You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FG 1.022?

- Thread starter odie

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Homergah

Only I didn't say fudge

What yeast? What OG?Had a brown ale with 20 oz of salted caramel baking mix, pretty much pure sugar...after 2 weeks at 68’ it’s stuck at 1.022? Way higher than I was thinking. Any chance there is a lot of unfermentables?

tgolanos

Well-Known Member

What was your grain bill, mash, and fermentation process (assuming all-grain)? The more specifics you can give, the more likely someone can pinpoint any issues.

thehaze

Well-Known Member

Isn't Muntons dry yeast something like Windsor, aka. low attenuator? I could be wrong, but it would explain the high FG. If similar to Windsor, 1.022 is exactly right and will not pose problems. Windsor is actually quite pleasent at high FG.

odie

Well-Known Member

Grain bill. 7# 2 row domestic pale, 1# caramunich 1, 0.5 crystal 75, 0.5# brit crystal 135/165, 20oz of salted caramel mix melted in a pan with a little leftover wort and pitched in fermenter. 68’ in a controlled fridge. After 2 weeks the last few days activity just bottomed out. I probably could have left it another week but had to move an ESB in. I’m gonna leave the keg at room temp a few days and maybe get a little more activity an drop a couple more points?

odie

Well-Known Member

It is entirely possible my OG was off cause I pitched the caramel sugars in the ferm and just kind shook it a little. Guess Not really a best practice for getting uniform density [emoji53]. But figured the yeasties would find it anyway. It was 1.058 before adding the caramel

You've got 2 pounds of crystal malt in that recipe, 22%. That's quite a bit of unfermentables.

Caramel (semi-pyrolyzed sugar) is not very fermentable, and may contain maltodextrin which is non-fermentable.

Most British yeasts can't ferment maltotriose, leaving their characteristic sweetness.

Have you tasted it yet? You may be surprised how good it is, even being a bit sweeter than you intended.

Or non-fermentable sugar. How would you know?20 oz of salted caramel baking mix, pretty much pure sugar

Caramel (semi-pyrolyzed sugar) is not very fermentable, and may contain maltodextrin which is non-fermentable.

Most British yeasts can't ferment maltotriose, leaving their characteristic sweetness.

Have you tasted it yet? You may be surprised how good it is, even being a bit sweeter than you intended.

Did you add the mix at start of fermentation? Cause typically with simple sugars it's better practice to boil them separately and add once primary fermentation is done to avoid the yeast going after the simple chain molecule sugars first which can lead to stalled fermentations.

Rev.

Rev.

odie

Well-Known Member

Alright, that caramel crunch^ is mostly simple sugars and should thus be mostly fermentable.

Must be the 22% of cara/crystal malts and the yeast.

Must be the 22% of cara/crystal malts and the yeast.

Theredsasquatch

Member

- Joined

- Dec 8, 2015

- Messages

- 16

- Reaction score

- 2

Try pitching two packs of a hight attenuation yeast like us05, I bet it would drop a few points after another week

I agree with this. I have used lager yeast like this a couple of times. 60f or so will be fine because there isn't that much sugar left (relatively). It won't taste like sulphur or produce esters just finishing this last bit of sugar. On an experimental beer, I used a lavlin 71b -1112 in a California common with 15% Crystal malt down to 1.020. That is about all 71b can do to beer. I then the carbonated the batch in the bottle with Saflager W34/70. It brought the gravity down to 1.014 ...13 about- letting one degass overnight. Another time I just fixed a batch that got too cold by racking into a secondary on top of San Francisco Lager yeast. Original yeast was Muntons Gold to 1.028 or so. About Muntons- it is very flocculant, I have never suspected it to be Windsor. It will under attenuate if it drops too early.Try pitching two packs of a hight attenuation yeast like us05, I bet it would drop a few points after another week

odie

Well-Known Member

Well it’s already in the keg in the fridge. Is it too late to pull it out and let if sit at room temperature for another week or two? Either with some fresh yeast or let the Mutons wake up and try to finish it? Or is that not really a great yeast?

Northern_Brewer

British - apparently some US company stole my name

Original yeast was Muntons Gold to 1.028 or so. About Muntons- it is very flocculant, I have never suspected it to be Windsor.

Muntons Gold and Muntons "ordinary" are different yeasts. The ordinary one, which appears to be derived from the old EDME homebrew yeast like Windsor and S-33, is a low attenuator like Windsor.

I've not used the Gold and I don't think it's been sequenced, but my working assumption would be that it's another derivative of Nottingham, as Muntons appear to make a Nottingham derivative for their white-label clients. Might be S-04 or something though.

So yep, >20% crystal/cara won't help your attenuation, and frankly just the thought of that much crystal rather puts me off the beer. But the first thing to do is to taste it - taste is more important than numbers, and it's hard to predict what will suit some people's tastes. If it tastes good then don't worry about it.

Sounds like you are close. Let it ride another week or two. I did a Black maple IPA the used 7 gallons of fresh maple sap. Took 6 months to hit 1.010 Fg.

Sorry to thread hijack but curious how this turned out? I had a beer made with all maple tree sap at Liquid Riot in Portland,ME years back and it was fantastic. I’ve never seen anyone else do this at pro/homebrew level.

It turned out ok as an IPA. Problem we had was carbonation. It was all low then after we had a freeze the beer was suddenly carbonated. In my new recipe I will be adjusting it to cold store/crash as if was a lager. Wonder if that would change it to a lager ipa. I suspect commercially it could only be produced as small batch due to the chemical make up of the sap. That changes from tree to tree and from plot to plot and even season to season so you would either need millions of gallons of sap or stick with smaller batches.Sorry to thread hijack but curious how this turned out? I had a beer made with all maple tree sap at Liquid Riot in Portland,ME years back and it was fantastic. I’ve never seen anyone else do this at pro/homebrew level.

odie

Well-Known Member

Muntons Gold and Muntons "ordinary" are different yeasts. The ordinary one, which appears to be derived from the old EDME homebrew yeast like Windsor and S-33, is a low attenuator like Windsor.

I've not used the Gold and I don't think it's been sequenced, but my working assumption would be that it's another derivative of Nottingham, as Muntons appear to make a Nottingham derivative for their white-label clients. Might be S-04 or something though.

So yep, >20% crystal/cara won't help your attenuation, and frankly just the thought of that much crystal rather puts me off the beer. But the first thing to do is to taste it - taste is more important than numbers, and it's hard to predict what will suit some people's tastes. If it tastes good then don't worry about it.

yeah that is a lot of crystal...but it's what the recipe said...well I used what I had that was "close"...meaning 0.5# 75 crystal vise 60 and 0.5# 135/165 vice 120...so that was "over"...but the other crystal was the caramunich and I had 1# 39L vice 50L so was a tad bit "under"...and the last caramel malt in the recipe 1# (60L) was totally skipped in favor of 20oz of sugar caramel baking mix...

So I am a bit "off recipe"...and I used the regular Muntons...I really don't know what to truly expect on taste...I was just intrigued by the salted caramel...and the local brew pub has a "salted caramel" on tap but I don't think they did it this way...

odie

Well-Known Member

I got a gallon of maple syrup that is planned for a stout...not sure how I'll work it yet...Sounds like you are close. Let it ride another week or two. I did a Black maple IPA the used 7 gallons of fresh maple sap. Took 6 months to hit 1.010 Fg.

I do a maple porter. If you want the maple hint add it to the secondary. I found when added to primary it really only increased the final ABV and only faintly had maple taste.I got a gallon of maple syrup that is planned for a stout...not sure how I'll work it yet...

odie

Well-Known Member

yeah, that's what I've read on other posts as well...thus is my likely course of action...I do a maple porter. If you want the maple hint add it to the secondary. I found when added to primary it really only increased the final ABV and only faintly had maple taste.

at what point in the secondary? at transfer or some point before bottle/keg? Not sure if I should liquefy the syrup in some of the beer from the pri on a stove top and then blend into the secondary at transfer...or just pour the syrupy goo into the secondary and let the yeast find it?

and I have pure maple syrup from the grocery, not raw sap...

so how much syrup do you think?

yeah, that's what I've read on other posts as well...thus is my likely course of action...

at what point in the secondary? at transfer or some point before bottle/keg? Not sure if I should liquefy the syrup in some of the beer from the pri on a stove top and then blend into the secondary at transfer...or just pour the syrupy goo into the secondary and let the yeast find it?

and I have pure maple syrup from the grocery, not raw sap...

so how much syrup do you think?

When I use maple syrup and jump to the secondary when the gravity is at about halfway, for me that has been about two weeks with the porter. Now for me I have a conical so primary and secondary are in the same unit and the only way to really define it is when I remove the collection ball it is to clean out all the trub and start the yeast collection. That is when I add the maple syrup.

With the syrup I would recommend placing the container it is in, in hot tap water to thin, same as what I do for mead. Don't bother to heat the syrup remember it is only a few degrees from becoming candy. The hot water for about 30 minutes and add it to the wort. Usually around 80 degrees, nothing hotter.

You will benefit from a good stir with the syrup, otherwise it will cool fast and sink to the bottom. Make sure everything is clean and sanitized because with stouts and porters lacto infection can happen, but for me I see that is as a good thing (that is another story). How much to add is up to you. I use 8 cups of grade AA syrup (half gallon) for five gallons of wort. You are not going to gain much in fermentable sugars from syrup as you would with sap but aging it for a few months, cold crash to settle out the yeast for a day or two, should yield a pretty good batch.

odie

Well-Known Member

salt...hmm... slow but not kill? I gotta go back and check the salt content on the label...

sounds like another vote to let the ferment continue?

But since it's already getting carbed and cold...is it possible to take it out and warm it back up and let the yeast continue, or pitch some additional yeast? Unusual method but I would think possible...

after a sample taste tonight at least..lol

sounds like another vote to let the ferment continue?

But since it's already getting carbed and cold...is it possible to take it out and warm it back up and let the yeast continue, or pitch some additional yeast? Unusual method but I would think possible...

after a sample taste tonight at least..lol

What did you mash at, temp wise? and there's always the overkill route, and adding gluco...

how many pounds of that sugar did you add? could just have gotten enough alcohol to crap out the yeast...

edit: but probably not, you'd have to add something like 5 lbs....

how many pounds of that sugar did you add? could just have gotten enough alcohol to crap out the yeast...

edit: but probably not, you'd have to add something like 5 lbs....

Last edited:

odie

Well-Known Member

What did you mash at, temp wise? and there's always the overkill route, and adding gluco...

how many pounds of that sugar did you add? could just have gotten enough alcohol to crap out the yeast...

edit: but probably not, you'd have to add something like 5 lbs....

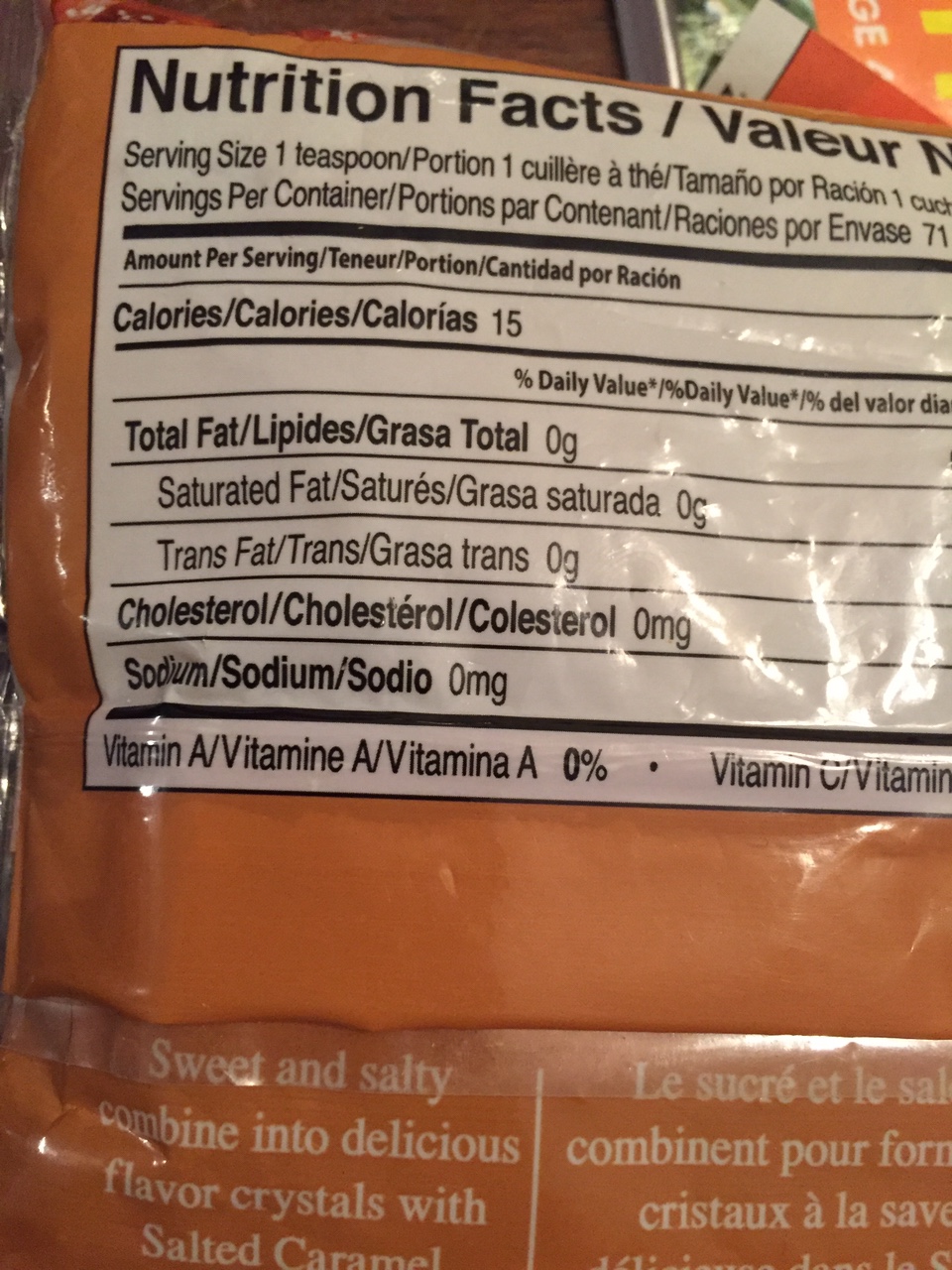

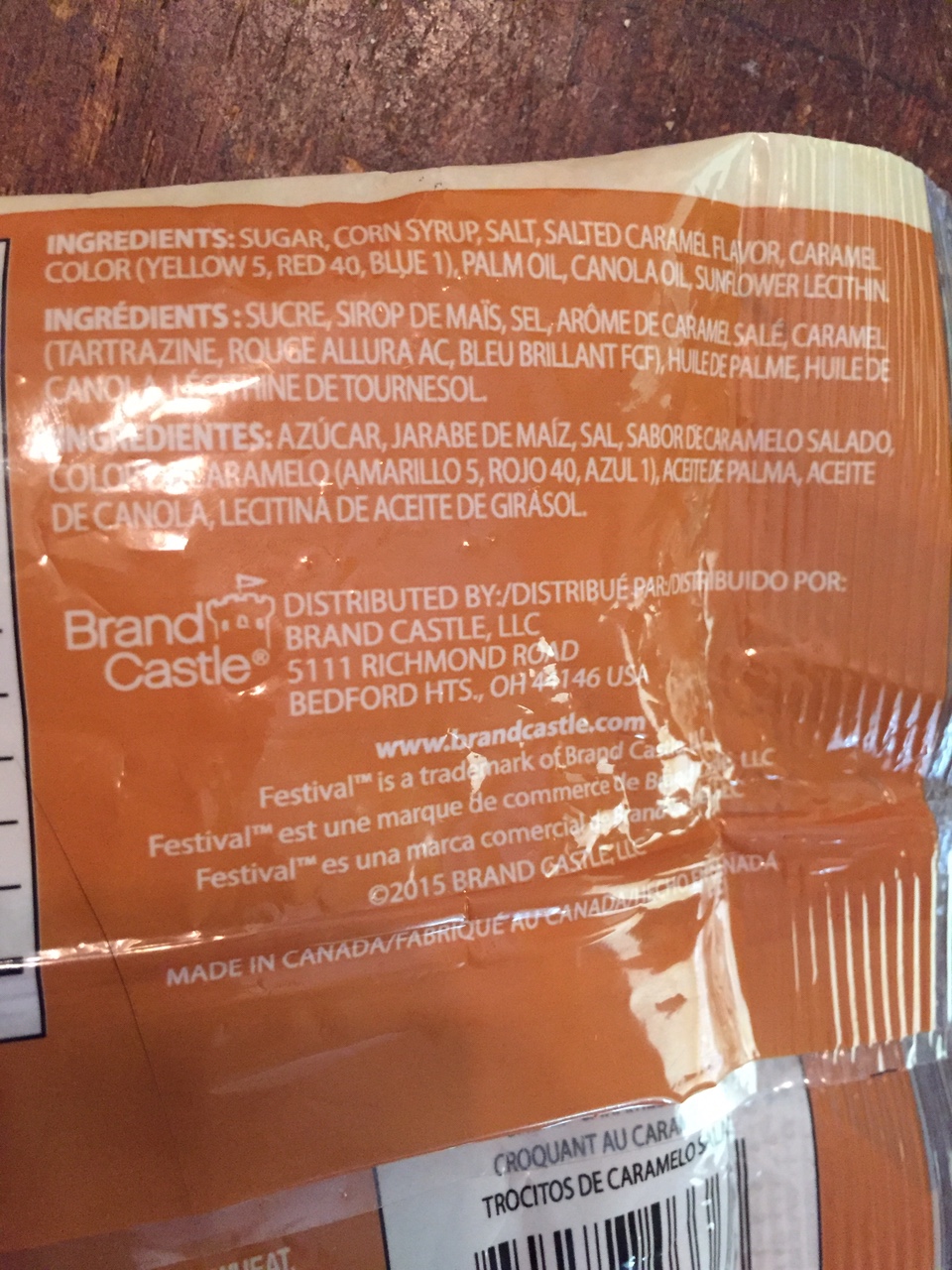

It’s definitely not high in alcohol. 15 oz sugar if I’m reading the nutritional label right. Mash was low 150s? Strike was 168 but didn’t measure the mash...I know [emoji53]

odie

Well-Known Member

When I use maple syrup and jump to the secondary when the gravity is at about halfway, for me that has been about two weeks with the porter. Now for me I have a conical so primary and secondary are in the same unit and the only way to really define it is when I remove the collection ball it is to clean out all the trub and start the yeast collection. That is when I add the maple syrup.

With the syrup I would recommend placing the container it is in, in hot tap water to thin, same as what I do for mead. Don't bother to heat the syrup remember it is only a few degrees from becoming candy. The hot water for about 30 minutes and add it to the wort. Usually around 80 degrees, nothing hotter.

You will benefit from a good stir with the syrup, otherwise it will cool fast and sink to the bottom. Make sure everything is clean and sanitized because with stouts and porters lacto infection can happen, but for me I see that is as a good thing (that is another story). How much to add is up to you. I use 8 cups of grade AA syrup (half gallon) for five gallons of wort. You are not going to gain much in fermentable sugars from syrup as you would with sap but aging it for a few months, cold crash to settle out the yeast for a day or two, should yield a pretty good batch.

Really? I figured maple syrup would be loaded? I thought that’s why it goes in the secondary cause the yeast levels are down. I’ve heard in the primary the syrup pretty much is totally consumed, leaving little if any maple.

It’s definitely not high in alcohol. 15 oz sugar if I’m reading the nutritional label right. Mash was low 150s? Strike was 168 but didn’t measure the mash...I know [emoji53]

i usually only use 162f strike water for 20lb's of grain and 7 gals of water, and get low to mid 150's?

was the grain maybe warmer for this batch then the last one?

Really? I figured maple syrup would be loaded? I thought that’s why it goes in the secondary cause the yeast levels are down. I’ve heard in the primary the syrup pretty much is totally consumed, leaving little if any maple.

Yes it contains some fermentable sugar as a syrup but then again not all sugars are fermentable.

Here is a great article from BYO on sugars. Down towards the middle of the article is Maple Syrup.

https://byo.com/article/sweetness-brewing-sugars-how-to-use-them/

Northern_Brewer

British - apparently some US company stole my name

yeah that is a lot of crystal...but it's what the recipe said...So I am a bit "off recipe"...and I used the regular Muntons

This recipe is a good example of US brewers' bizarre fascination with crystal - they seem to use far more of it than British brewers ever do, and they seldom seem to balance it with sugar as happens in Britain. But even by US standards, this recipe you've found is pretty extreme - in Ray Daniels' book he puts the average American Brown in second-round NHC at 10% crystal, 2% chocolate, 1% black.

So you've an extreme amount of crystal. And then you've use a yeast with less attenuation than the 75% assumed by the author. Admittedly, that's on the high side for WLP002 but even so, the recipe author was assuming more attenuation than you got.

Could be potassium chloride. It's a salt also and is what is used in salt for people who have to limit sodium intake.View attachment 609615View attachment 609616 apparently sodium free salt? Salt is on the ingredients but lacking on the analysis?

odie

Well-Known Member

This recipe is a good example of US brewers' bizarre fascination with crystal - they seem to use far more of it than British brewers ever do, and they seldom seem to balance it with sugar as happens in Britain. But even by US standards, this recipe you've found is pretty extreme - in Ray Daniels' book he puts the average American Brown in second-round NHC at 10% crystal, 2% chocolate, 1% black.

So you've an extreme amount of crystal. And then you've use a yeast with less attenuation than the 75% assumed by the author. Admittedly, that's on the high side for WLP002 but even so, the recipe author was assuming more attenuation than you got.

Damn. So I chose a crappy brown ale recipe to start with? I’ve never done a brown ale, really not my thing...with a couple exceptions

odie

Well-Known Member

Well I tried something novel...pulled the keg out, tapped 2 quarts into a saucepan and put about a pound of DME, warmed up and dissolved it all then back into the keg with a blow off tube...after the bubbles quit recarbonated and chilled...tasted pretty good I think...FG went up to about 1.027...but it’s good

Similar threads

- Replies

- 17

- Views

- 1K

- Replies

- 12

- Views

- 648