Naive of me as I'm brewing tomorrow, first lager in 20 years, and realizing I've not made proper provision for getting wort ideally down to 45 or so. In Wisconsin and our water is cold, but even so, with just one IC, it might take 25 minutes to get to 63, my usual ale pitching temp. I've rigged up a pre-chiller IC but both are only 3/8" x 25', so I'm thinking I'm screwed. I'd go to Home Depot tonight and get a submersible if I thought it would do any good.

The only thing I can think of to do is get the wort to 60F as quickly as possible and maybe transfer it to the glass carboy and immerse the carboy itself in an ice bath, stirring the wort until at the right temp with some sort of boil/sanitized stainless stirring rod; or, put the (sealed) carboy in the fermentation fridge which is currently at 36F, as I've crashed the starter yeast. But I haven't done that since the earliest days (90's), when I simply placed the extract-based, diluted wort outside to cool. My skin crawls at the thought.

Thoughts?

The only thing I can think of to do is get the wort to 60F as quickly as possible and maybe transfer it to the glass carboy and immerse the carboy itself in an ice bath, stirring the wort until at the right temp with some sort of boil/sanitized stainless stirring rod; or, put the (sealed) carboy in the fermentation fridge which is currently at 36F, as I've crashed the starter yeast. But I haven't done that since the earliest days (90's), when I simply placed the extract-based, diluted wort outside to cool. My skin crawls at the thought.

Thoughts?

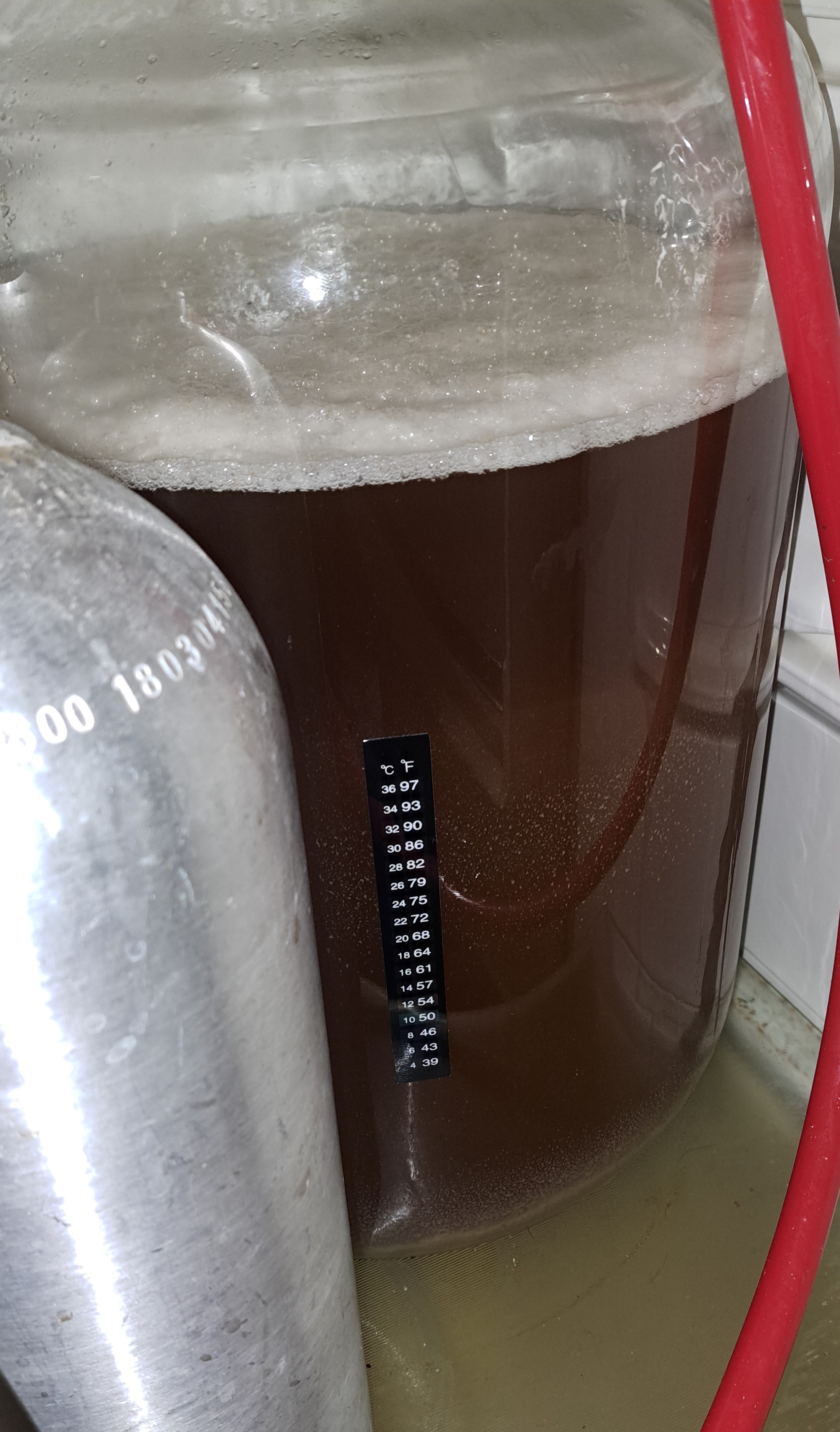

) rocking now.

) rocking now.