AussieDamo

Active Member

Gents,

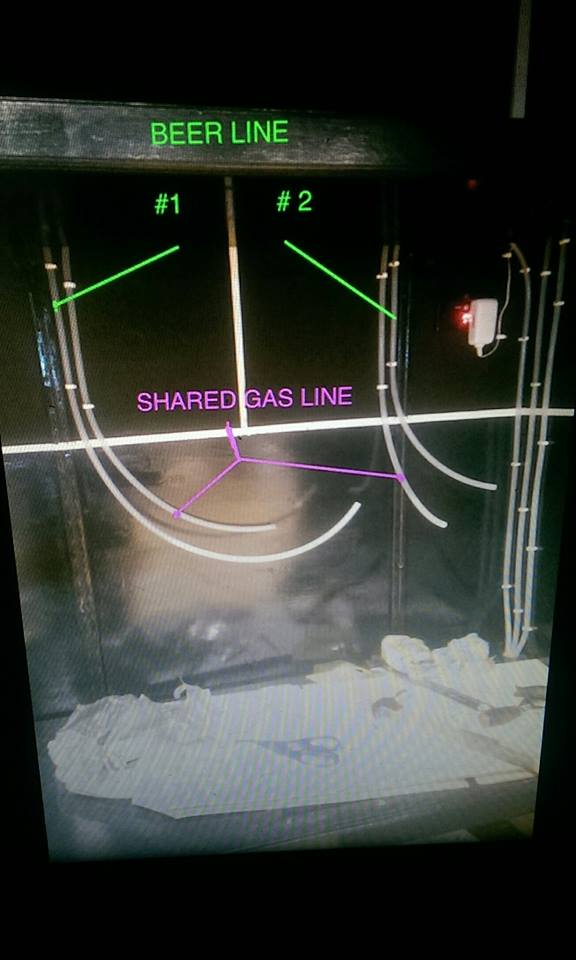

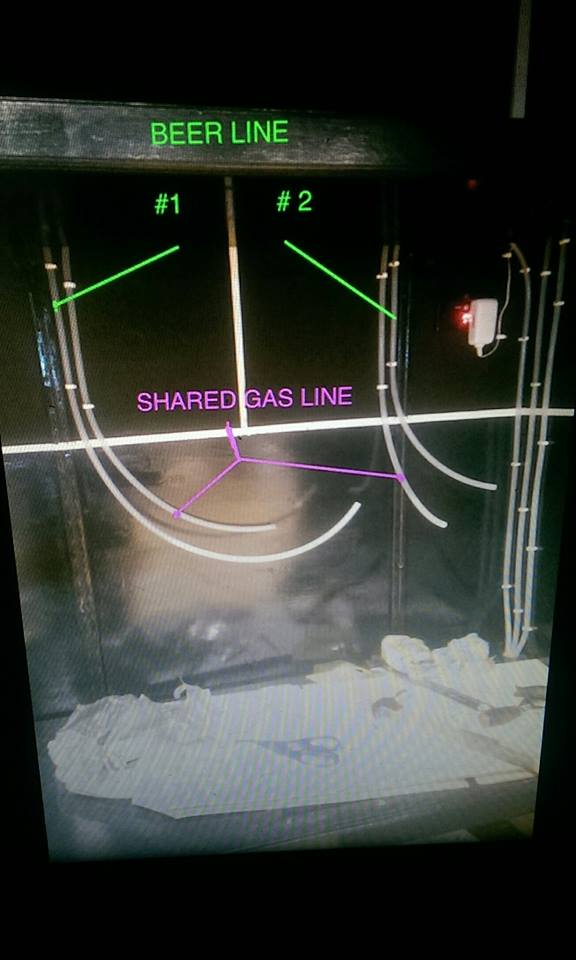

I've installed a new beer system at work with two counter pressure filling guns to dispense the beer. Pics are attached. Everything is good to go but I have been testing it and all I am getting through either gun is pure foam.

The beer kegs and gas cylinder are situated in a cool room kept at the same constant temperature. Each line is probably only about 3-4 metres long in total so I don't think temperature change over distance should be too much of an issue?

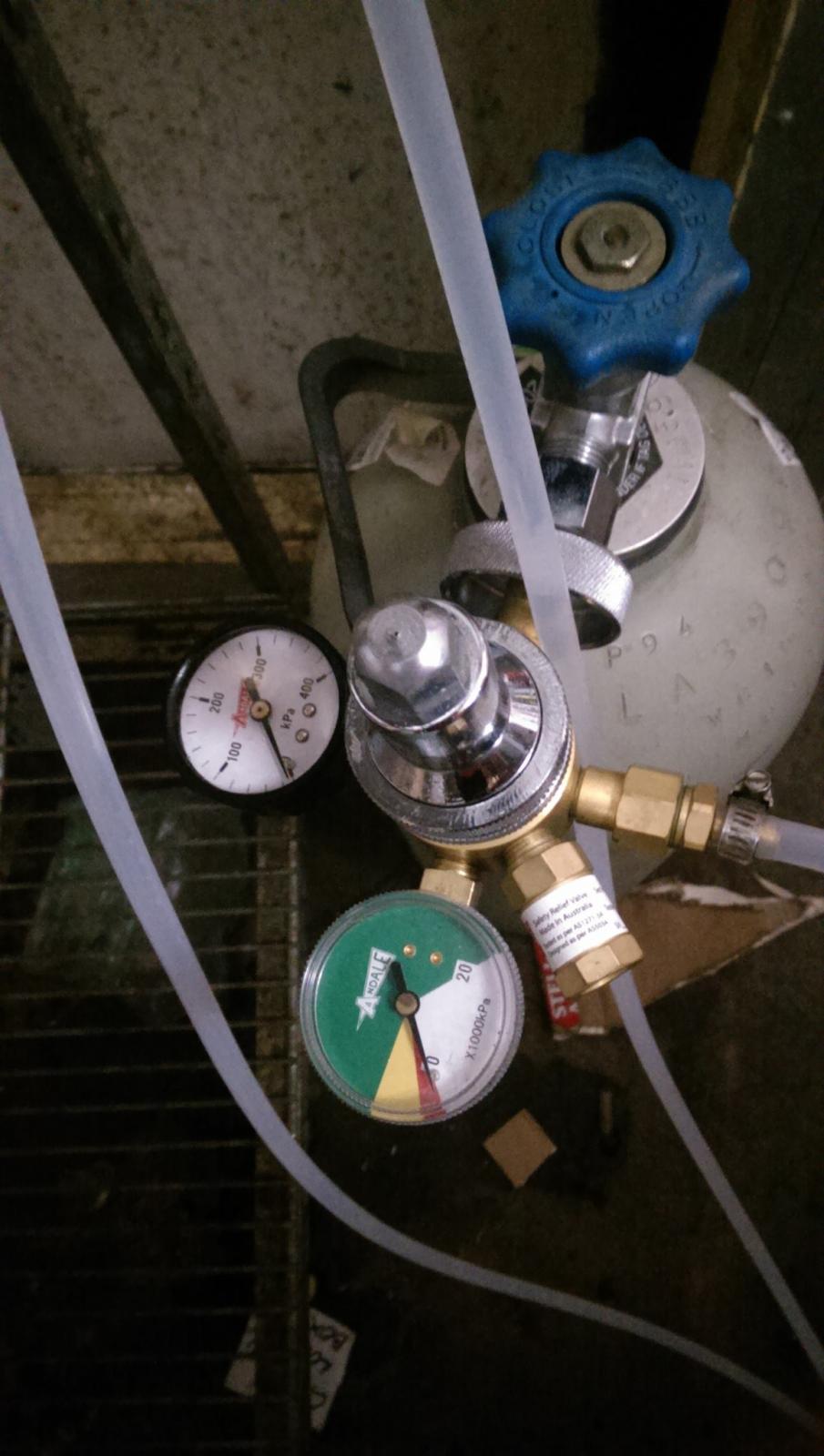

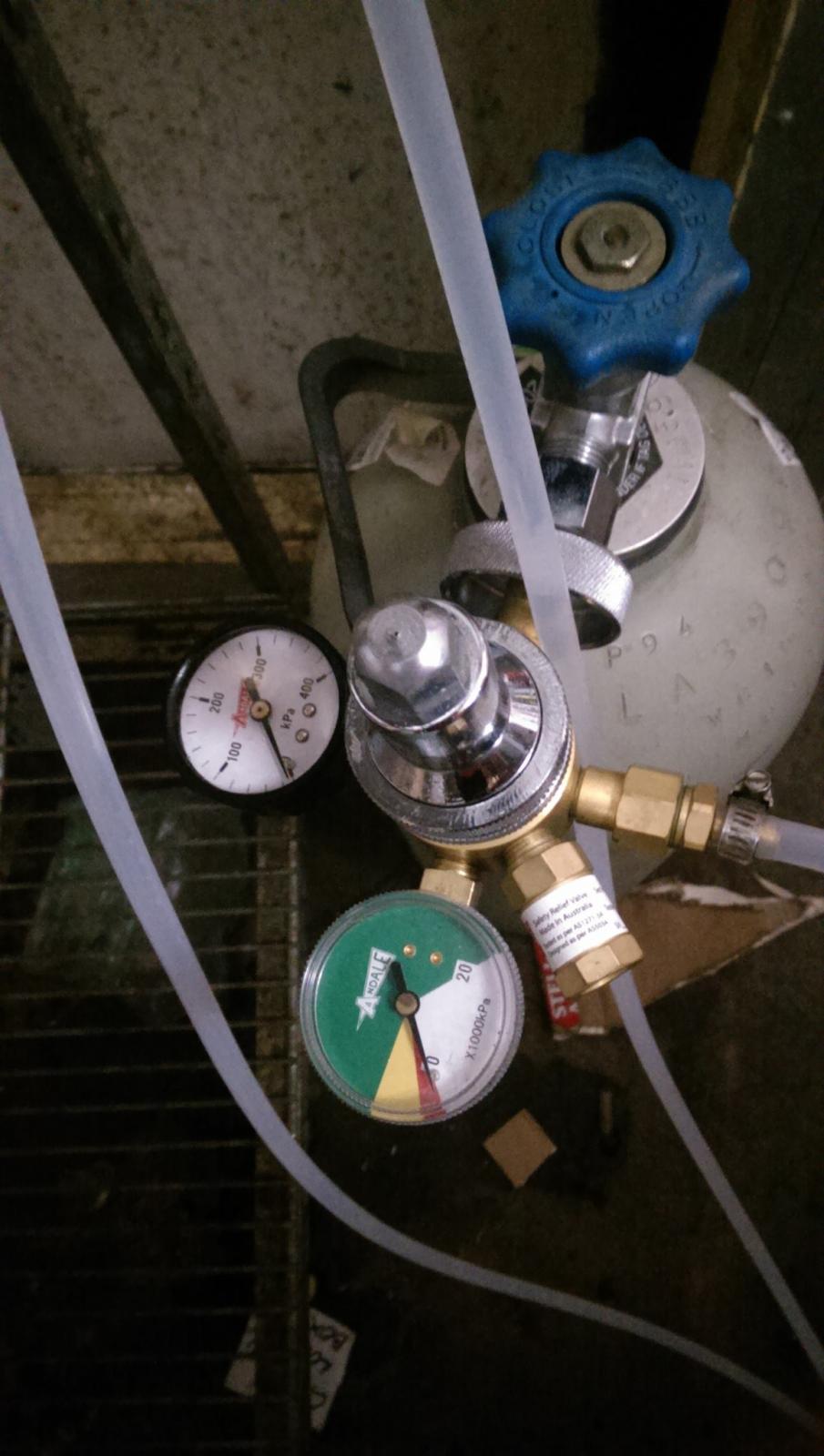

My regulator seems to be working fine and holding pressure well and evenly. I assumed with such foaming that perhaps I was running to high so I've tried it at a vast range of pressures with no change in the foam situation.

I have had to run the lines through the wall of the keg room, up the wall outside and then down the opposite wall... is the rise and fall in gravity and the vertical set up likely to be my problem? My physics is rather week so I apologise if this seems elementary. My flow rate is fine so it's not as though the lines are too long and the pressure isn't sufficient to push the beer at speed. That said, this is all I can think of to be causing my never ending foaming issue.

I'm all out of ideas about what to do.

I would greatly appreciate any help or advice as to what to try next. My boss is breaking my balls about getting this thing finished

Thanks in advance.

I've installed a new beer system at work with two counter pressure filling guns to dispense the beer. Pics are attached. Everything is good to go but I have been testing it and all I am getting through either gun is pure foam.

The beer kegs and gas cylinder are situated in a cool room kept at the same constant temperature. Each line is probably only about 3-4 metres long in total so I don't think temperature change over distance should be too much of an issue?

My regulator seems to be working fine and holding pressure well and evenly. I assumed with such foaming that perhaps I was running to high so I've tried it at a vast range of pressures with no change in the foam situation.

I have had to run the lines through the wall of the keg room, up the wall outside and then down the opposite wall... is the rise and fall in gravity and the vertical set up likely to be my problem? My physics is rather week so I apologise if this seems elementary. My flow rate is fine so it's not as though the lines are too long and the pressure isn't sufficient to push the beer at speed. That said, this is all I can think of to be causing my never ending foaming issue.

I'm all out of ideas about what to do.

I would greatly appreciate any help or advice as to what to try next. My boss is breaking my balls about getting this thing finished

Thanks in advance.