KookyBrewsky

Well-Known Member

- Joined

- Feb 23, 2020

- Messages

- 363

- Reaction score

- 121

Hello all,

New to this hobby and I believe it suits me well. I am diagnosed with schizophrenia and can’t function socially, for this hobby, all I need is myself. I’d love to work for a few years and develop skills further to potentially opening a local brewery but unless I had help I wouldn’t be able to manage the social aspects of it, unless I only sold bottles! I enjoy food though I’m not much of a cook or baker, I love the process of brewing beer so far, which can be a science and an art at the same time. I read a lot prior and ordered quite a few things to get me going, namely a homebrewing.org kit and four extract kits (plus extras like blow off tubing, extra air locks, etc for emergency purposes) before I move onto BIAB brewing which seems to have many fans and opponents. One of the kits I ordered is actually BIAB which I didn’t know, they call it steep-to-convert, it’s a Guava Haze kit. I for one don’t have the space for all-grain at the house. After that I will begin developing my own recipes which I want to focus around the changing seasons.

My first brew is a chocolate stout because I’m first and foremost a coffee+chocolate fanatic, occasionally I’ll roast my own beans but I have a roaster I buy from weekly.

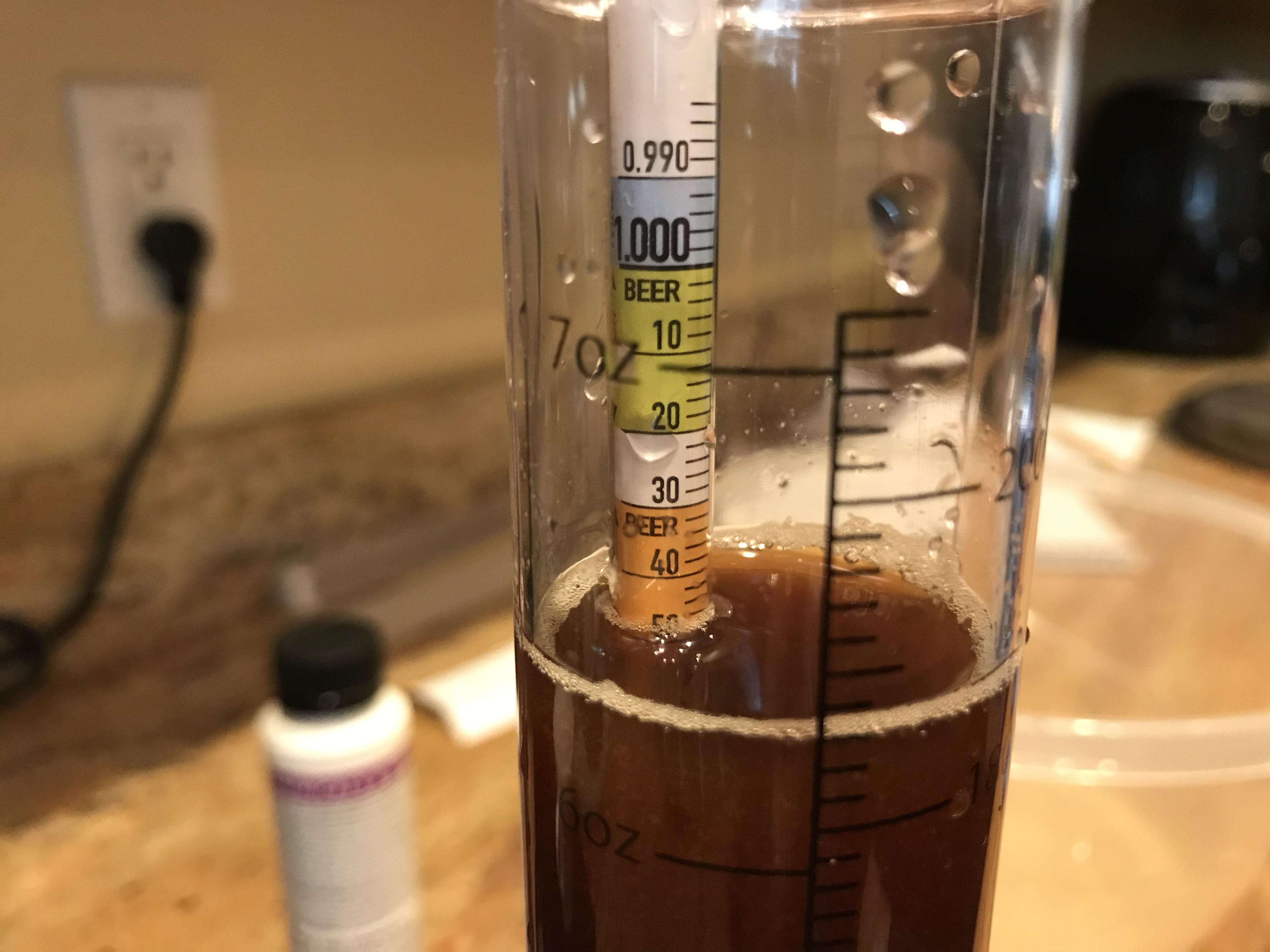

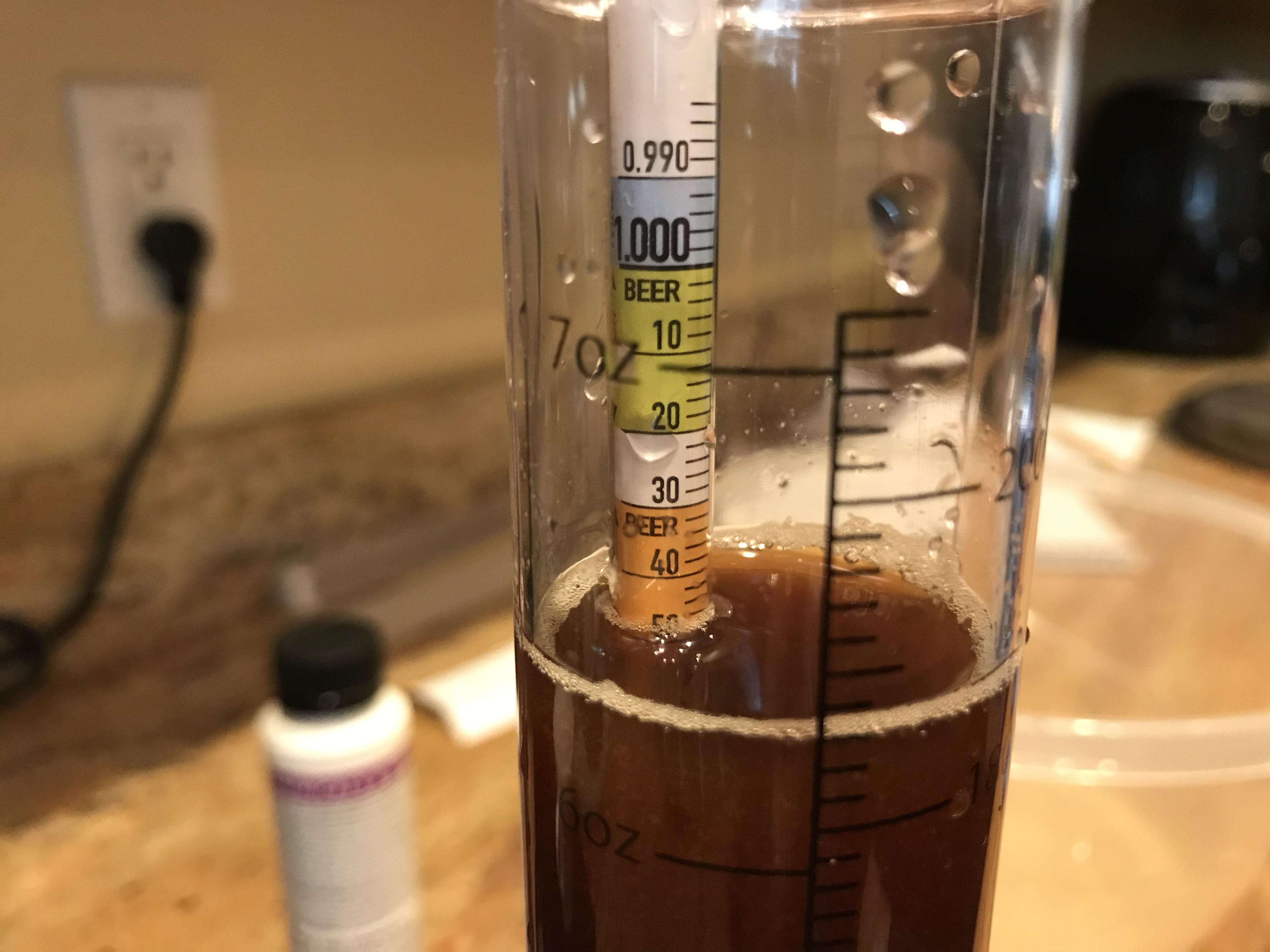

Seems to be going well. It’s currently been two full days as of 2PM EST today, my air lock has some activity, about a bubble a second, although I’ve read pretty consistently it’s not really an indicator of anything, however when I give it a whiff it definitely smells like beer! It had an OG of ~1.048 to ~1.050. The meniscus was was surrounded by bubbles even after spinning the hydrometer.

I have enough space for two brews at a time and over 100 empty bottles on hand. I think on Monday I’ll brew the chipotle porter and hope both turn out well by my birthday late March. It’s always hot in Florida so the only way I can control temp cheaply is to stick a wet towel around the bucket with the tail in a bucket of ice water. Going to Home Depot for a small clip on fan soon.

Will keep updating as to how it turns out and if I have any questions as things develop. Brew day went very smoothly and besides sanitation worries (was everything sanitized enough?) I didn’t have any hiccups.

Cheers

edit : I did forget a hiccup! Water. Our town water is pretty good actually but if I leave it overnight and let it get to room temp it has a pretty chlorinated aroma.. so on brew day I quickly went to the grocery to get gallons of spring water which I used directly, unsanitized, I do hope this doesn’t affect anything. For future brews I have acquired Campden tablets and will simply be using our tap water.

New to this hobby and I believe it suits me well. I am diagnosed with schizophrenia and can’t function socially, for this hobby, all I need is myself. I’d love to work for a few years and develop skills further to potentially opening a local brewery but unless I had help I wouldn’t be able to manage the social aspects of it, unless I only sold bottles! I enjoy food though I’m not much of a cook or baker, I love the process of brewing beer so far, which can be a science and an art at the same time. I read a lot prior and ordered quite a few things to get me going, namely a homebrewing.org kit and four extract kits (plus extras like blow off tubing, extra air locks, etc for emergency purposes) before I move onto BIAB brewing which seems to have many fans and opponents. One of the kits I ordered is actually BIAB which I didn’t know, they call it steep-to-convert, it’s a Guava Haze kit. I for one don’t have the space for all-grain at the house. After that I will begin developing my own recipes which I want to focus around the changing seasons.

My first brew is a chocolate stout because I’m first and foremost a coffee+chocolate fanatic, occasionally I’ll roast my own beans but I have a roaster I buy from weekly.

Seems to be going well. It’s currently been two full days as of 2PM EST today, my air lock has some activity, about a bubble a second, although I’ve read pretty consistently it’s not really an indicator of anything, however when I give it a whiff it definitely smells like beer! It had an OG of ~1.048 to ~1.050. The meniscus was was surrounded by bubbles even after spinning the hydrometer.

I have enough space for two brews at a time and over 100 empty bottles on hand. I think on Monday I’ll brew the chipotle porter and hope both turn out well by my birthday late March. It’s always hot in Florida so the only way I can control temp cheaply is to stick a wet towel around the bucket with the tail in a bucket of ice water. Going to Home Depot for a small clip on fan soon.

Will keep updating as to how it turns out and if I have any questions as things develop. Brew day went very smoothly and besides sanitation worries (was everything sanitized enough?) I didn’t have any hiccups.

Cheers

edit : I did forget a hiccup! Water. Our town water is pretty good actually but if I leave it overnight and let it get to room temp it has a pretty chlorinated aroma.. so on brew day I quickly went to the grocery to get gallons of spring water which I used directly, unsanitized, I do hope this doesn’t affect anything. For future brews I have acquired Campden tablets and will simply be using our tap water.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)