Rogue_Atom87

Well-Known Member

- Joined

- Sep 3, 2020

- Messages

- 134

- Reaction score

- 27

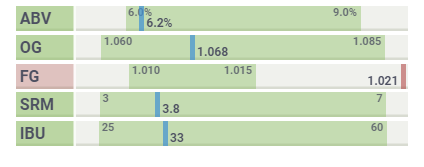

Yeah I dont know why I had whirlfloc down in recipe. I removed that as not needed. After updating my equipment profile the FG drifted quite a bit. I have efficiency set at 70%. Not sure if 1.021FG will be ok based on this recipe. Below is what Brewfather was calculating

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)