interference

Member

- Joined

- Jan 1, 2016

- Messages

- 10

- Reaction score

- 1

Hi Long time Drinker, First time Brewer here,

Lots of great information here.

I guess I'm looking for warm hope as I bottle this stuff anyway, right?

I've done a lot of my reading after putting my first batch in the fermenting bucket. Well I've let it sit with a weighted down piece of plastic, going with the CO2 positive pressure sealant method, on top of the bucket since I brewed it on New Year's Eve. So over 2 weeks ago. I figured I knew I would procrastinate my way into letting it sit for at least 2 weeks, so it seemed to me that taking gravity readings would introduce more problems than in might solve.

I've been smelling around the top of the bucket and its been smelling good I guess, like flat beer. So I finally took the lid off tonight, just to see (*next time I'm using a see through piece!) and was a little bummed to get a slight whiff of vinegar. It's been in a shaded closet that I imagine has a temperature range of 60 to 80 degrees F.

Here's the picture.

*click for larger version*

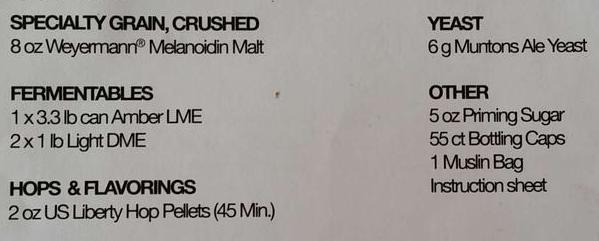

The krausen seems to have formed and dropped. This is a 5 gal extract brew, here are the ingredients if you are curious.

Should I bottle right away since CO2 production has probably slowed? Thanks for any input or guiding questions you might have.

Lots of great information here.

I guess I'm looking for warm hope as I bottle this stuff anyway, right?

I've done a lot of my reading after putting my first batch in the fermenting bucket. Well I've let it sit with a weighted down piece of plastic, going with the CO2 positive pressure sealant method, on top of the bucket since I brewed it on New Year's Eve. So over 2 weeks ago. I figured I knew I would procrastinate my way into letting it sit for at least 2 weeks, so it seemed to me that taking gravity readings would introduce more problems than in might solve.

I've been smelling around the top of the bucket and its been smelling good I guess, like flat beer. So I finally took the lid off tonight, just to see (*next time I'm using a see through piece!) and was a little bummed to get a slight whiff of vinegar. It's been in a shaded closet that I imagine has a temperature range of 60 to 80 degrees F.

Here's the picture.

*click for larger version*

The krausen seems to have formed and dropped. This is a 5 gal extract brew, here are the ingredients if you are curious.

Should I bottle right away since CO2 production has probably slowed? Thanks for any input or guiding questions you might have.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)