For those of you that do small(er than normal) batches, what do you ferment in? I like bucket fermenters because they're easy to clean and block light, but all I'm seeing are 1 gallon, and 5+ gallon buckets.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fermenter for 2.5 gallon batches

- Thread starter Calypso

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

A 5 gal bucket would have too much headspace. You can get 3.5 gal plastic buckets from Uline, but I don't know if they are food-safe.

Another possibility is a 3 gal carboy. I sometimes do 2.5 gal batches and the 3 gal glass isn't as unwieldy as the full size carboys.

Another possibility is a 3 gal carboy. I sometimes do 2.5 gal batches and the 3 gal glass isn't as unwieldy as the full size carboys.

chickypad

lupulin shift victim

I mostly use 3 gal better bottles but I have used the 4.25 gal buckets like you can get from donut shops and bakeries.

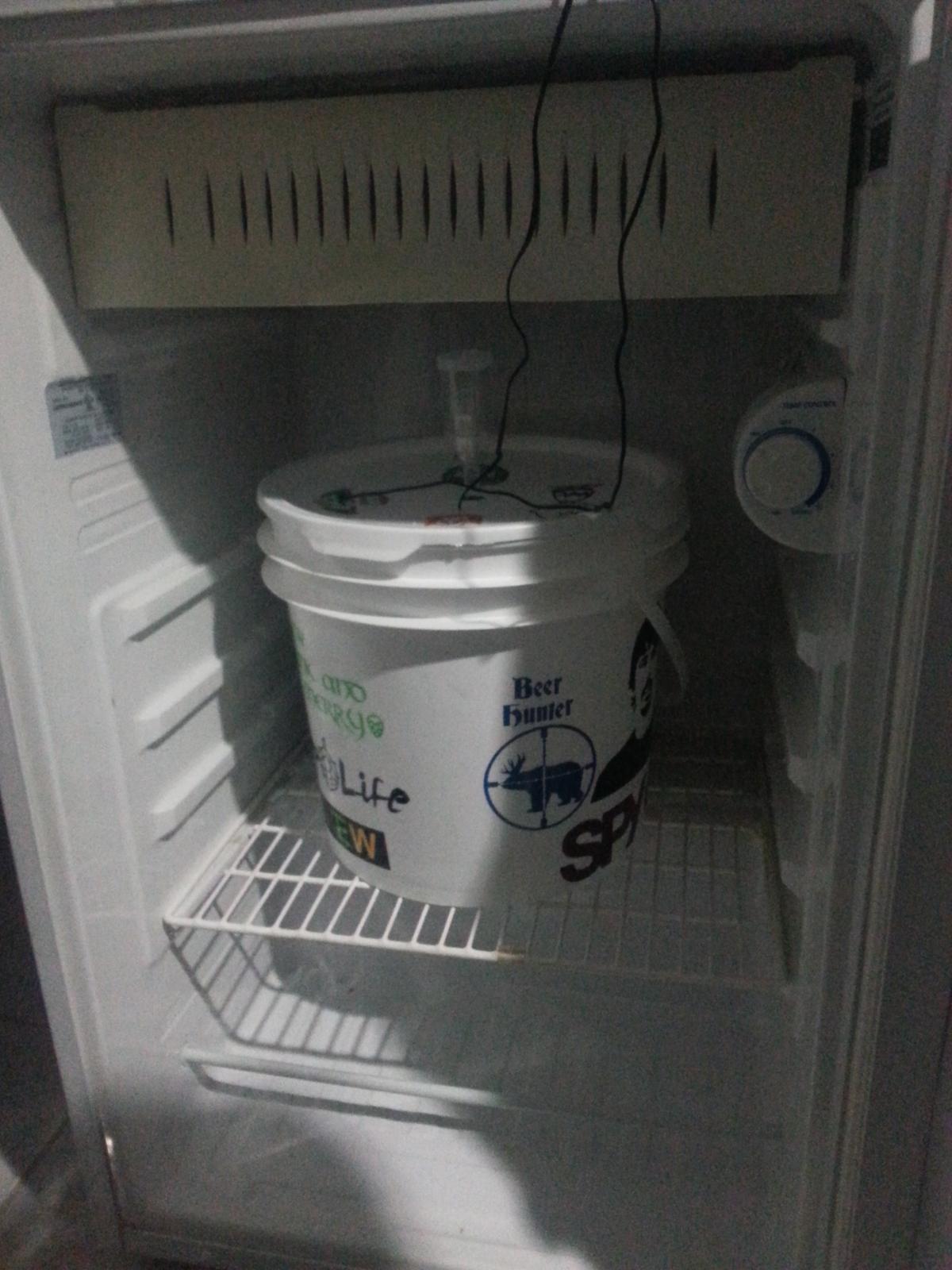

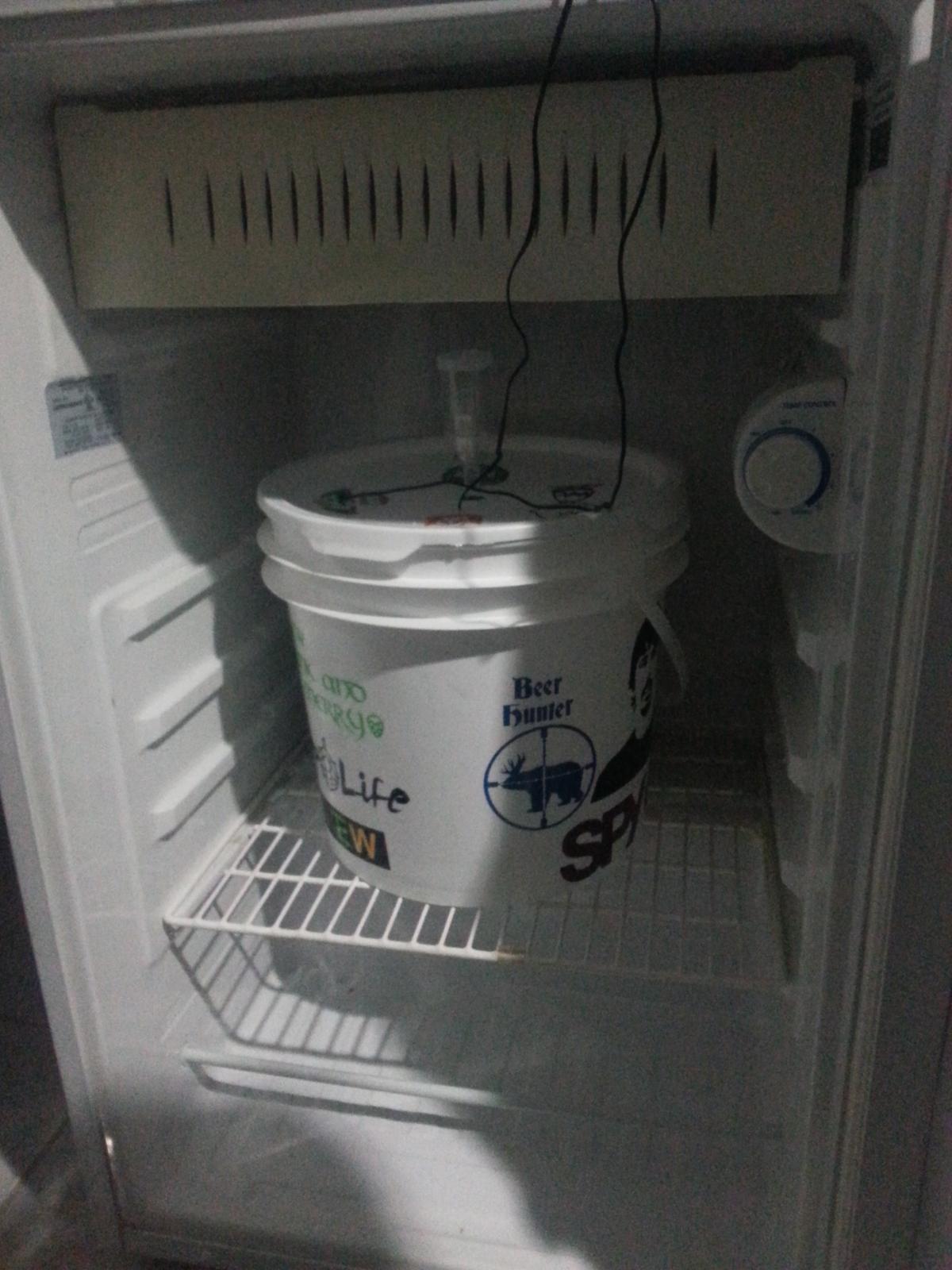

Better Bottle makes three-gallons. They look like this. View attachment ImageUploadedByHome Brew1438611597.164800.jpg

joe_four_strings

Well-Known Member

I have a 3.5gal bucket I got on eBay and a 3gal PET botle bought at the lhbs.

SpeedYellow

Well-Known Member

I like my 3 gal glass carboy for small batches.

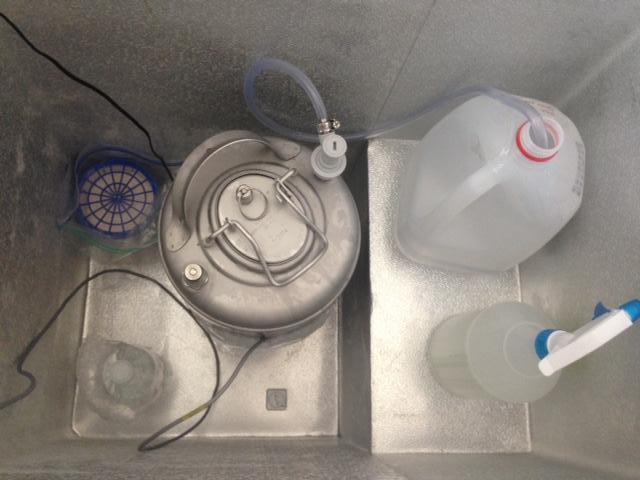

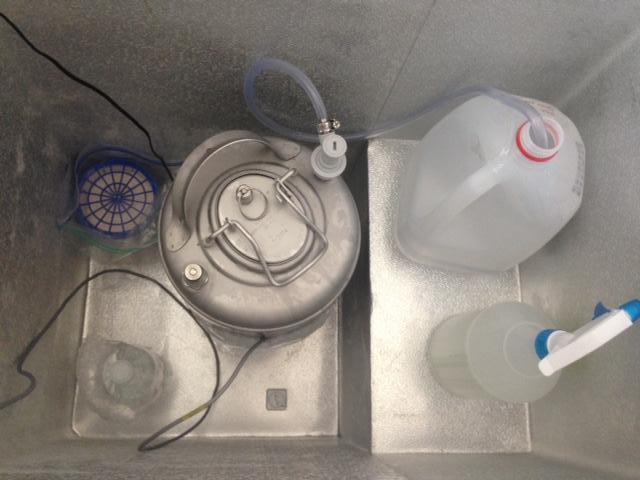

Use a 3 gallon corny keg!

I ferment slightly larger than 3 gallon batches in 3 gallon corny kegs, so my fermenting keg is filled past the weld line almost to the top. I use the gas-in to connect to a blowoff tube - I removed the poppet valve from the gas post as well as the one from the gas quick disconnect to prevent them from clogging with blowoff.

After fermentation slows and there's no more danger of blowoff, I replace the poppetless gas post with a regular one and attach an adjustable pressure relief valve, aka a spunding valve. I set this to 15 psi and let the beer carbonate itself as it finishes fermenting. I brew mostly lagers, so at 50ish degrees 15 psi is enough to mostly carb the beer. If you brew ales, you'll need 25-30 psi at ale ferm temps to reach 2.5 volumes of CO2. However, going much past 15 psi can be detrimental to yeast health, so if you brew an ale you can just let it finish carbing in the serving keg.

I cut the keg's dip tube so that the end floats about an inch and a half off the bottom of the keg. I can rack the fermented beer off the yeast cake into a clean serving keg either by pushing it with CO2, or by using a closed siphon (my preferred method). Take the fermenting keg and put it on a table, then take a clean, CO2 purged keg and put it on the floor. Pressurize the clean keg to the same pressure as the fermenting keg, connect gas to gas and liquid to liquid across the kegs, then release a tiny bit of pressure from the destination keg to start the siphon. You may have to briefly disconnect the gas line while starting the siphon.

I moved to using this method after getting frustrated with both glass and plastic. Stainless steel has the sanitary benefits of glass but without the safety hazards, and corny kegs are ridiculously easy to take apart and clean. Now, my beer stays in a completely closed, oxygen-free environment from fermenter to glass, and as a bonus the beer is carbonated when it's done fermenting!

I ferment slightly larger than 3 gallon batches in 3 gallon corny kegs, so my fermenting keg is filled past the weld line almost to the top. I use the gas-in to connect to a blowoff tube - I removed the poppet valve from the gas post as well as the one from the gas quick disconnect to prevent them from clogging with blowoff.

After fermentation slows and there's no more danger of blowoff, I replace the poppetless gas post with a regular one and attach an adjustable pressure relief valve, aka a spunding valve. I set this to 15 psi and let the beer carbonate itself as it finishes fermenting. I brew mostly lagers, so at 50ish degrees 15 psi is enough to mostly carb the beer. If you brew ales, you'll need 25-30 psi at ale ferm temps to reach 2.5 volumes of CO2. However, going much past 15 psi can be detrimental to yeast health, so if you brew an ale you can just let it finish carbing in the serving keg.

I cut the keg's dip tube so that the end floats about an inch and a half off the bottom of the keg. I can rack the fermented beer off the yeast cake into a clean serving keg either by pushing it with CO2, or by using a closed siphon (my preferred method). Take the fermenting keg and put it on a table, then take a clean, CO2 purged keg and put it on the floor. Pressurize the clean keg to the same pressure as the fermenting keg, connect gas to gas and liquid to liquid across the kegs, then release a tiny bit of pressure from the destination keg to start the siphon. You may have to briefly disconnect the gas line while starting the siphon.

I moved to using this method after getting frustrated with both glass and plastic. Stainless steel has the sanitary benefits of glass but without the safety hazards, and corny kegs are ridiculously easy to take apart and clean. Now, my beer stays in a completely closed, oxygen-free environment from fermenter to glass, and as a bonus the beer is carbonated when it's done fermenting!

joe_four_strings

Well-Known Member

Where'd you get the bucket?

got it from this guy on ebay. He doesn't list them any more, tho.

http://www.ebay.com/usr/hannibals9fresh*ideas?_trksid=p2060353.m2749.l2754

If your lhbs doesn't have them they can prolly order for you, it'll save you the shipping costs which can be high due to size of box. Midwest, northern brewer, etc have the carboys in plastic 3 gal for usually around 20 bucks if you want to get it there. eBay or the inter webs if you want a bucket. Be ready for shipping to be as much or more than product price though. Not heavy, just bulky.

Calypso

Well-Known Member

I use 3 gallon glass carboys but I'm totally jelly of @dfhar and his keg fermentation setup.

Yeah, no kidding. When I have some scratch (and extra space) I'll have to consider a similar setup.

check local grocery store bakeries. I got a frosting bucket for free that holds 3.5-4 gallons...perfect for 2.5-3 gallon batches. They are labeled by weight (of the frosting) not volume...you want the 40 lb bucket.

sputnam

Well-Known Member

I use 5 gallon carboys, no more blow off tube for me. It also allows me to make a little extra and I keep my siphon on the hump so I get minimal trub.

Brew Demon 2.5 gallon conical works for me.

http://www.amazon.com/dp/B00DCC50BC/?tag=skimlinks_replacement-20

http://www.amazon.com/dp/B00DCC50BC/?tag=skimlinks_replacement-20

Last edited by a moderator:

I use 3-gallon glass carboys, or 4-gallon plastic (PET) carboys and just have lots of headspace.

You can get 3-gallon plastic carboys at Walmart. They look kind of hard to clean with the hollow handle molded in.

Or use multiple 1-gallon glass jugs.

You can get 3-gallon plastic carboys at Walmart. They look kind of hard to clean with the hollow handle molded in.

Or use multiple 1-gallon glass jugs.

I bought 3.5 gal buckets from uline with their ez-peel lids and I LOVE them. I originally bought 5 and was going to pass along some of them... but now I'm using all of them because they're so easy to use. They ARE food safe and durable. The lids seal well and are easier to remove than some of the other lids I have to use a tool on.

It's basically all the good stuff about buckets combined with the good stuff about plastic carboys.

More info in the now-defunct for sale post:

https://www.homebrewtalk.com/showthread.php?t=537323

It's basically all the good stuff about buckets combined with the good stuff about plastic carboys.

More info in the now-defunct for sale post:

https://www.homebrewtalk.com/showthread.php?t=537323

broadbill

Well-Known Member

A 5 gal bucket would have too much headspace. You can get 3.5 gal plastic buckets from Uline, but I don't know if they are food-safe.

Another possibility is a 3 gal carboy. I sometimes do 2.5 gal batches and the 3 gal glass isn't as unwieldy as the full size carboys.

The "too much headspace" assumption has always seemed a bit specious to me. How much is too much? If 5 or 5.5 gallons in a 6.5 gallon fermenter isn't too much, why is 3 gallons in a 5 gallon too much?

To my way of thinking, fermenting beer is going to produce krausen and a carbon dioxide blanket. Carbon dioxide is heavier than air and should sit there until disturbed or it dissipates.

Of course there will be exceptions (very long aging time, etc), but I think you would be ok with a large headspace with the "normal" fermentation schedule, but that is just a hunch of mine.

sakeyfour

Well-Known Member

I do 2 Gal batches and use a 2 gallon glass cookie jar I got from Wally World for $10 I think they have gone up since. I put a plastic plate over the top without a blow off tube. I can also put it on my DIY stir plate with a 2in bar when I do 2 gal batches of mead.

TonyKZ1

Well-Known Member

Brew Demon 2.5 gallon conical works for me.

http://www.amazon.com/dp/B00DCC50BC/?tag=skimlinks_replacement-20

I also have one of these, they work great, link to BrewDemon.

Last edited by a moderator:

Spartan300man

Well-Known Member

I got a couple from a local bakery. A small store-front donut/cake shop. They had 1 gal, 3 and 4 gallon sizes. Also, I have heard that the bigger WalMarts with a bakery area, and probably a local supermarket, will have them. They get them filled with icing or other ingredients (glaze or molasses), and often give them away. You know they are food safe. Just get one from the bakery, so the ingredients are likely sugar-based, you don't want one that has a salty or oily ingredient, they are too difficult to clean and remove odors. I filled a 5-gallon molasses bucket with some OxyClean and water and the smell was gone (event though the smell was delicious, I did it for sanitation more than the smell). I drilled a small hole in the top for my airlock, got the grommet from the hardware store for under a dollar.

I do 2.5-3 gallon batches in 5 or 6 gallon carboys. You don't need to worry about headspace in the primary if you're using an airlock. The massive amount of CO2 produced during fermentation will purge all of the oxygen out. So as long as you don't open it too much or leave it in the primary for a really long time it'll be fine. You'll need something smaller if you want to secondary. I almost always do primary only though.

The "too much headspace" assumption has always seemed a bit specious to me. How much is too much? If 5 or 5.5 gallons in a 6.5 gallon fermenter isn't too much, why is 3 gallons in a 5 gallon too much?

To my way of thinking, fermenting beer is going to produce krausen and a carbon dioxide blanket. Carbon dioxide is heavier than air and should sit there until disturbed or it dissipates.

Of course there will be exceptions (very long aging time, etc), but I think you would be ok with a large headspace with the "normal" fermentation schedule, but that is just a hunch of mine.

The most important factor in this is going to be the material of your fermentation vessel. Here's some important things to keep in mind:

*Glass and metal create a barrier impermeable to gas, plastic does not. The diffusion rate of plastic is mostly (although not entirely) dependent on the type of polymer and the thickness.

*Gas to gas diffusion is fundamentally different than a liquid absorbing a gas. Gas will diffuse more readily into other gasses than they will absorb into a liquid.

If you are using glass or metal you don't really need to worry about headspace. There is only a small amount of plastic for gas to gas diffusion to take place. With glass carboys, the bung stopper is very thick which significantly decreases the diffusion rate of the material. With metal fermentation vessels, you can keep them under pressure and avoid diffusion entirely.

With a plastic bucket or plastic carboy, you have a large amount of area that will be subjected to gas to gas diffusion. Although it would make sense to think of CO2 acting like a "blanket", it doesn't work that way. You are correct that initially there is going to be a very high level of CO2 inside the vessel. However, other gasses that have a lower density than the CO2 inside the vessel will want to diffuse in more quickly. It's governed by this equation:

v1/v2 = sqrt(d2/d1)

where v = rate of diffusion and d = density.

Over time the gasses will diffuse until the density is equal to the atmosphere.

How quickly this happens I'm not sure. The most important factor would be creating an airtight seal. Plastic carboys are probably are usually able to create a good seal. Buckets and big mouth bubblers ... not so much. I would be extremely weary of using a bucket or BMB to ferment small batches in.

These might work if they're available. Just have to drill your own hole in the lid

http://www.amazon.com/gp/product/B00RC3FQ5C/?tag=skimlinks_replacement-20

http://www.amazon.com/gp/product/B00RC3FQ5C/?tag=skimlinks_replacement-20

Last edited by a moderator:

I also have one of these, they work great, link to BrewDemon.

+1 on the BrewDemon. I did my first few extract batches with it. I'm currently fermenting in 1 gallon jugs but am planning a mild soon and will use this for sure.

Anyone try these screw-top buckets from Uline? No idea if they are food-safe, but the airtightness makes it an intriguing possibility. Plus, not having to pry lids off--just unscrew.

Edit: I just noticed the listing states that they are "FDA compliant," whatever that means.

Edit: I just noticed the listing states that they are "FDA compliant," whatever that means.

broadbill

Well-Known Member

The most important factor in this is going to be the material of your fermentation vessel. Here's some important things to keep in mind:

*Glass and metal create a barrier impermeable to gas, plastic does not. The diffusion rate of plastic is mostly (although not entirely) dependent on the type of polymer and the thickness.

*Gas to gas diffusion is fundamentally different than a liquid absorbing a gas. Gas will diffuse more readily into other gasses than they will absorb into a liquid.

If you are using glass or metal you don't really need to worry about headspace. There is only a small amount of plastic for gas to gas diffusion to take place. With glass carboys, the bung stopper is very thick which significantly decreases the diffusion rate of the material. With metal fermentation vessels, you can keep them under pressure and avoid diffusion entirely.

With a plastic bucket or plastic carboy, you have a large amount of area that will be subjected to gas to gas diffusion. Although it would make sense to think of CO2 acting like a "blanket", it doesn't work that way. You are correct that initially there is going to be a very high level of CO2 inside the vessel. However, other gasses that have a lower density than the CO2 inside the vessel will want to diffuse in more quickly. It's governed by this equation:

v1/v2 = sqrt(d2/d1)

where v = rate of diffusion and d = density.

Over time the gasses will diffuse until the density is equal to the atmosphere.

How quickly this happens I'm not sure. The most important factor would be creating an airtight seal. Plastic carboys are probably are usually able to create a good seal. Buckets and big mouth bubblers ... not so much. I would be extremely weary of using a bucket or BMB to ferment small batches in.

I'm not following your reasoning about plastic vs. metal vs. glass and gas to gas diffusion. If you are talking across gas diffusion across the wall of the fermenter then it is not gas to gas diffusion but gas to plastic to gas/atmosphere, no?

I'm also not following how fermenter material is impacting the headspace diffusion specifically, without addressing the issue of gas diffusion across the material itself.

How quickly this happens I'm not sure.

...and THAT is the crux of it.

There have been discussions of oxygen permeability of plastic fermenters here in the past. I don't remember the exact calculations, but the take away was that everything you expressed mathematically above IS happening, but the RATE at which it is happening isn't fast enough to impact things in the time-scale we are talking about with making beer.

I'm not following your reasoning about plastic vs. metal vs. glass and gas to gas diffusion. If you are talking across gas diffusion across the wall of the fermenter then it is not gas to gas diffusion but gas to plastic to gas/atmosphere, no?

I'm also not following how fermenter material is impacting the headspace diffusion specifically, without addressing the issue of gas diffusion across the material itself.

...and THAT is the crux of it.

There have been discussions of oxygen permeability of plastic fermenters here in the past. I don't remember the exact calculations, but the take away was that everything you expressed mathematically above IS happening, but the RATE at which it is happening isn't fast enough to impact things in the time-scale we are talking about with making beer.

Gas diffuses into other gas through plastic because it's porous. The pores are too small for large molecules to travel through but O2 and CO2 are small enough molecules to travel through the material.

The way I think about it is like a swarm of small bugs trapped in a mesh cage. The mesh's openings are only big enough to let one of the small bugs through if it hits the opening at a particular angle. The bugs are free to pass through the mesh, but only a small number will hit the mesh's holes in the right way to pass through at any given time.

It's not a perfect analogy but I think it's a good way to visualize gas traveling through plastic.

I agree that this probably isn't a huge issue since beer is made in weeks. A bad seal (i.e. buckets and big mouth bubblers where you see the airlock sink to the bottom after a few days) is probably a much bigger issue.

ericbw

Well-Known Member

- Joined

- Dec 11, 2012

- Messages

- 3,592

- Reaction score

- 1,225

No one ever seems to have a good answer about how quickly the CO2 in a bucket will be mixed with O2 from the atmosphere. Don't age long term in a bucket, but is it happening in weeks? Anyone know?

Obviously metal and glass are better options for keeping it from happening. But cost and availability compared to the benefit?

Obviously metal and glass are better options for keeping it from happening. But cost and availability compared to the benefit?

- Joined

- Dec 26, 2013

- Messages

- 4,302

- Reaction score

- 5,123

hanuswalrus

Well-Known Member

I brew 3 - 3.5 gallon batches and have always used 6 gallon buckets for primary. If I do need to secondary, I have a couple 3 gal glass car boys. I was under the impression that 6 gallon was ok to ferment smaller batches because the CO2 from fermentation protects the beer from oxygen exposure inside the bucket. Is this not the case? My beer has never tasted oxidized using these bigger buckets.

broadbill

Well-Known Member

I brew 3 - 3.5 gallon batches and have always used 6 gallon buckets for primary. If I do need to secondary, I have a couple 3 gal glass car boys. I was under the impression that 6 gallon was ok to ferment smaller batches because the CO2 from fermentation protects the beer from oxygen exposure inside the bucket. Is this not the case? My beer has never tasted oxidized using these bigger buckets.

I think this is a classic case of where theory gets thrown out the window for results in actual practice. Marshall and company at http://brulosophy.com/ is actually making a very successful blog it, in fact.

I brew 3 - 3.5 gallon batches and have always used 6 gallon buckets for primary. If I do need to secondary, I have a couple 3 gal glass car boys. I was under the impression that 6 gallon was ok to ferment smaller batches because the CO2 from fermentation protects the beer from oxygen exposure inside the bucket. Is this not the case? My beer has never tasted oxidized using these bigger buckets.

No, you're fine. I do the same thing with a plastic 6 gallon carboy. As long as you have a good seal it would take much longer than a couple of weeks for an appreciable amount of oxygen to diffuse through the plastic.

Calypso

Well-Known Member

I brew 3 - 3.5 gallon batches and have always used 6 gallon buckets for primary. If I do need to secondary, I have a couple 3 gal glass car boys. I was under the impression that 6 gallon was ok to ferment smaller batches because the CO2 from fermentation protects the beer from oxygen exposure inside the bucket. Is this not the case? My beer has never tasted oxidized using these bigger buckets.

I really think you answered your own question.

AKA: If it ain't broke, don't fix it.

wobdee

Junior Member

I like the 3.2 gal Speidel. http://www.morebeer.com/products/speidel-plastic-storage-tank-12l-32-gal.html

No one ever seems to have a good answer about how quickly the CO2 in a bucket will be mixed with O2 from the atmosphere. Don't age long term in a bucket, but is it happening in weeks? Anyone know?

Obviously metal and glass are better options for keeping it from happening. But cost and availability compared to the benefit?

It's hard to give an exact number because there's so many variables. Most plastic carboy/bucket manufacturers aren't going to be interested in oxygen permeability and pay to test their products, let alone make that information available to the public. On top of that the temperature, volume of liquid, and density of CO2 are going to play a role. Basically, you would have to figure this out on a case to case basis.

In reality I agree that it's largely a non-issue if you're getting a good seal.

EndOfBeans

Well-Known Member

- Joined

- Jun 12, 2015

- Messages

- 52

- Reaction score

- 9

Sorry if my pictures are messed up but this is what i use. 2.5 gallon pickle jars. On amazon. Heavy thick glass and they have wide opening and handles.

Similar threads

- Replies

- 25

- Views

- 1K

- Replies

- 5

- Views

- 363

- Replies

- 3

- Views

- 424

- Replies

- 8

- Views

- 394