a coolant line your screwed.

After you get all the foam out of the way, pick a spot between the coolant lines, and drill with a holesaw. Then line up the plastic top, mark and drill the top out as well. After this step, its pretty much up to you how to proceed.

I elected to put a false top over the plastic. First I secured the plastic top back on with some heavy duty silicone. Then 5/8 plywood with the silicone. I finished up with some cultured slate tiles, oak and pine trim wrap. Custom fabbed tower screwed down to the plywood. Just have to install the second faucet next week.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)