ernestmyname

Well-Known Member

So I made a post on a motorcycle forum about my first brew day. I tried to explain the basics while showing pics of equipment. I would really appreciate it if you guys would glance and see if I am doing any of this stuff completely wrong. First off, next time I brew outside and elevate my cooker enough to allow the draining and cooling to take place outdoors. Unfortunately it rained all weekend and the grain was already ground. So I did it indoors/under the carport.

Pics as promised. Post 1 of 2

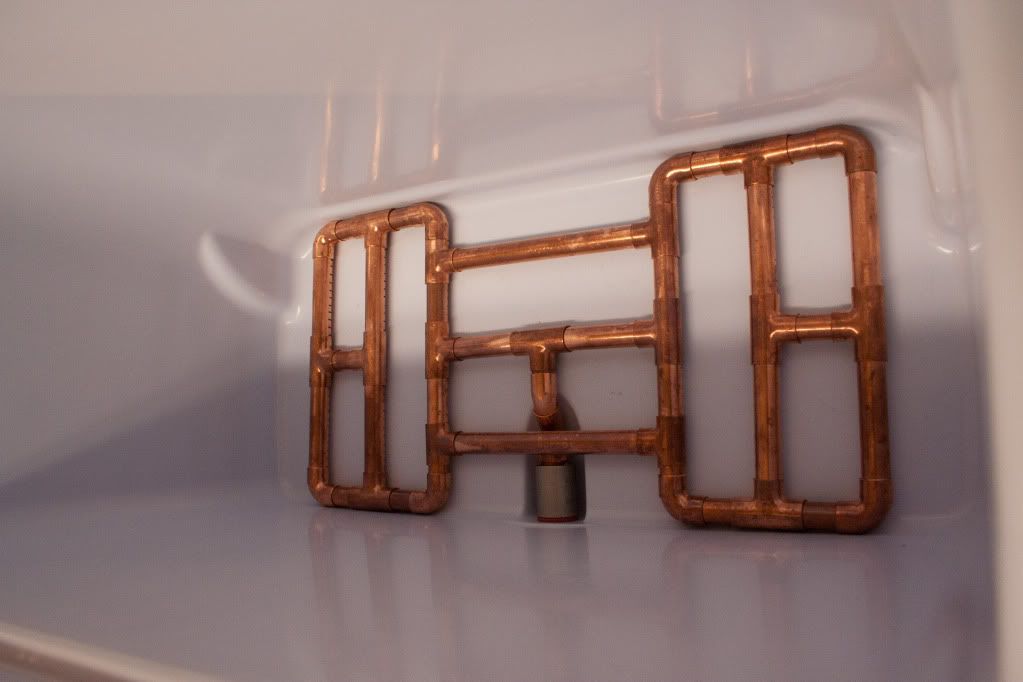

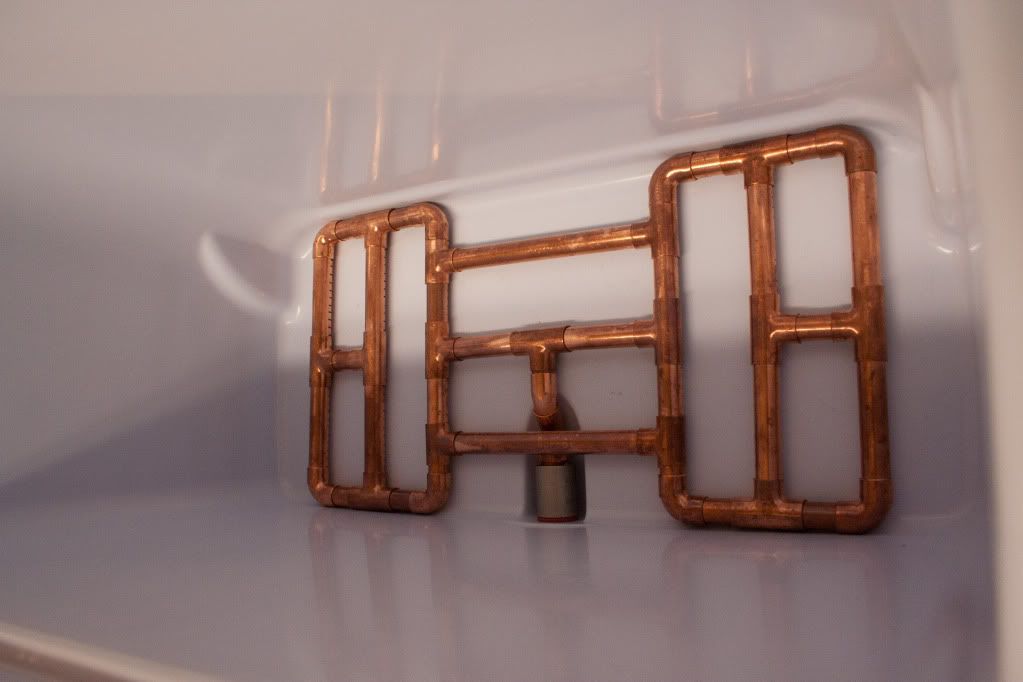

This is the manifold I made.. Majorly overdone but works great. I was able to drain the grain as quickly as I desired. I was also able to get clear runnings after a couple pints of recirculation.

Waiting on water to boil to preheat the tun.

Draining off the pre-heat water.

The preheating was done while this was outside bringing the strike water up to a calculated 164 degrees. When mixed with the room temperature grain the final temp came out to the desired 152F within a degree.

I used a digital temp probe stuck in the tun to give an idea of the inside temp. This eliminated the need to open and close the cooler.

60 minutes later, I drained the grain bed. At this point the product is wort, or unfermented beer. Next brew I'm going to upgrade my tubing to eliminate splashing in the tube. Splashing the beer at this stage introduces oxygen to the wort which is bad.

The mashout step is to bring the grains to a higher temp which helps efficiency and causes the wort to flow easier. This water was heated outside and added to the grain bed. After 10 minutes the grain bed was drained again. Next is to cook the wort.

Hop additions are made at differing time intervals and the chiller is added to the pot 10-15 minutes before the end of the boil to sanitize it. I also add irish moss at the end of the boil to help with clarification.

Next is to bring the wort down to room temp as quickly as possible. Not cooling it quickly enough causes issues with long-term beer stability. When the beer is chilled, proteins precipitate out. If it is not chilled quickly enough, the proteins will not precipitate effectively and cause the finished product to be hazy. Cold water is pumped through the chiller to remove heat from the wort. The inlet and outlet is bent downward so that any leaking water would drip out of the sanitized wort.

Pics as promised. Post 1 of 2

This is the manifold I made.. Majorly overdone but works great. I was able to drain the grain as quickly as I desired. I was also able to get clear runnings after a couple pints of recirculation.

Waiting on water to boil to preheat the tun.

Draining off the pre-heat water.

The preheating was done while this was outside bringing the strike water up to a calculated 164 degrees. When mixed with the room temperature grain the final temp came out to the desired 152F within a degree.

I used a digital temp probe stuck in the tun to give an idea of the inside temp. This eliminated the need to open and close the cooler.

60 minutes later, I drained the grain bed. At this point the product is wort, or unfermented beer. Next brew I'm going to upgrade my tubing to eliminate splashing in the tube. Splashing the beer at this stage introduces oxygen to the wort which is bad.

The mashout step is to bring the grains to a higher temp which helps efficiency and causes the wort to flow easier. This water was heated outside and added to the grain bed. After 10 minutes the grain bed was drained again. Next is to cook the wort.

Hop additions are made at differing time intervals and the chiller is added to the pot 10-15 minutes before the end of the boil to sanitize it. I also add irish moss at the end of the boil to help with clarification.

Next is to bring the wort down to room temp as quickly as possible. Not cooling it quickly enough causes issues with long-term beer stability. When the beer is chilled, proteins precipitate out. If it is not chilled quickly enough, the proteins will not precipitate effectively and cause the finished product to be hazy. Cold water is pumped through the chiller to remove heat from the wort. The inlet and outlet is bent downward so that any leaking water would drip out of the sanitized wort.