Cider Wraith

Well-Known Member

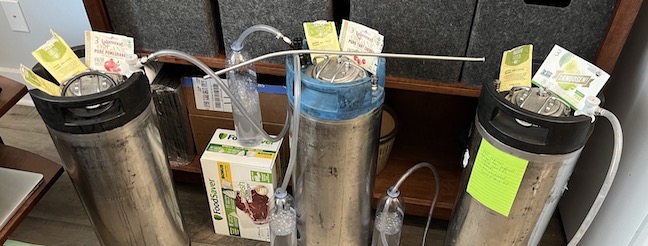

This started with me thinking I would upgrade our home fermenting efforts with a pricy conical fermenter and discovering the revolution of keg fermenting. Also, I only make ciders so my needs are simplistic compared to you brewers. I appreciate corny keg fermenting is a relatively developed art but I’m just at the beginning of my journey and have a lot to learn so am doing my research. Well, yesterday stumbled across the idea of fermenting and serving in the same keg and that seems like it’s up there with the invention of the wheel

Seems like the obstacle to overcome with keg fermenting is elimination (or dramatic reduction) of sediment, “lees”. If doing an ordinary cider I ferment juices only so my sediment is fine and easily makes it through a line. But how to do it? Options?

Trim a conventional dip tube - it that case one would be committing to always losing a specified quantity of liquid but would probably produce good results. And, if committing to never opening the keg to expose contents to air it would require modifying several dip tubes that couldn’t be used conventionally again

Bend a conventional tube to one side of the bottom and ferment and transfer out with the keg tilted - same problem, always losing a specified quantity of liquid - seems iffy with keg being disturbed, potential leaking

Floating dip tube - an idea to explore further, but do they sometimes twist or bind or otherwise fail to get all the usable liquid? Maybe floating dip tubes all-the-rage?

Finally, what I’ve been thinking is, after fermentation, applying couple PSI and attaching a mobile picnic tap and pouring into a yeast saving vessel until clear liquid is produced. My guess would be although that would initially work, what would be happening is that a crater would be formed in the sediment close to the dip tube, and a sizable amount of sediment would remain on the sides that would eventually get back into the tube as the liquid level lowered and the keg was jostled. This seems like the simplest option to start with and ... if so ... am I going to wind up drinking some sediment, yeah.

So maybe I’m all off-track and there’s a dramatically better way to do any of this. Thoughts, musings appreciated -

Seems like the obstacle to overcome with keg fermenting is elimination (or dramatic reduction) of sediment, “lees”. If doing an ordinary cider I ferment juices only so my sediment is fine and easily makes it through a line. But how to do it? Options?

Trim a conventional dip tube - it that case one would be committing to always losing a specified quantity of liquid but would probably produce good results. And, if committing to never opening the keg to expose contents to air it would require modifying several dip tubes that couldn’t be used conventionally again

Bend a conventional tube to one side of the bottom and ferment and transfer out with the keg tilted - same problem, always losing a specified quantity of liquid - seems iffy with keg being disturbed, potential leaking

Floating dip tube - an idea to explore further, but do they sometimes twist or bind or otherwise fail to get all the usable liquid? Maybe floating dip tubes all-the-rage?

Finally, what I’ve been thinking is, after fermentation, applying couple PSI and attaching a mobile picnic tap and pouring into a yeast saving vessel until clear liquid is produced. My guess would be although that would initially work, what would be happening is that a crater would be formed in the sediment close to the dip tube, and a sizable amount of sediment would remain on the sides that would eventually get back into the tube as the liquid level lowered and the keg was jostled. This seems like the simplest option to start with and ... if so ... am I going to wind up drinking some sediment, yeah.

So maybe I’m all off-track and there’s a dramatically better way to do any of this. Thoughts, musings appreciated -

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)